Polishing equipment suitable for special-shaped glass

A special-shaped glass and equipment technology, which is applied in the field of polishing machines, can solve the problems of multi-working space, increased maintenance workload, occupation, etc., and achieve the effect of reducing the workload of later maintenance and reducing the number of polishing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

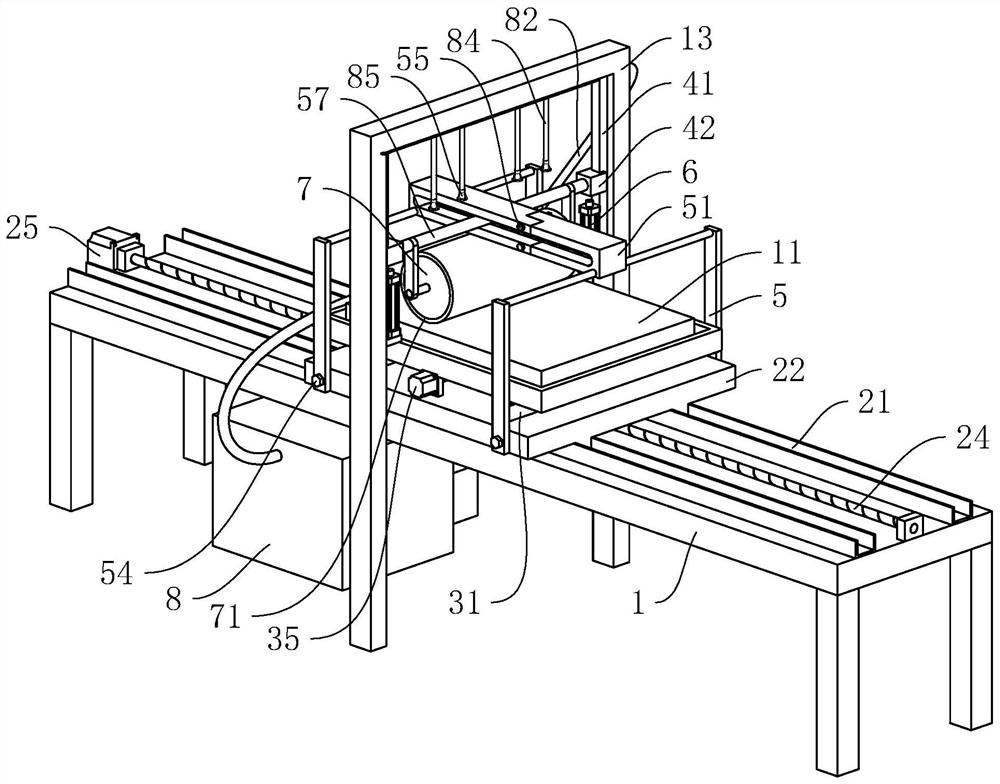

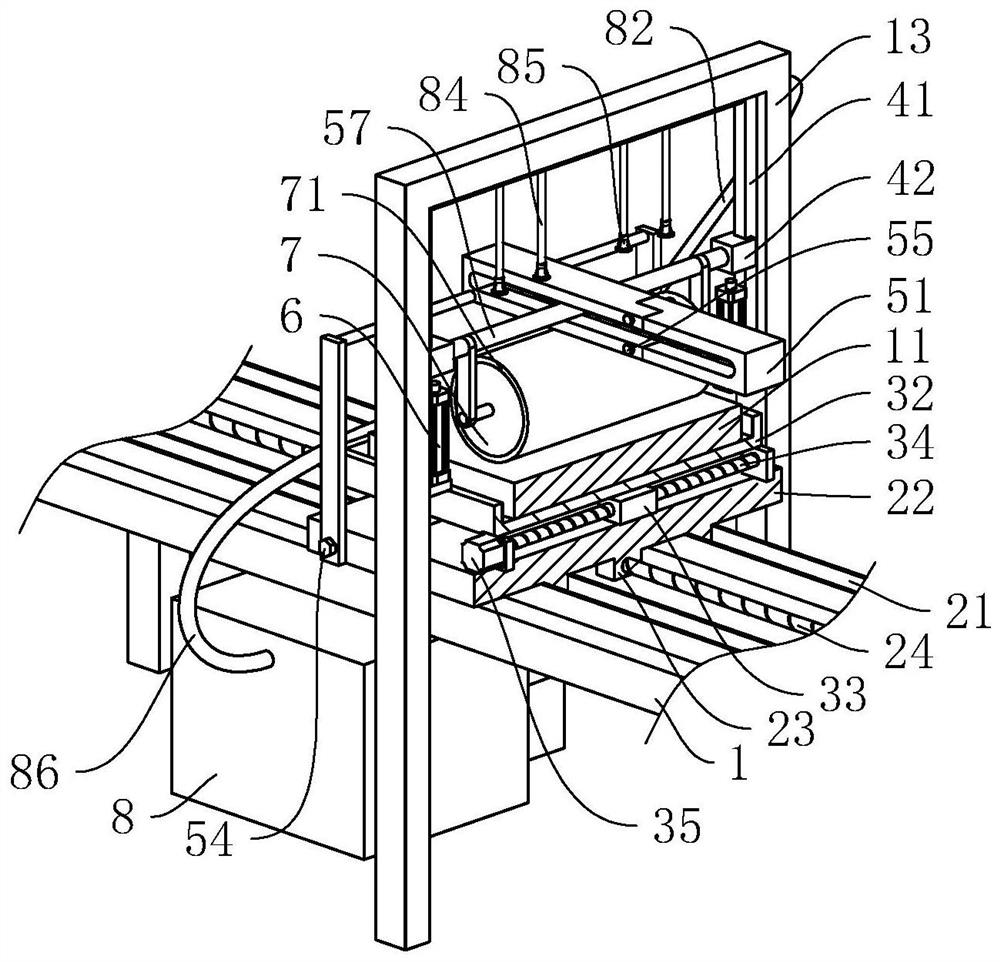

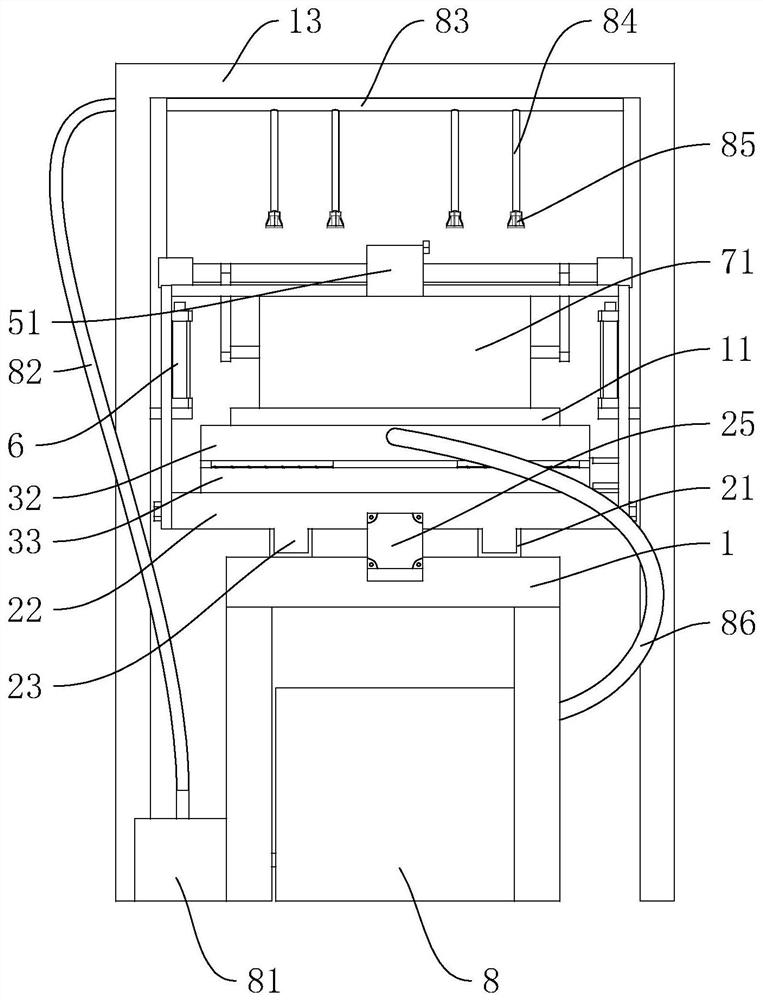

[0040] refer to figure 1, a kind of polishing equipment suitable for special-shaped glass, including a polishing table 1 placed on the ground of the working environment, a first slide rail 21 is fixed on the top of the polishing table 1, and at the same time, one end of the top of the polishing table 1 is rotatably connected with a through The first screw rod 24 for the bearing housing to rotate is connected with a first motor 25 at the end of the first screw rod 24 away from the bearing housing. Wherein, in this embodiment, there are two first slide rails 21, the two first slide rails 21 and the first screw rod 24 extend along the length direction of the polishing table 1, and the first screw rod 24 is sandwiched between two There are 21 first slide rails.

[0041] At the same time, a first slider 23 is threadedly connected to the first screw 24 , and a first slider 22 is integrally formed on the first slider 23 , and the first slider 22 is slidably connected to the first sl...

Embodiment 2

[0067] refer to Figure 5 and Figure 6 , The difference from Embodiment 1 is that in this embodiment, the wheel groove is a curved groove 52 adapted to the curved glass 12 to be processed.

[0068] The implementation principle of a kind of polishing equipment suitable for special-shaped glass in the embodiment of the present application is as follows:

[0069] The worker activates the hydraulic cylinder 6 to make the hydraulic rod of the hydraulic cylinder 6 abut against the third slide block 42, thereby supporting the slide rod 57 and the polishing roller 7, and then dismantling the positioning bolt 54 and the fastening bolt 55 to straighten the wheel groove. The guide block 51 and the bracket 5 of the groove 53 are disassembled from the first slide plate 22 , and finally the guide block 51 whose wheel groove is a curved groove 52 is reassembled on the first slide plate 22 through the positioning bolt 54 and the fastening bolt 55 .

[0070] After the guide block 51 was ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com