High-performance composite cable and manufacturing method thereof

A composite cable and manufacturing method technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of affecting the shielding effect, poor moisture-proof effect, and the shielding layer is easily corroded by water vapor, so as to improve the use safety, The effect of reducing the increase in cable cost and improving the moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

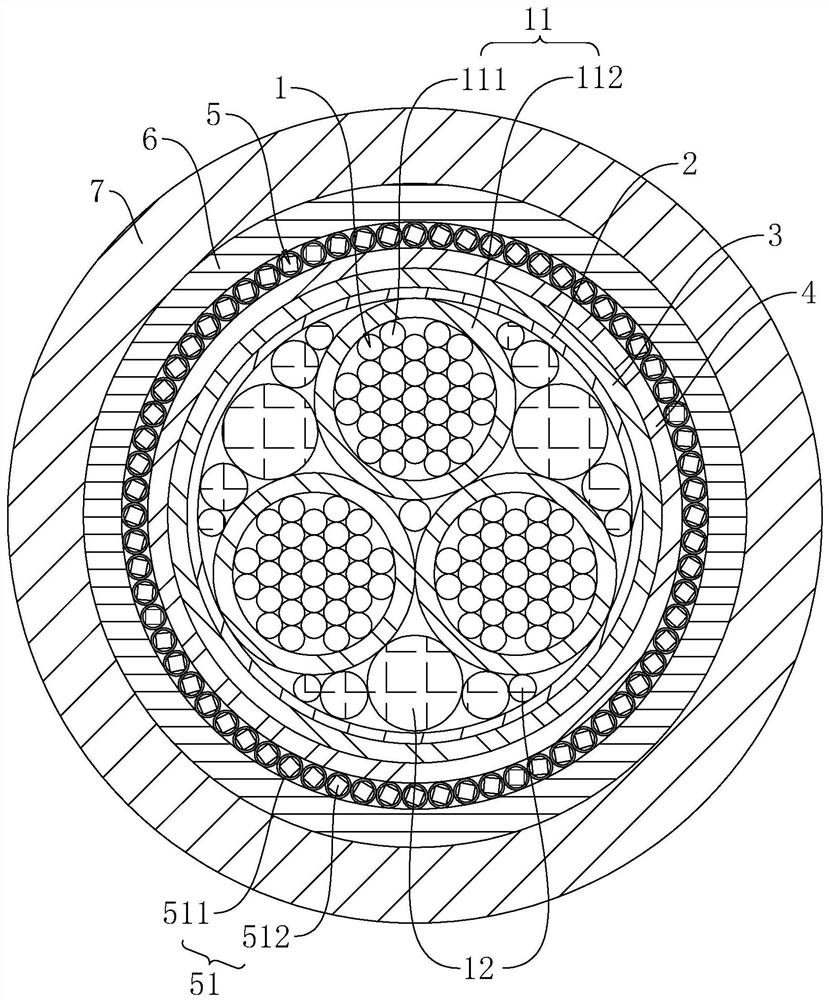

[0044] Embodiment 1 of the present application discloses a high-performance composite cable. refer to figure 1 , The high-performance composite cable includes a cable core 1, a cladding layer 2, a shielding layer 3, an oxygen barrier layer 4, a waterproof layer 5, an armor layer 6 and a sheath layer 7 arranged in sequence from the inside to the outside.

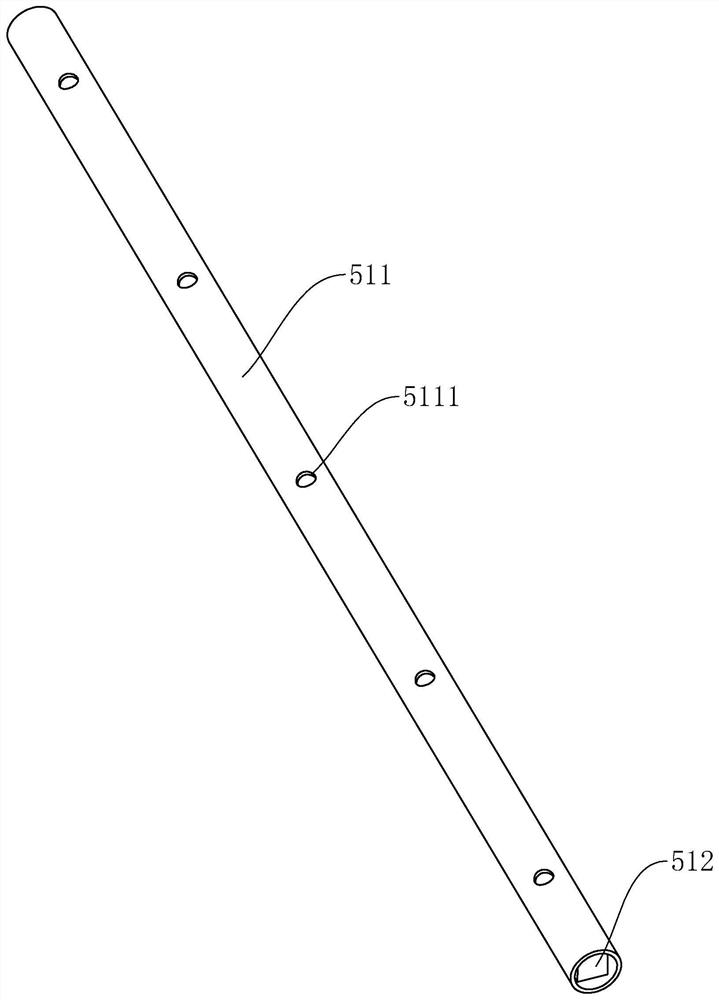

[0045] Among them, the cable core 1 is composed of three single cables 11 and a plurality of filling ropes 12 twisted, the centers of the three single cables 11 are located on the same circumference, and the filling ropes 12 are filled in the gaps around the three single cables 11; the single cables 11 are composed of conductor wires The core is composed of a waterproof insulating layer 112 covering the conductor core. The conductor core is formed by twisting a plurality of conductor monofilaments 111. The waterproof insulating layer 112 is obtained by extruding cross-linked polyethylene. In this embodiment, the conductor mo...

Embodiment 2

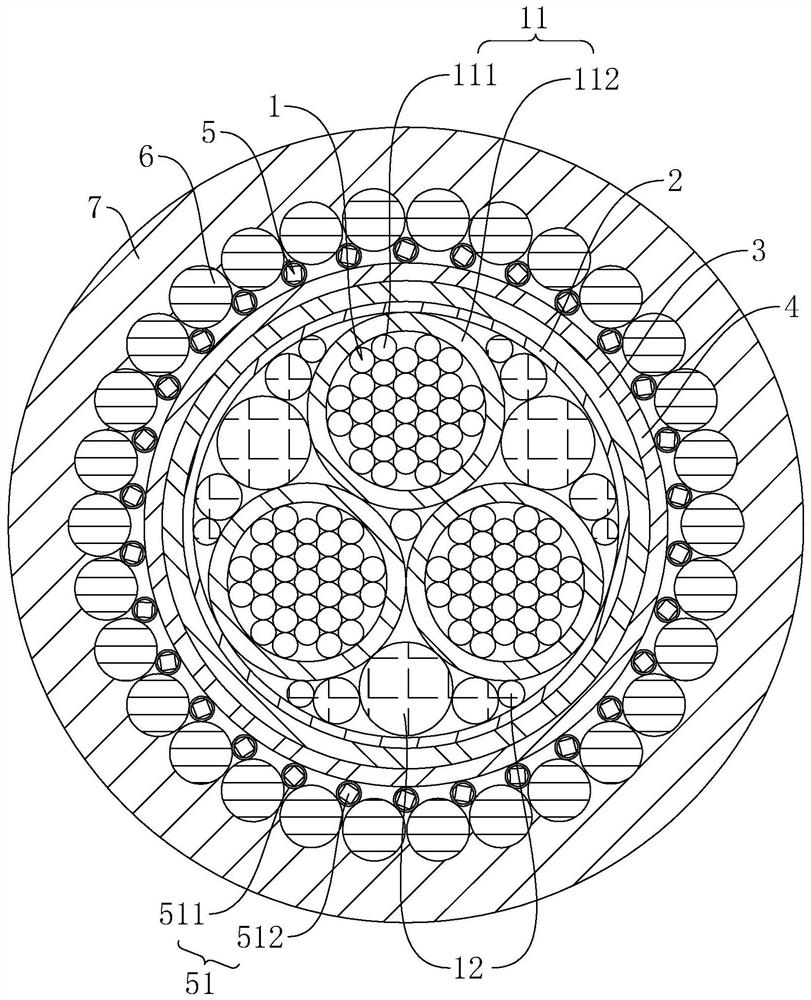

[0059] Embodiment 2 of the present application discloses a high-performance composite cable, referring to image 3 The difference from the high-performance composite cable in Example 1 is that the armor layer 6 is composed of steel wire armor, and the side of the moisture-absorbing tube 51 away from the oxygen barrier layer is embedded in the armor layer 6 and formed by adjacent steel wires. In the gap, and the outer diameter of the steel wire of the armor layer 6 is not greater than 2 times of the outer diameter of the moisture-absorbing pipe 51. In this embodiment, the outer diameter of the armored layer 6 steel wire is 2mm, the outer diameter of the moisture-absorbing tube 51 is 1.1mm, and the wall thickness of the moisture-absorbing tube 51 is 0.25mm

[0060] This embodiment 2 also discloses the manufacturing method of the high-performance composite cable in this embodiment. The difference from the manufacturing method of the high-performance composite cable in embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com