Lead storage battery capable of being normally started in low charge state

A technology of lead-acid batteries and state of charge, applied in the direction of lead-acid batteries, lead-acid battery construction, battery electrodes, etc., can solve problems such as return, capacity attenuation, user complaints, etc., to achieve increased service life, increased cycle times, and improved starting effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A starter lead-acid battery suitable for use in a low state of charge. The starter lead-acid battery is a battery with a valve-controlled sealed structure, and the positive lead paste includes the following components by weight: 1000 parts of lead powder, 112 parts of purified water, 4 parts of auxiliary materials, 90 parts of dilute sulfuric acid and 1.8 parts of short fiber.

[0024] The mixing process of the positive lead paste is as follows: add 1000kg of lead powder, 4kg of alkaline earth metal oxide and sulfate mixture, and 1800g of short fibers into the mixing machine, stir evenly for 5 minutes, then open the water valve, and pour the mixture into the mixing machine at an even speed. Add 112kg of purified water, the water addition time is 1-3 minutes, stir while adding water, the stirring time is 5 minutes, then open the acid addition valve, add dilute sulfuric acid 90kg to the paste machine, the acid addition time is 14-18 minutes, and Turn on the dust extractio...

Embodiment 2

[0028] A starter lead-acid battery suitable for use in a low state of charge. The starter lead-acid battery is a battery with a valve-controlled sealed structure, and the positive lead paste includes the following components by weight: 1050 parts of lead powder, 117 parts of purified water, 5 parts of auxiliary materials, 85 parts of dilute sulfuric acid and 2.0 parts of short fiber. The preparation process of the positive electrode paste is the same as in Example 1, and the penetration of the positive electrode paste of the battery is 17mm.

[0029]The number of positive plates for lead-acid batteries is 78, the number of negative plates is 84, the number of separators is 78, the size of the positive plates is: 148×151×2.5mm, the size of the negative plates is: 150×151×2.0mm, the size of the separators For: 160×320×2.3mm (20kPa). The 20h rate capacity of the lead storage battery thus prepared was 220A·h.

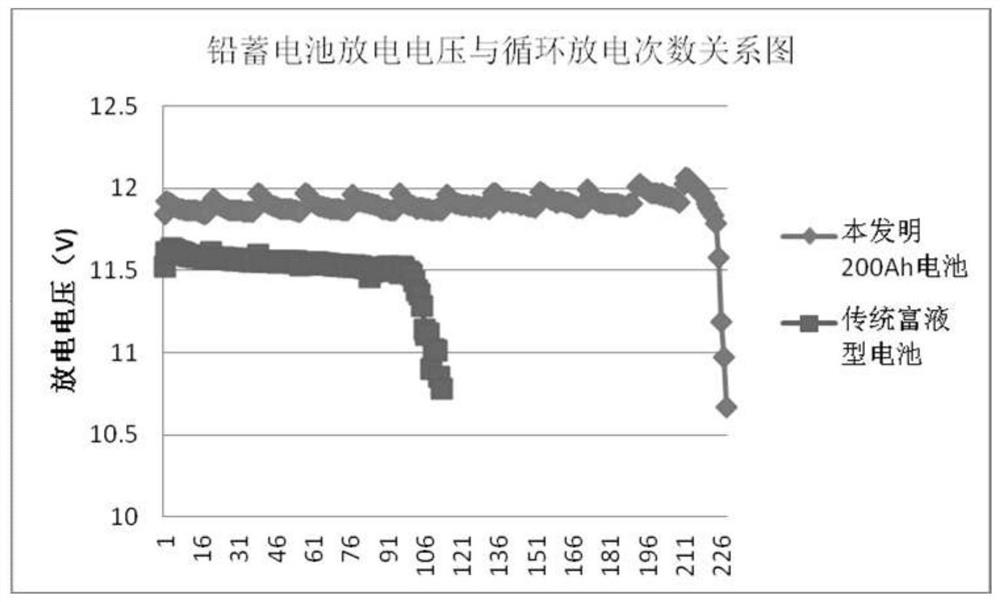

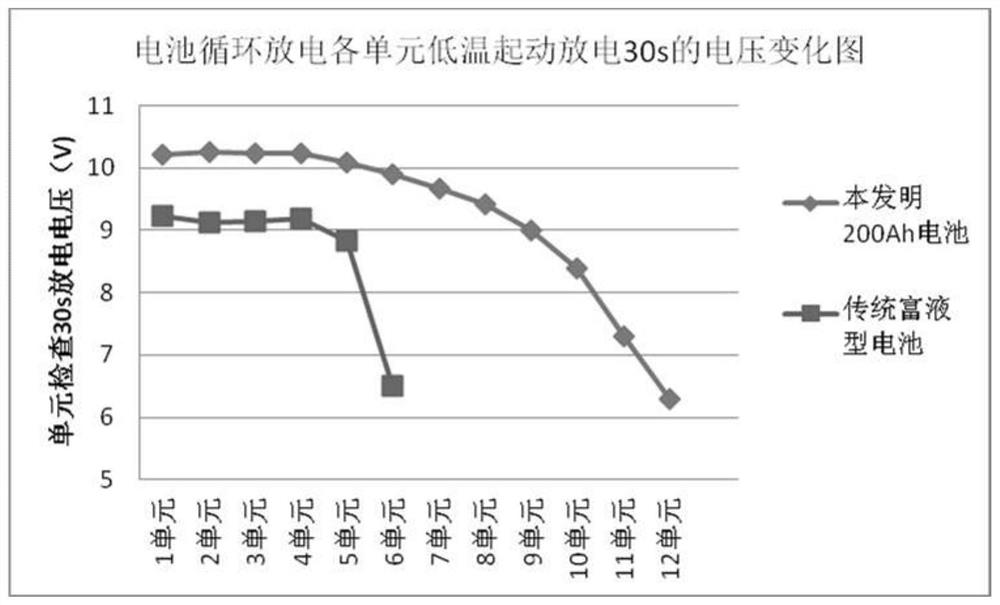

[0030] After the prepared lead-acid battery goes through 205 deep ch...

Embodiment 3

[0032] A starter lead-acid battery suitable for use in a low state of charge. The starter lead-acid battery is a battery with a valve-controlled sealed structure, and the positive lead paste includes the following components by weight: 950 parts of lead powder, 112 parts of purified water, 3 parts of auxiliary materials, 95 parts of dilute sulfuric acid and 1.0 parts of short fiber. The preparation process of the positive electrode paste is the same as in Example 1, and the penetration of the positive electrode paste of the battery is 17mm.

[0033] The number of positive plates for lead-acid batteries is 84, the number of negative plates is 90, the number of separators is 84, the size of positive plates is: 148×151×2.5mm, the size of negative plates is: 150×151×2.0mm, the size of separators For: 160×320×2.3mm (20kPa). The 20h rate capacity of the lead storage battery thus prepared was 240A·h.

[0034] After the prepared lead-acid battery has undergone 228 deep charge and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com