Stator cooling structure, driving motor and new energy automobile

A technology for cooling structures and stators, which is applied in the field of vehicles to achieve uniform cooling, prolong service life, and avoid uneven cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

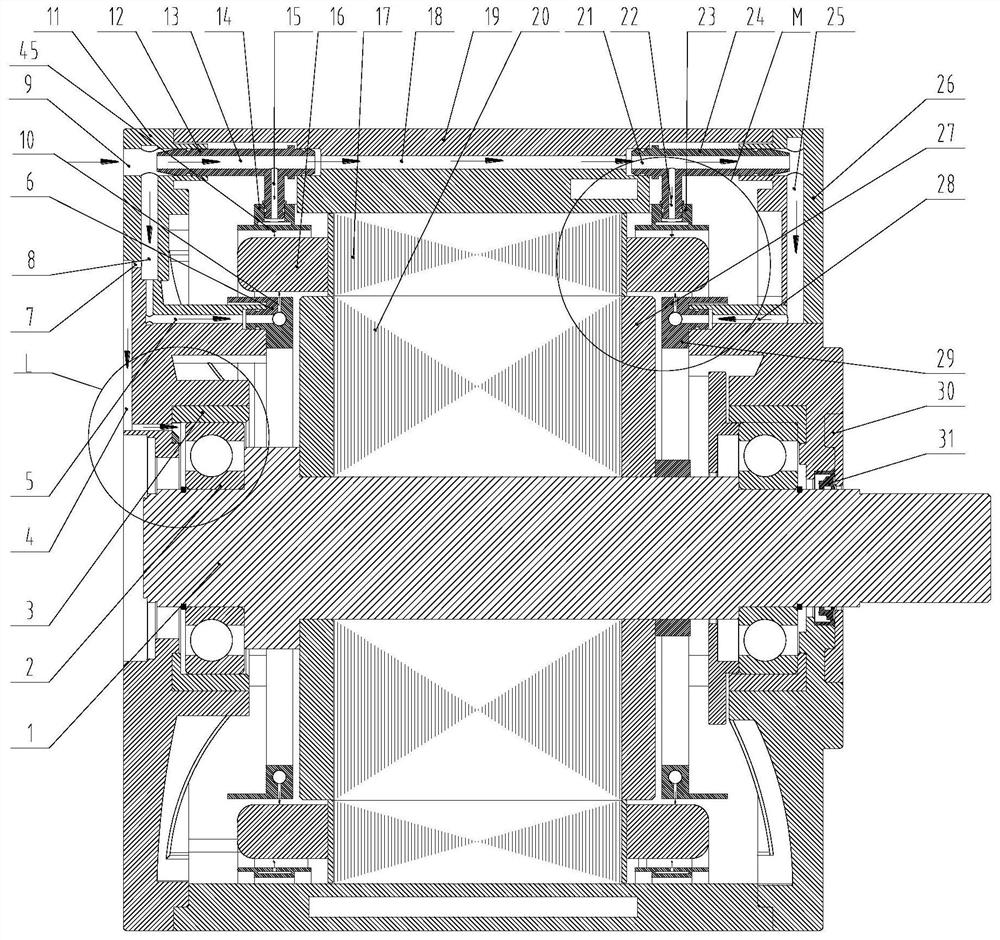

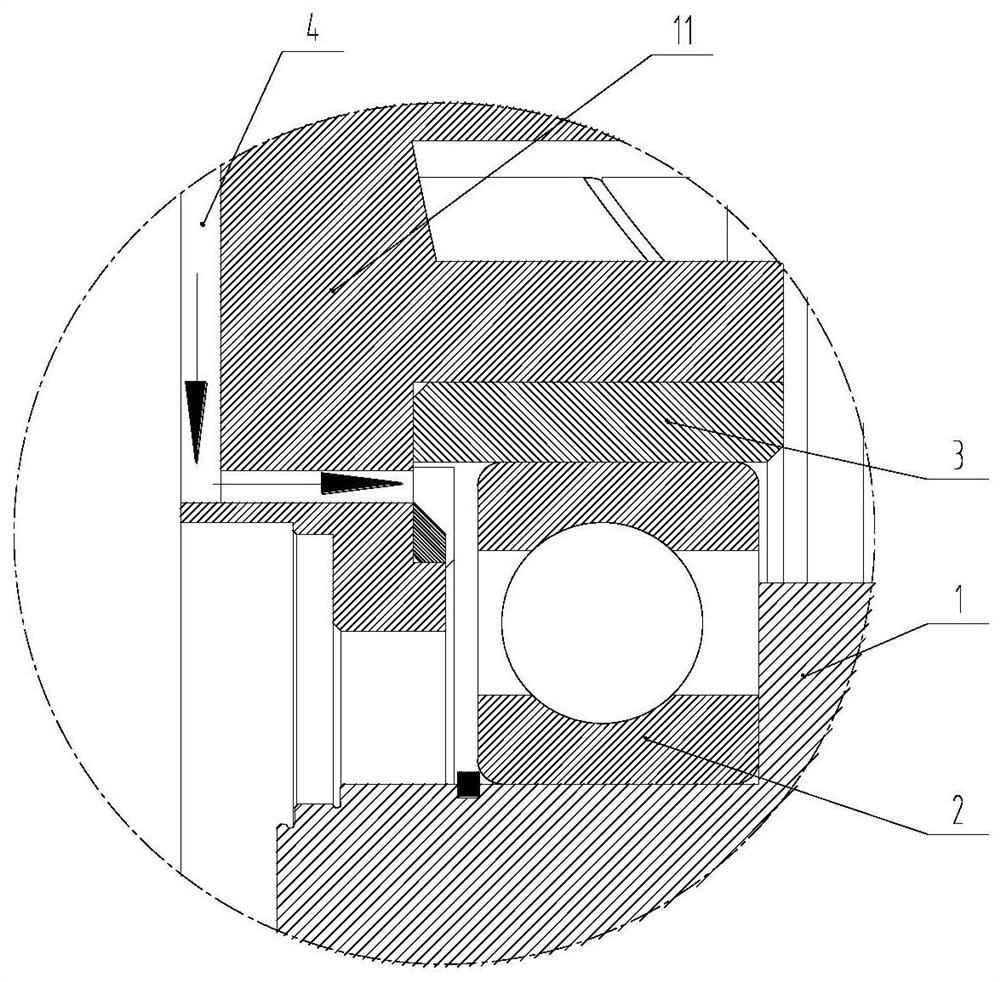

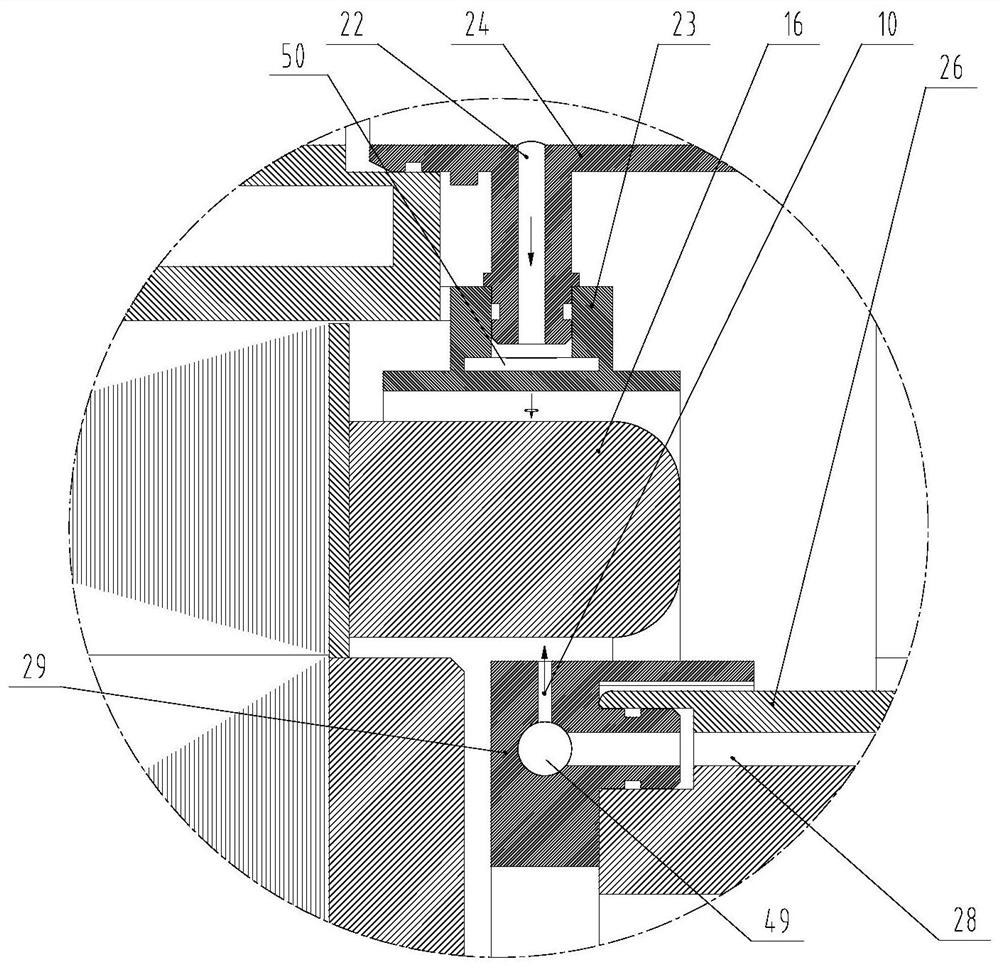

[0053] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, the stator cooling structure is used to cool the stator winding 16, the stator cooling structure includes the motor oil inlet 9, the inner ring oil injection structure and the outer ring oil injection structure, and the inner ring oil injection structure is set On the inner peripheral side of the stator winding 16, the oil injection structure of the outer ring is arranged on the outer peripheral side of the stator winding 16. An oil injection hole 10, the outer ring oil injection structure includes a second oil injection hole 45, the opening of the first oil injection hole 10 faces the inner peripheral wall of the stator winding 16, and the opening of the second oil injection hole 45 faces the outer peripheral wall of the stator winding 16 .

[0054] The stator cooling structure is equipped with an oil injection structure on the inner and outer sides of the stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com