Graded screening device for granulated and shaped granular activated carbon

A granular activated carbon, grading and screening technology, applied in sieves, solid separation, grids, etc., can solve the problems of clogging of screening meshes, reducing the efficiency of granular activated carbon discharge, and difficulty in discharging granular activated carbon. Improve efficiency, increase the effect of classification and screening, and simplify the effect of discharging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the technical means of the present invention, the creation of features, to achieve the purpose and effect readily apparent appreciated that specifically illustrated below with reference to further illustrate the present invention; Incidentally, in the case of no conflict, the embodiments of the present application and Example features may be combined with each other.

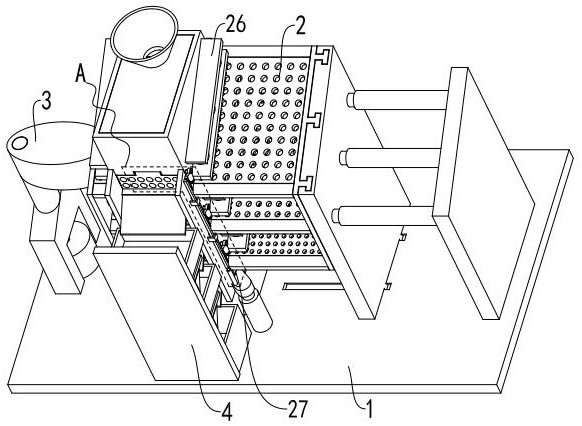

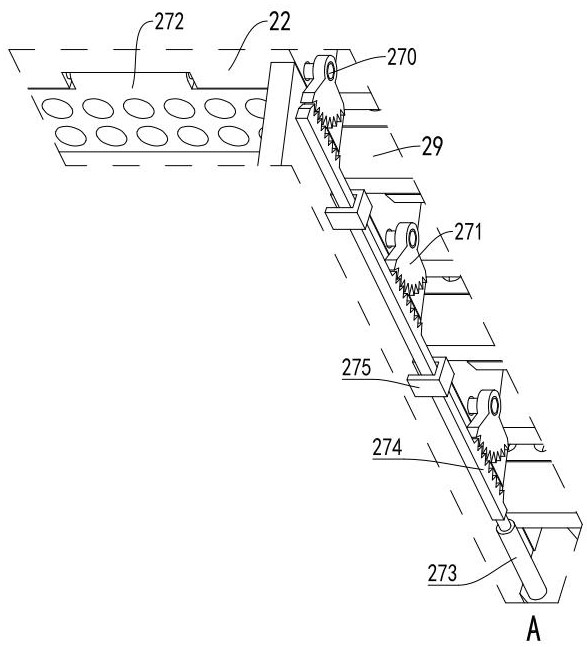

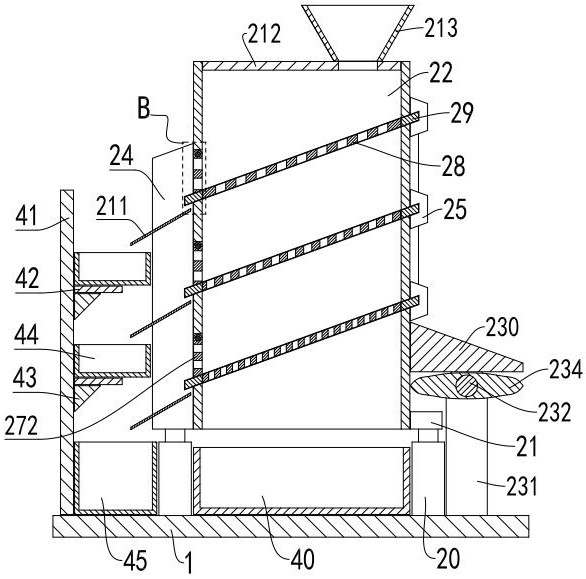

[0025] See figure 1 The granulated activated carbon particles one styling classification screening device, comprising a base 1, a screening mechanism 2, the reciprocating mechanism 3 and the takeup device 4, the upper surface of the base 1 is provided with a screening means 2, sieving mechanism 2 is connected with a reciprocating mechanism 3, the lower end of the reciprocating mechanism 3 is mounted on the base 1, the end face positioned on the base 1 and the screening means is provided with a front side 2 receipt mechanism 4, wherein: said screening mechanism 2 comprising a tension spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com