Nuclear power generator sealing pad machining method

A processing method and sealing tile technology, which is applied in the field of nuclear power generator sealing tile processing, can solve the problems of construction period, waste of manpower lathe resources, repeated sealing tile processing, and tile end face opening, etc., to solve incomplete contact and opening Problems, shortening the processing period, and improving the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

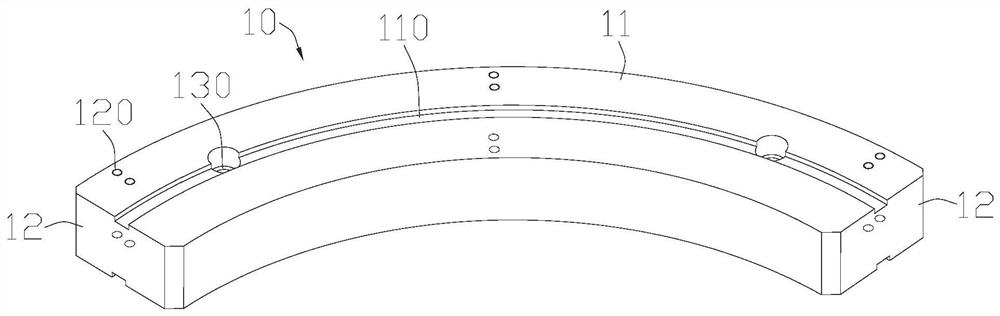

[0035] The nuclear power generator sealing tile processing method of the present invention is used to process the sealing tile whose shape and position data are unqualified (such as deformation, etc.) after one or more operating cycles, and provides processing for the inner circle processing of the sealing tile The margin is to make the sealing tile return to the standard value (design value) and continue to be used normally.

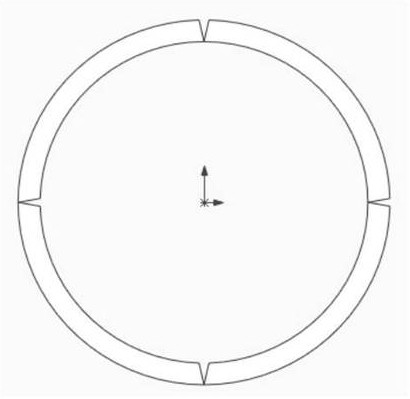

[0036] The sealing tile of a nuclear power generator usually includes four connected tiles, and the four tiles are spliced to form a full-circle sealing tile.

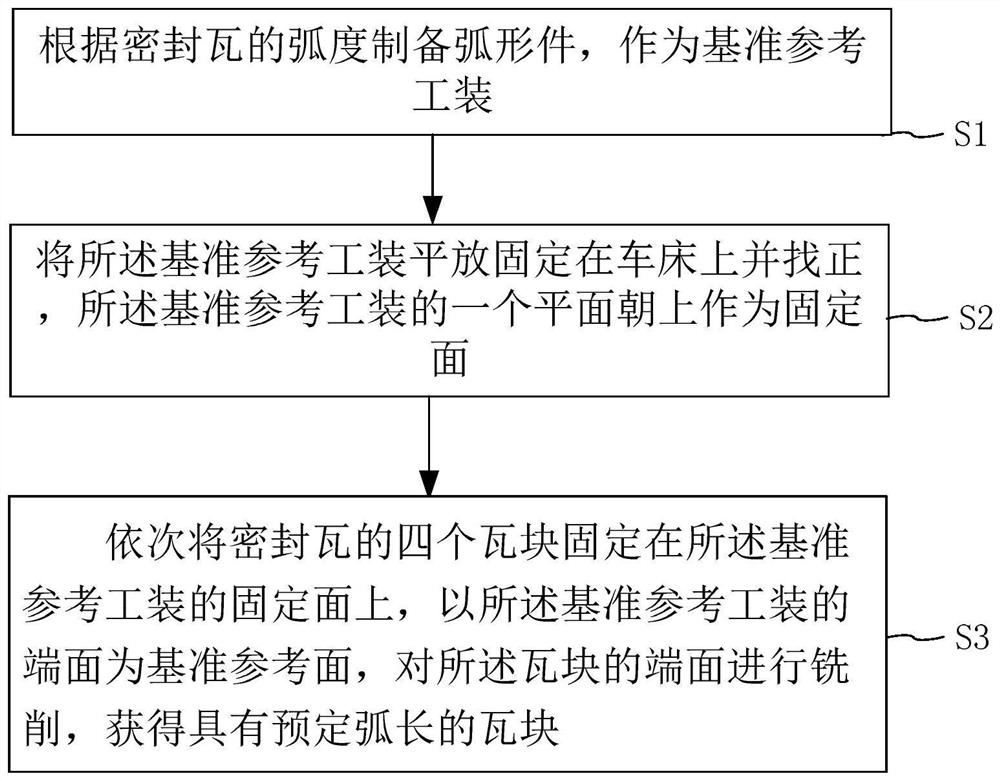

[0037] refer to figure 2 and image 3 , nuclear power generator sealing tile processing method of the present invention may compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com