Box-type rigid tray applied to logistics transportation and using method thereof

A box-type, rigid technology, applied in the direction of rigid containers, transportation and packaging, bottle/can parts, etc., can solve the problems of goods without shock absorption, goods damage, etc., to achieve easy stacking, reduce vibration, avoid The effect of damaged goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

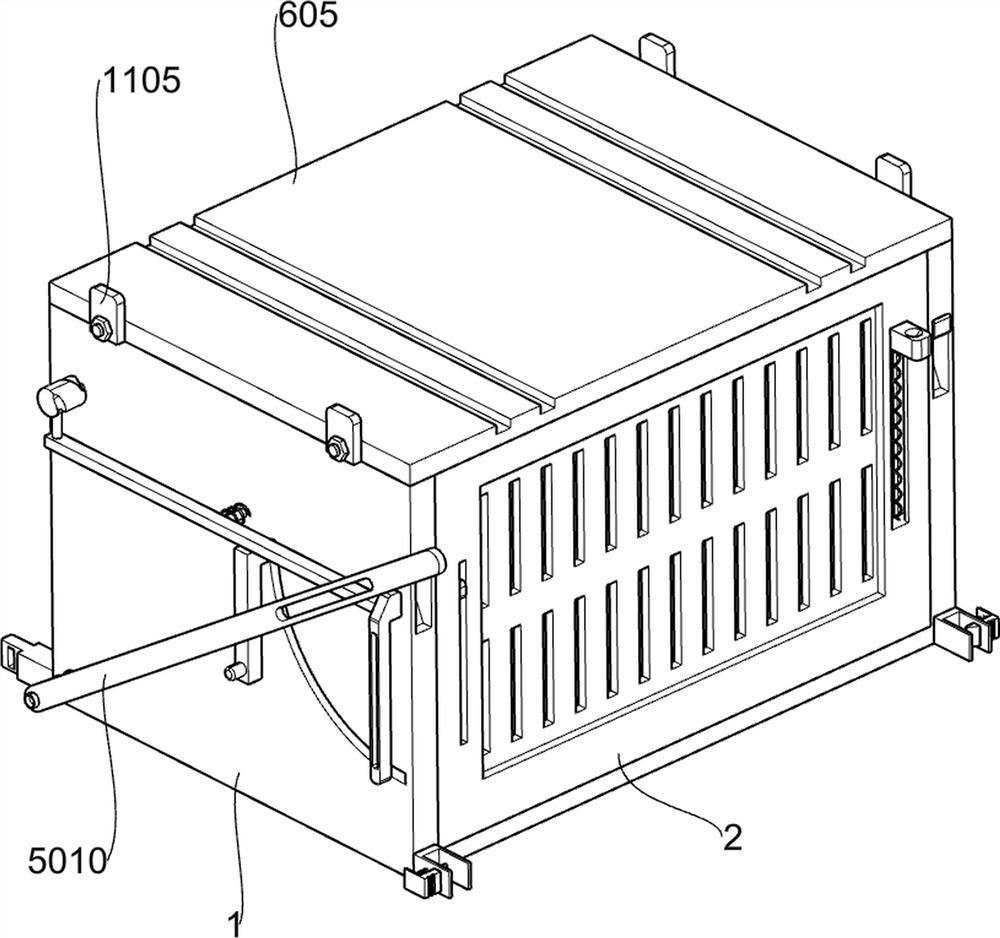

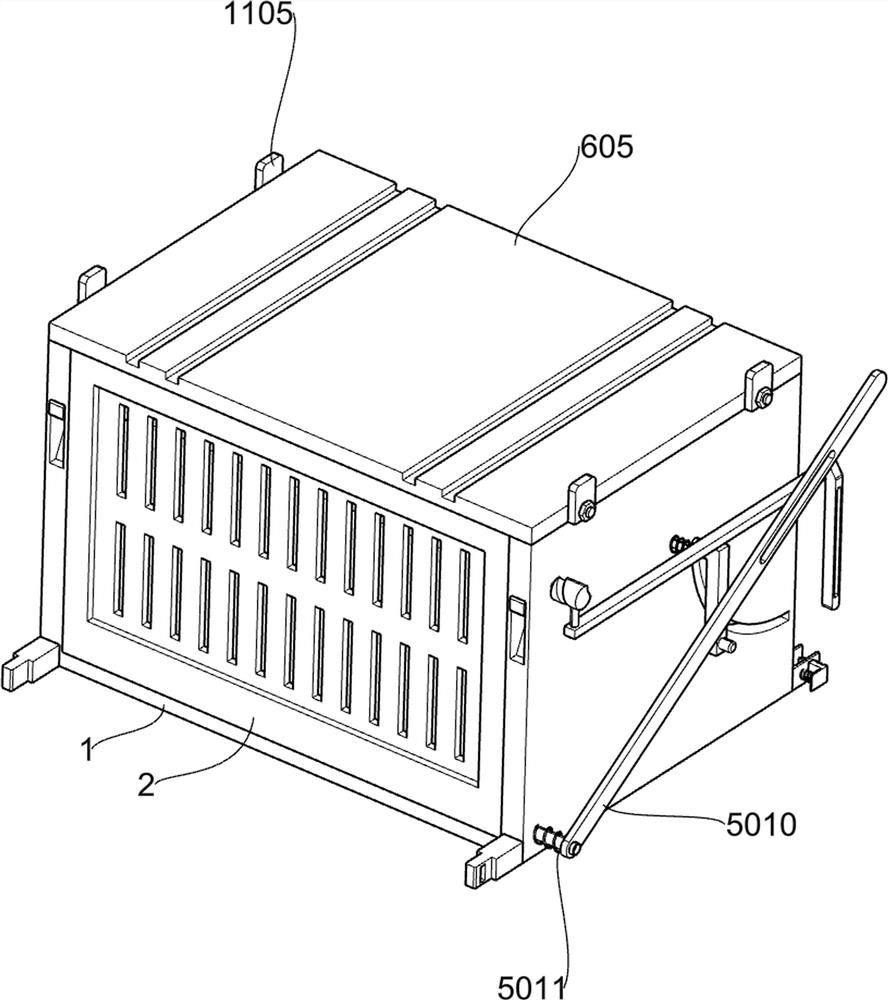

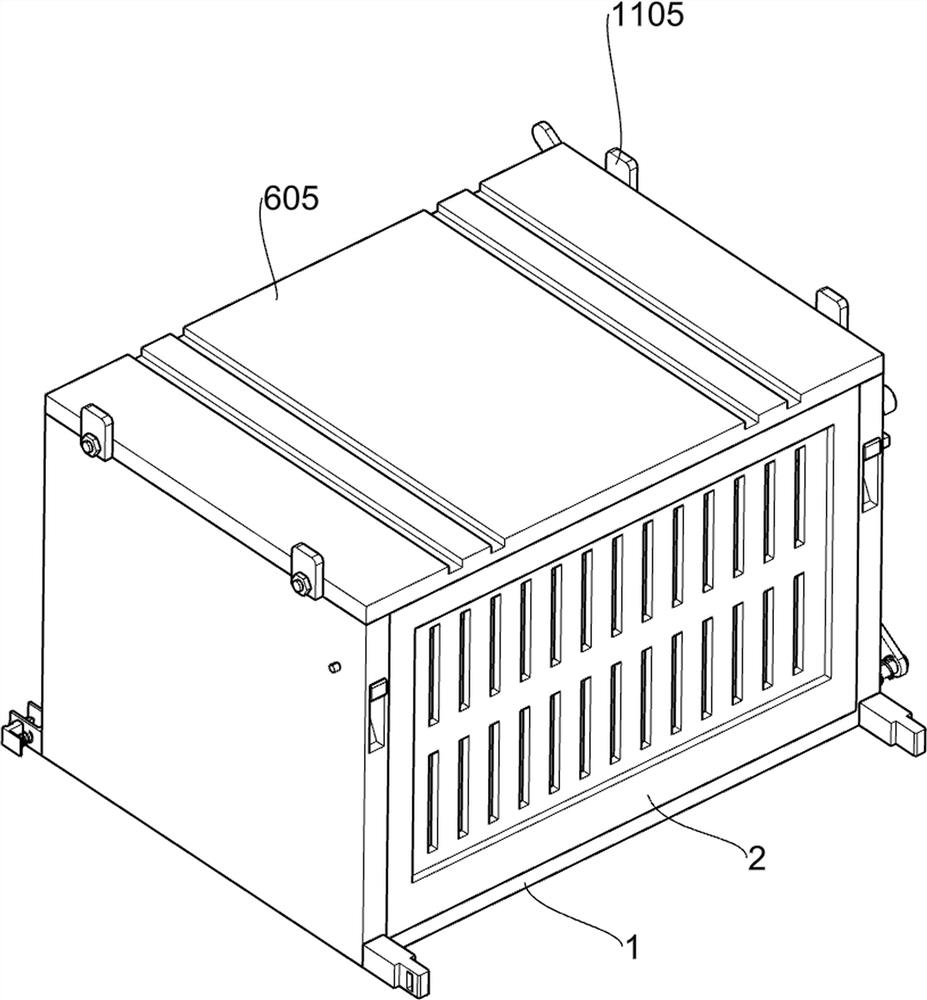

[0052] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 14 with Figure 15 As shown, the present embodiment proposes a box-type rigid tray applied to logistics transport and its use, including a casing housing 1, a strip hole box plate 2, a first divided plate 3, a second division plate 4, auxiliary The handling member 5 and the cover member 6 are configured with strip-shaped hole plate 2 on the casing shell 1, and the bottom surface of the casing 1 is provided with a first divided plate 3, and the first divided plate 3 is used to separate the goods. Two second dividing plates 4 are fixed in the casing case 1, and the second partial cutting plate 4 is also used to separate the cargo, and the box casing 1 is provided with auxiliary conveyance member 5, and the auxiliary handling member 5 is used to place the cargo. The auxiliary handling, the cover member 6 is provided on both sides of the casing she...

Embodiment 2

[0056] Next, in conjunction with the specific mode of operation, further introduction of the scheme in Example 1 is shown in detail below.

[0057] like Figure 11 , Figure 12 , Figure 13 As shown, as a preferred embodiment, in the above manner, further, further, including the inflatable buffer member 7, the first dividing plate 3, and the two second dividing plates 4, and the inflatable buffer member 7, inflation The buffer member 7 includes an airbag 701, a rubber airbag 702, a first one-way valve 703, a pulverizing plate 704, a second compression spring 705, an exhaust pipe 706, an open spacer 707, a reset spring 708, and a second one-way The valve 709, the first dividing plate 3, and the two second partial cutting plates 4, together, the airbag holder 701 is fixed, and the airbag holder 701 is provided with a rubber airbag 702, and the rubber airbag 702 passes through the first divided plate 3, rubber pumping. A first one-way valve 703 is provided on the air bag 702, and the fi...

Embodiment 3

[0063] Next, in connection with the specific mode of operation, further introduction of the schemes in Examples 1 and Example 2 is shown in detail below.

[0064] Specifically, the use of box-type rigid trays used in logistics transportation is operating:

[0065]When using this device requires the transport of goods, the staff to manually pull up the cover 605 to open, the cover 605 will drive the first link 603 and second link 604 to swing. Slotted staff holding the swing plate 5010 and the pressing, the pressure plate frame 508 since the housing 2 and the strip-shaped aperture is hingedly connected at the inclined surface, grooved wobble plate 5010 pushes the lower platen ramp down swinging frame 508, when the ramp platen holder 508 swing integrally downwardly, the pressure plate frame 508 at a lower slope ramp will push the upper moving force applied to the strip 506, in the bevel 508 under the action of the inclined surface of the lower platen frame, the downward force will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com