Wastewater treatment device for building construction

A technology for wastewater treatment and building construction, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve unfavorable safety production, equipment shaking, and reduce flocculation efficiency To improve the efficiency of wastewater treatment and prevent equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

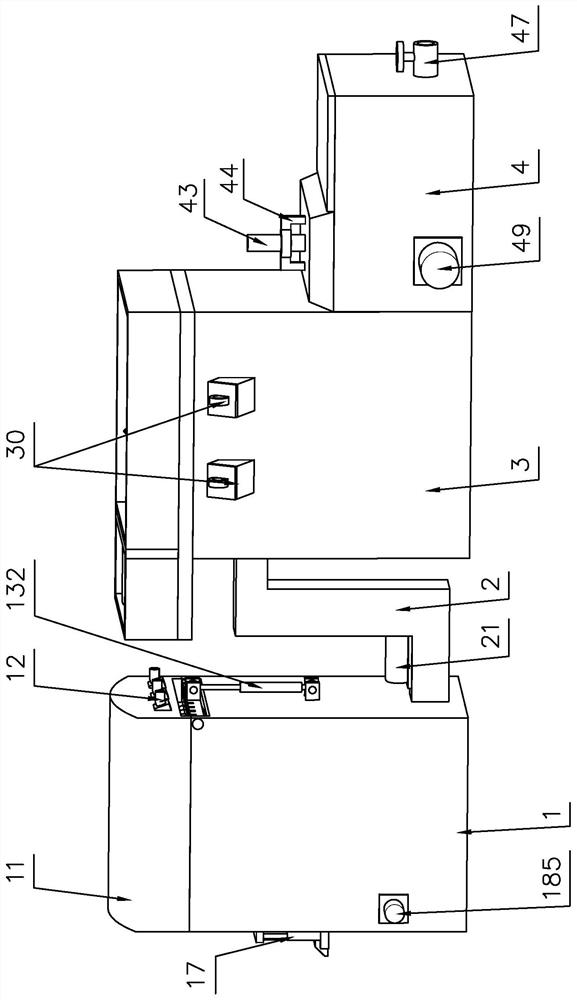

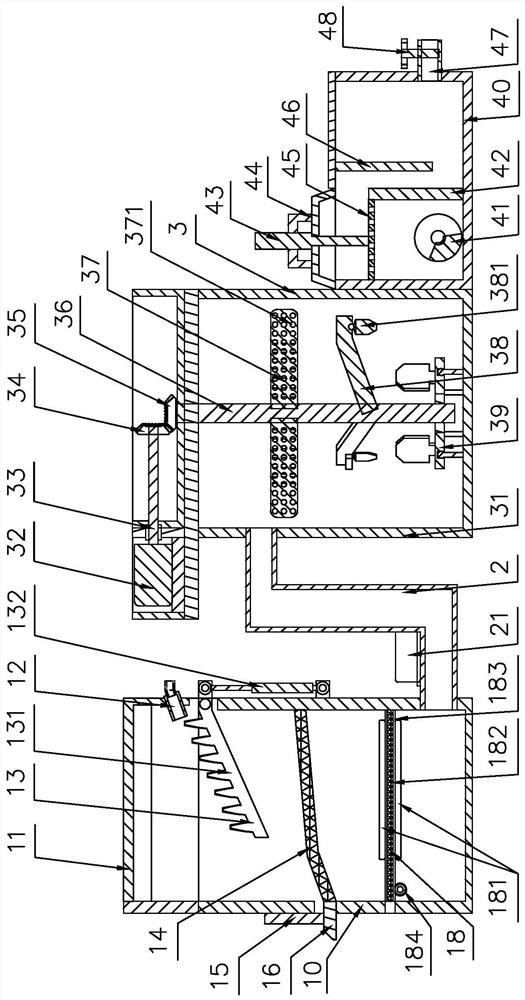

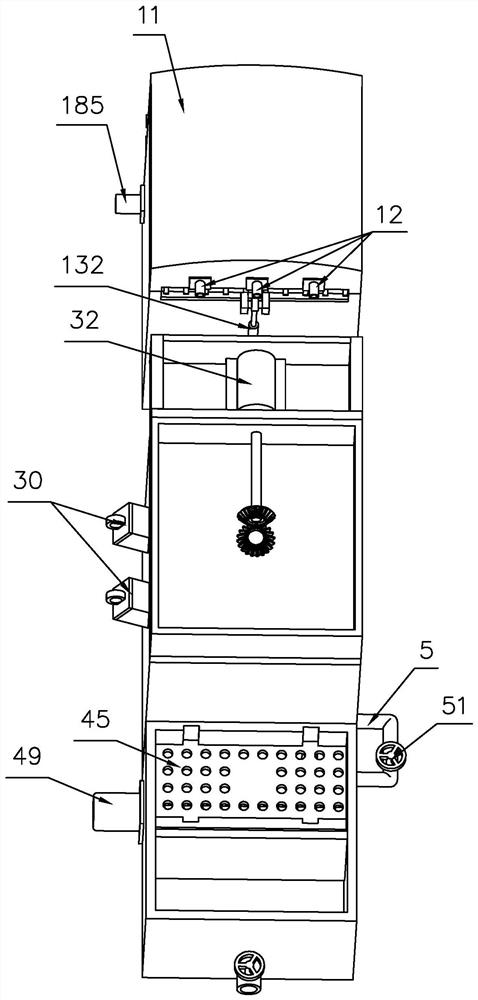

[0026] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-6 , to further specifically describe the technical solution of the present invention.

[0027] A wastewater treatment device for building construction, comprising a sediment treatment mechanism 1, a water flow channel 2, a water pump 21, a flocculation stirring mechanism 3, a sewage purification mechanism 4, a connecting pipeline 5, and a valve II 51. The sediment treatment mechanism 1 One side is provided with a water flow channel 2, and one side of the water flow channel 2 is provided with a water pump 21, and the other side of the water flow channel 2 is provided with a flocculation stirring mechanism 3, and one side of the flocculation stirring mechanism 3 is provided with a sewage discharge purification mechanism 4, and the flocculation A connecting pipeline 5 is provided between the stirring mechanism 3 and the sewage purification mechanism 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com