Anti-rutting anti-fatigue high-modulus composite modified asphalt and preparation method thereof

A composite modified asphalt, anti-fatigue technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of insufficient rutting resistance and elastic deformation ability of asphalt, and achieve a good price advantage, simple production process, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

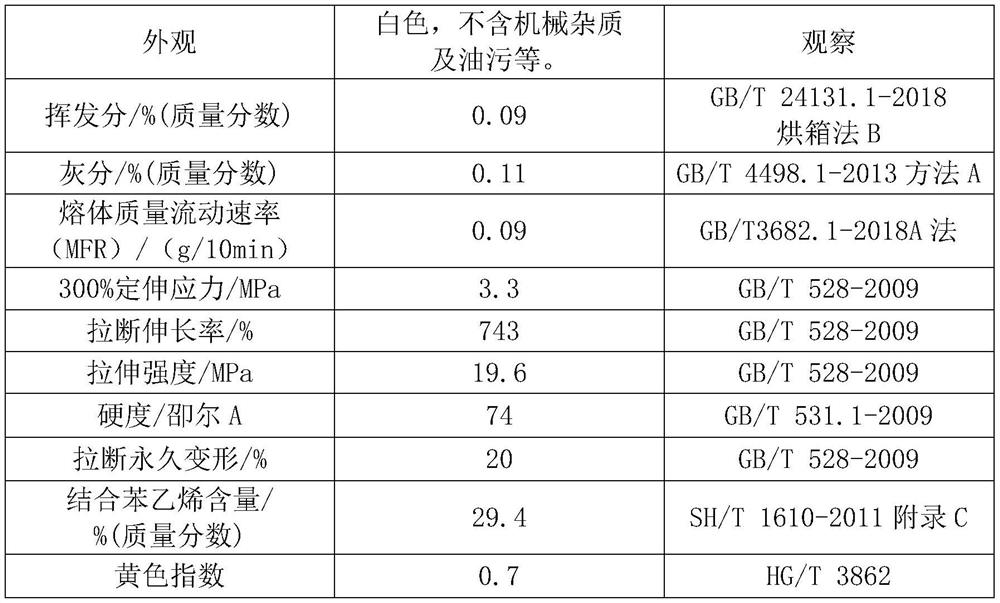

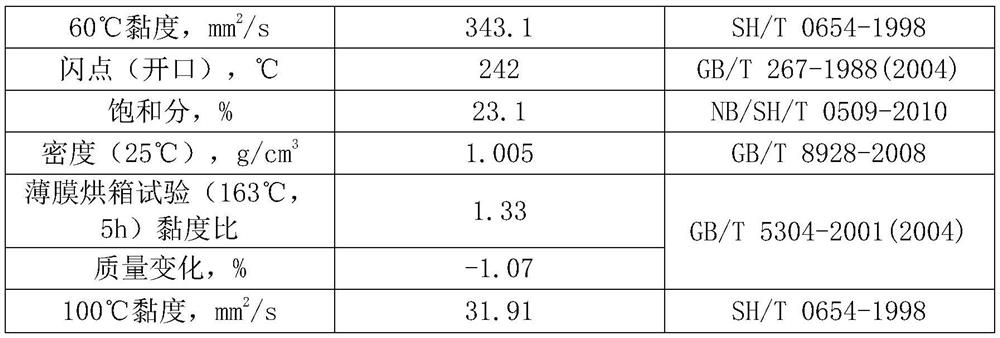

[0035] A kind of anti-rutting and anti-fatigue high modulus composite modified asphalt, its ingredients are calculated by weight: 100 parts of domestic Zhenhai No. 90 base asphalt, 4 parts of SBS, 9 parts of composite natural rock asphalt, 3 parts of additives, and 0.3 parts of stabilizer ;

[0036] Preferably, the preparation steps are as follows:

[0037] (1) Heat the base asphalt to 140 °C, slowly put a certain proportion of additives and SBS into the container, stir and heat up, and keep it at about 180 °C for 20 minutes at high speed (shear speed 45000 rpm, temperature during shearing will rise, must ensure that the temperature is not higher than 180 ℃), to obtain SBS modified asphalt;

[0038] (2) After the shearing is stopped, the sample is put into a constant temperature heating mantle to keep the temperature at 180°C and continue mechanical stirring, slowly add a certain proportion of stabilizer and composite natural rock asphalt powder, and continue stirring for 3 h...

Embodiment 2

[0041] A kind of anti-rutting and anti-fatigue high modulus composite modified asphalt, its ingredients are calculated by weight: 100 parts of domestic Zhenhai No. 90 base asphalt, 4 parts of SBS, 10 parts of composite natural rock asphalt, 3 parts of additives, and 0.3 parts of stabilizer ;

[0042] Preferably, the preparation steps are as follows:

[0043] (1) Heat the base asphalt to 140 °C, slowly put a certain proportion of additives and SBS into the container, stir and heat up, and keep it at about 180 °C for 20 minutes at high speed (shear speed 45000 rpm, temperature during shearing will rise, must ensure that the temperature is not higher than 180 ℃), to obtain SBS modified asphalt;

[0044] (2) After the shearing is stopped, the sample is put into a constant temperature heating mantle to keep the temperature at 180°C and continue mechanical stirring, slowly add a certain proportion of stabilizer and composite natural rock asphalt powder, and continue stirring for 3 ...

Embodiment 3

[0047] A kind of anti-rutting and anti-fatigue high modulus composite modified asphalt, its ingredients are calculated by weight: 100 parts of domestic Zhenhai No. 90 base asphalt, 4 parts of SBS, 11 parts of composite natural rock asphalt, 3 parts of additives, and 0.3 parts of stabilizer ;

[0048] Preferably, the preparation steps are as follows:

[0049] (1) Heat the base asphalt to 140 °C, slowly put a certain proportion of additives and SBS into the container, stir and heat up, and keep it at about 180 °C for 20 minutes at high speed (shear speed 45000 rpm, temperature during shearing will rise, must ensure that the temperature is not higher than 180 ℃), to obtain SBS modified asphalt;

[0050](2) After stopping shearing, put the sample into a constant temperature heating jacket to keep the temperature at 180°C and continue to stir mechanically, slowly add a certain proportion of stabilizer and composite natural rock asphalt powder, and continue stirring for 3 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com