Hydrotreatment method for lubricant base oil

A lubricating oil base oil, hydrotreating technology, applied in hydrotreating process, treating hydrocarbon oil, lubricating composition, etc.

Active Publication Date: 2021-09-24

PETROCHINA CO LTD

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these improvements are not sufficient to meet refiners' increasingly stringent fuel requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

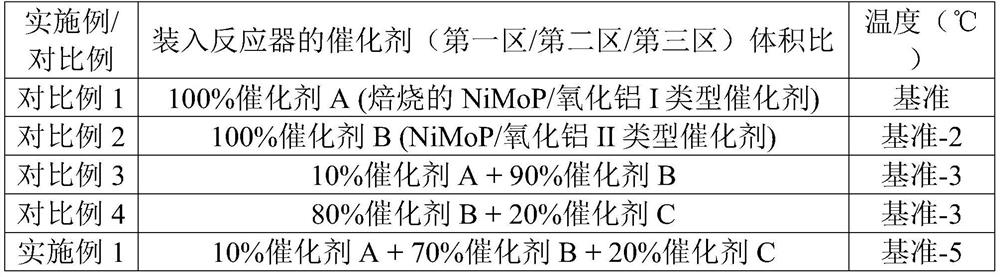

[0064] Using the catalyst prepared by the above method, the first zone is equipped with calcined NiMoP / alumina type I catalyst (catalyst A: 10% by volume), and then the second zone is equipped with II type catalyst containing organic promoter (catalyst B: 70% of the volume). The third zone is then loaded with a support based on a silicon-modified NiMo catalyst rich in type II active phase (catalyst C: 20% by volume).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a hydrotreating method for lubricant base oil. The method relates to a direct grading combination of three different catalysts, namely a conventional roasted type I catalyst, a type II catalyst containing an organic auxiliary agent, and a type II catalyst which has a barrier based on silicon modification and is rich in active phases. Lubricating oil base oil feed firstly flows through the type I catalyst, then effluent is in contact with the type II catalyst containing the organic auxiliary agent, and finally the effluent is in contact with the type II catalyst which has a barrier based on silicon modification and is rich in active phases, so that the purpose of deeply removing sulfur and nitrogen impurities is achieved, and meanwhile, the stability of the catalyst is improved.

Description

technical field [0001] The invention relates to a hydrotreating method for lubricating oil base oil, in particular to a hydrotreating method suitable for raw materials of high nitrogen lubricating oil base oil. Background technique [0002] At present, the domestic market has increasingly stringent quality requirements for lubricating base oils. Isomerization dewaxing technology is the most effective means to realize the production of high-quality lube base oil, and this process is usually realized by hydroprefining-isomerization dewaxing-supplementary refining. When producing lubricating oil base oil through isomerization dewaxing process, one of the key ways to improve the quality of base oil is to select a hydrotreating catalyst with high-efficiency desulfurization, denitrogenation and aromatic hydrocarbon saturation functions to provide more high-quality raw materials (sulfur Nitrogen qualified, high viscosity index). The feed to the isomerization section requires a ni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G65/02B01J27/19B01J31/34C10M177/00

CPCC10G65/02B01J27/19B01J31/34C10M177/00C10G2300/202B01J2231/641B01J2231/646

Inventor 王延飞余颖龙王燕张雅琳谢彬王嘉祎王晶晶赵梓贺袁晓亮张占全付凯妹庄梦琪

Owner PETROCHINA CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com