Steam turbine primary steam extraction external connection industrial steam supply equipment

An industrial steam and steam turbine technology, applied in mechanical equipment, steam application, steam engine equipment, etc., can solve the problems of normal production of tire companies, high cost of boiler new steam, and untimely adjustment, so as to avoid sudden changes in boiler load and realize The effect of stable supply and simple modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

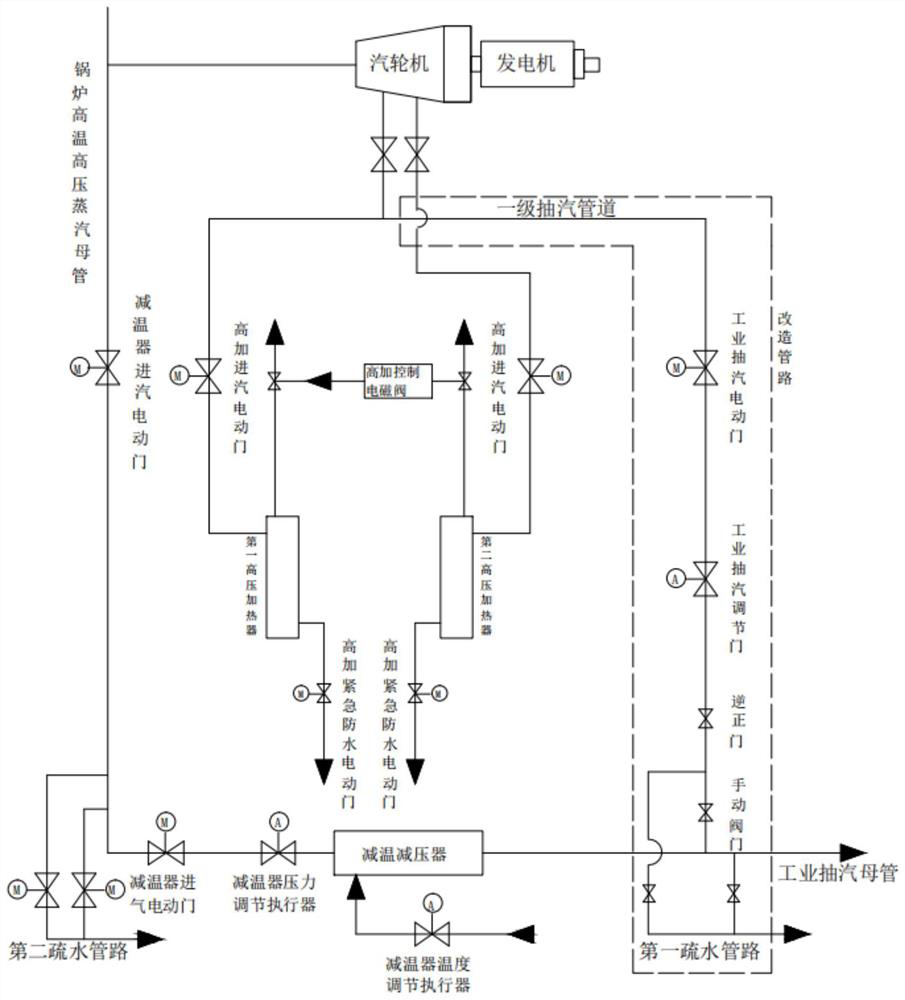

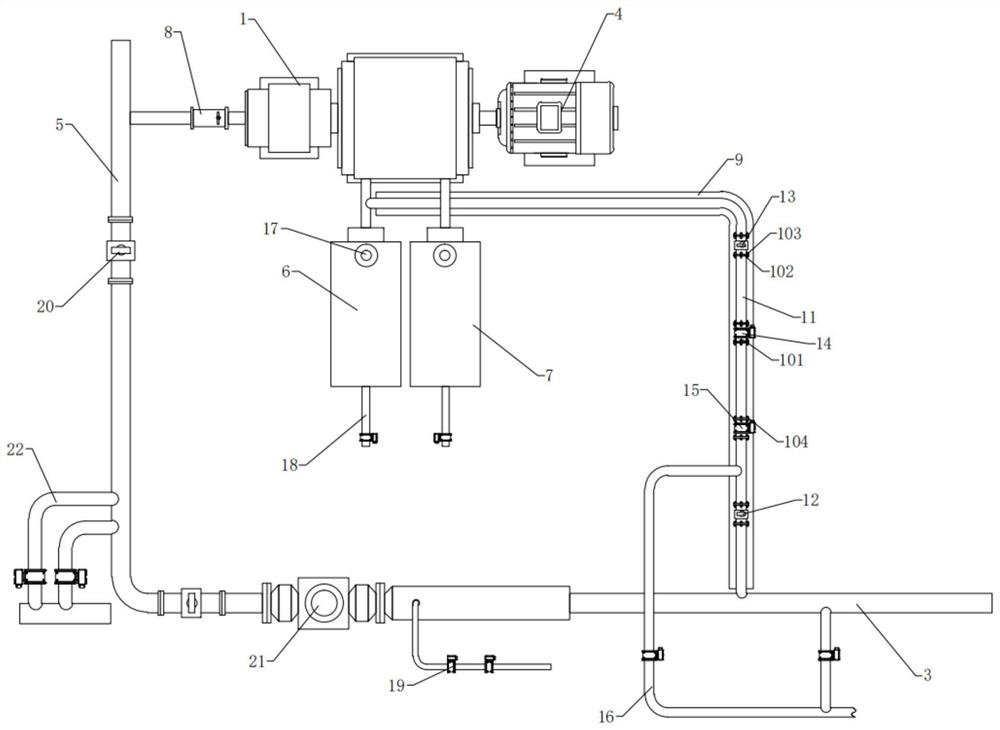

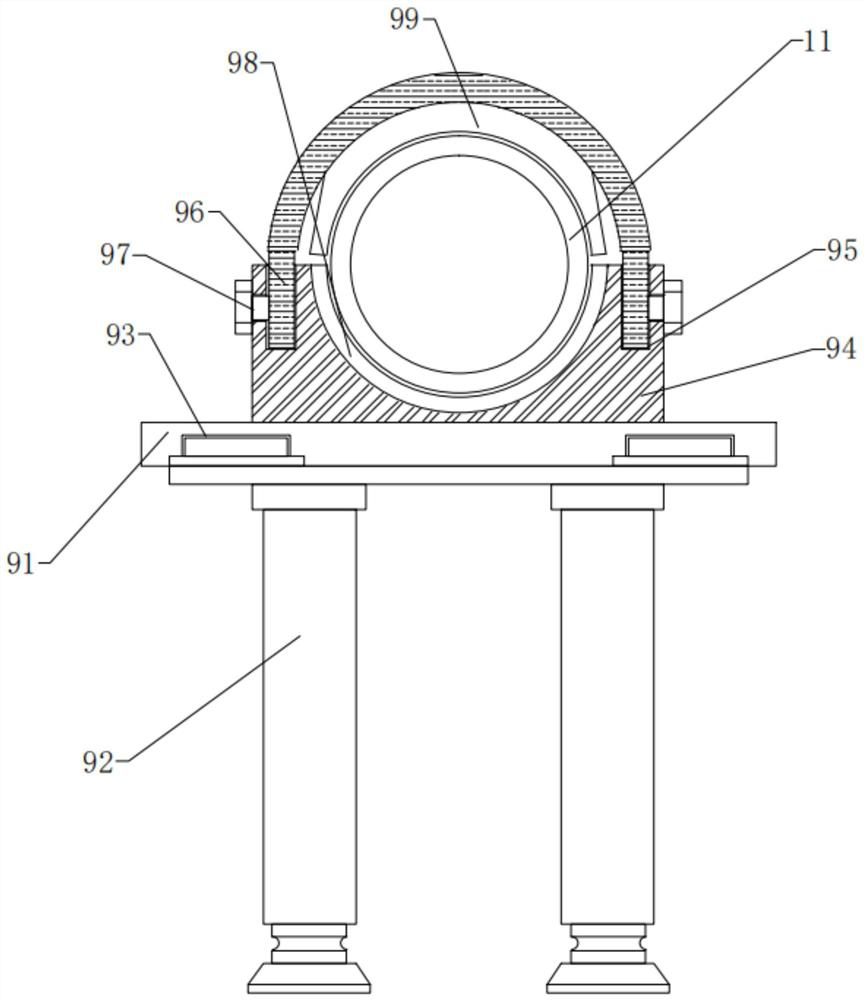

[0028] Embodiment: according to specification Figure 1-5 It can be seen that this case is a steam turbine 1 first-stage steam extraction connected to an external supply of industrial steam equipment, including steam turbine 1, desuperheater 2, industrial extraction steam main pipe 3, generator 4, boiler high-temperature and high-pressure steam main pipe 5, the first A high-pressure heater 6 and a second high-pressure heater 7, their connection relationship and positional relationship are as follows;

[0029] The steam turbine 1 communicates with the high-temperature and high-pressure steam main pipe 5 of the boiler, and is connected with the first high-pressure heater 6 and the second high-pressure heater 7, the generator 4 is connected with the rotor of the steam turbine 1, and the temperature and pressure reducer 2 is connected with the high-temperature and high-pressure boiler The end of the steam main pipe 5, the desuperheater 2 is externally connected to the industrial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com