Fuel cell humidification system

A humidification system, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problem of reducing the volume power density and mass power density of the system, increasing the bypass passage or adjusting the temperature before and after the humidifier, increasing the complexity of the system and Control difficulty and other issues to achieve the effects of controllable humidification capacity, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

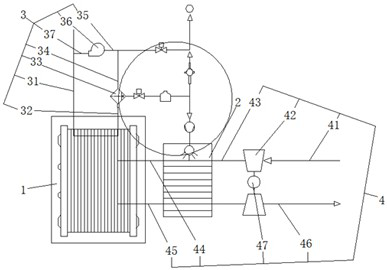

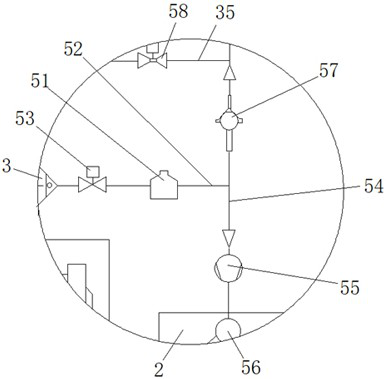

[0032] Examples, see Figure 1-2 , a fuel cell humidification system, comprising an electric stack 1 and an air-to-air cooler 2, the electric stack 1 is connected to a circulating hydrogen intake assembly 3 by pipes;

[0033] Both sides of the air-to-air cooler 2 are detachably connected to the mobile air transmission assembly 4, and the middle part of the mobile air transmission assembly 4 is detachably connected to the electric stack 1;

[0034] A circulating water assembly 5 is provided between the air-to-air cooler 2 and the electric stack 1 , and one end of the circulating water assembly 5 is detachably connected to the circulating hydrogen intake assembly 3 .

[0035] see figure 1 , the circulating hydrogen intake assembly 3 includes a first intake pipe 31, the first intake pipe 31 is detachably connected to the electric stack 1, one side of the electric stack 1 is detachably connected to a first connecting pipe 32, the first A connecting pipe 32 is a detachable water ...

Embodiment 2

[0039] Embodiment 2, a fuel cell humidification system, including the following control steps:

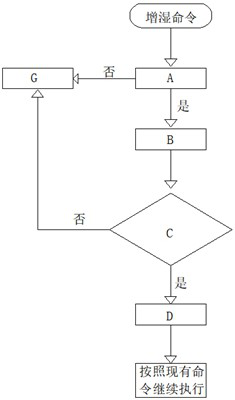

[0040] Step S1: Humidification command;

[0041]Step A: Detect or calculate the target current point humidity A1, if the humidity is less than the target value SETA, output to B when yes, and output to G when no;

[0042] Step B: Calculate the water pump speed b according to the humidification amount A1, and then go to C after obtaining the value;

[0043] Step C: Execute the speed of the water pump calculated in step B to perform humidification;

[0044] Step D: Real-time detection or calculation of the target current point humidity A2, whether the humidity is less than the target value SETA;

[0045] Step E: When the humidity obtained in step D is less than the target value SETA, output to E, calculate the pump speed b2 according to the humidification amount A3, and finally continue to execute according to the existing command;

[0046] Step G: When the values calculated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com