Ultrathin heat dissipation device and heat dissipation method

A heat dissipation device and ultra-thin technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0026] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

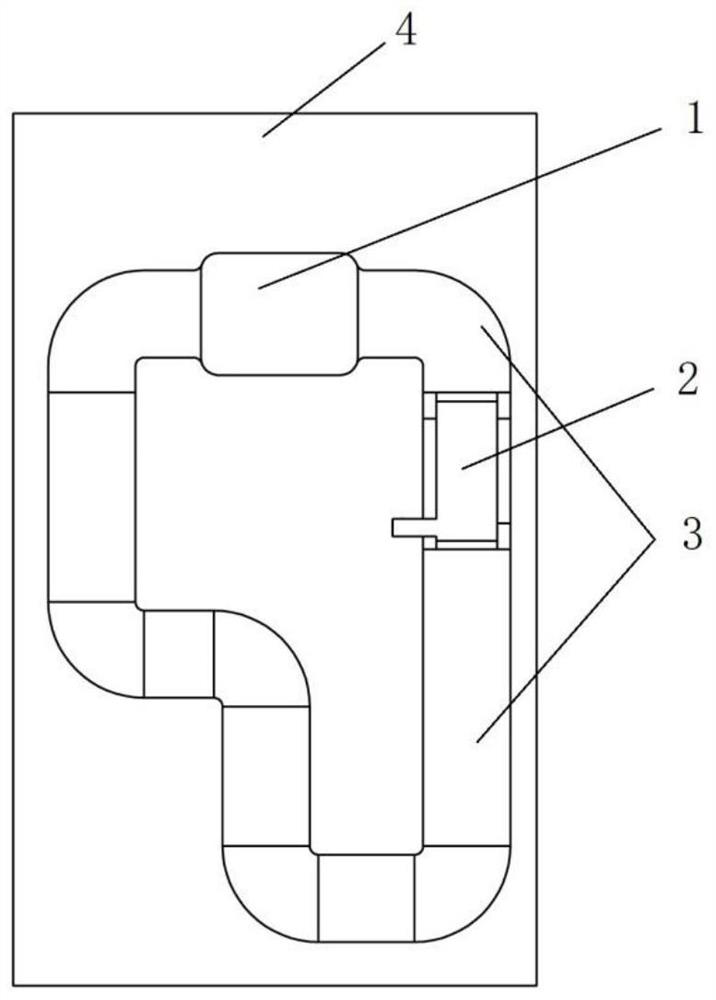

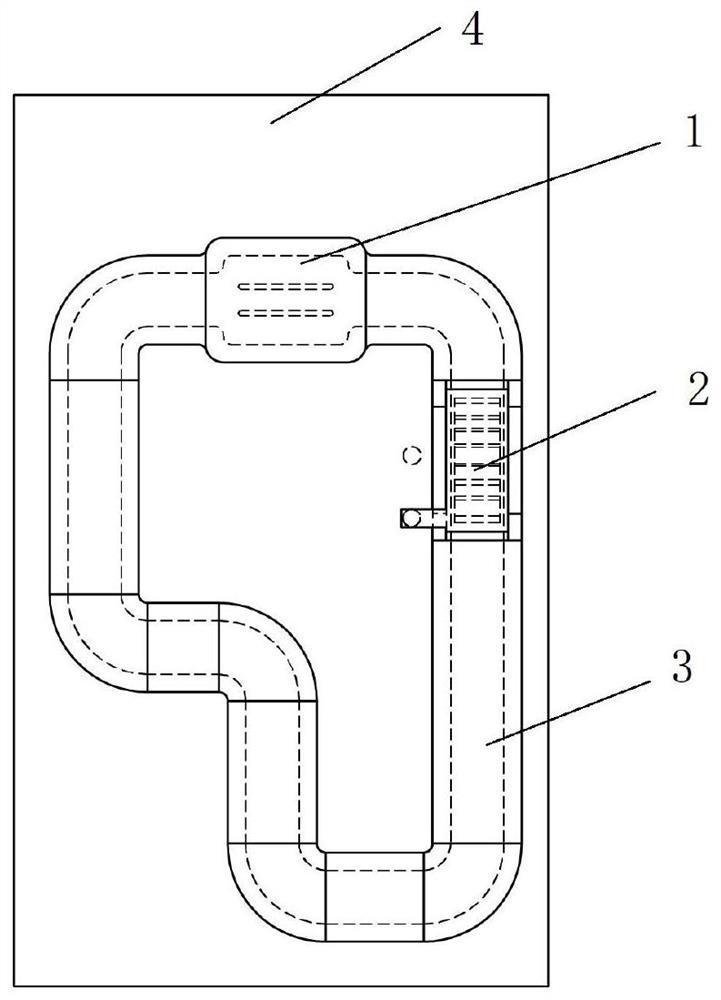

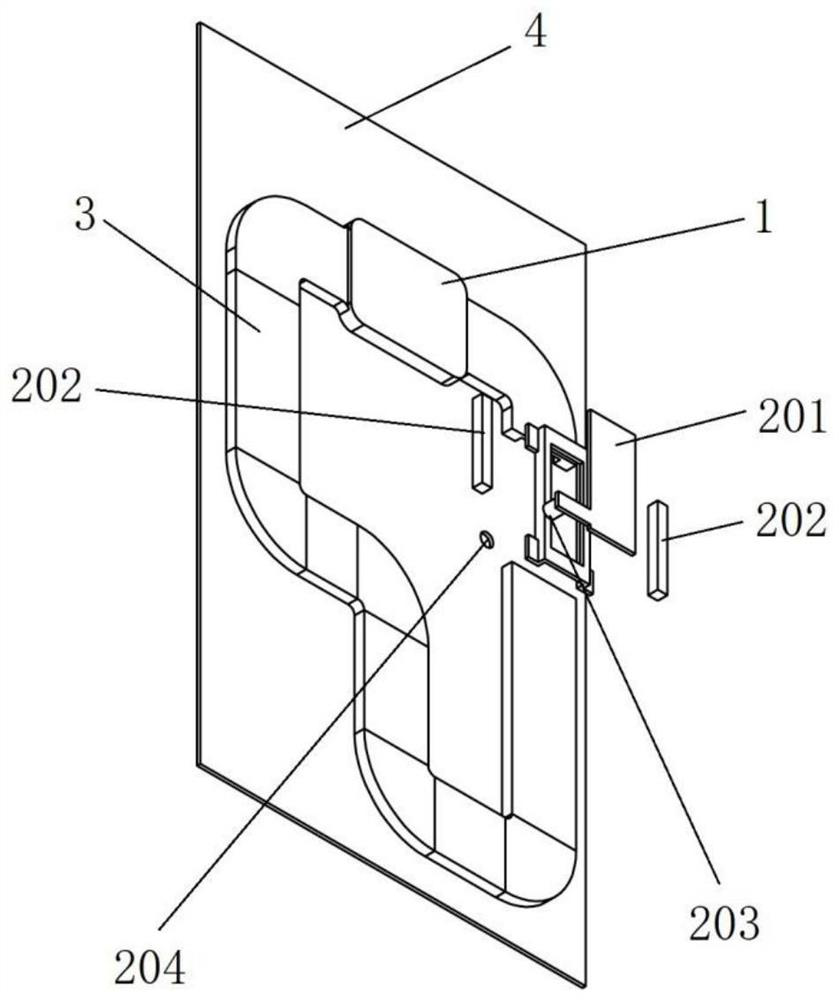

[0027] Such as Figure 1 to Figure 5 As shown, an ultra-thin heat dissipation device includes a heat collector 1 and an electromagnetic pump 2, and the heat collector 1 and the electromagnetic pump 2 are connected end to end through a heat dissipation flow channel 3 to form a closed loop. Specifically, the heat collector 1 is made of copper and has a liquid metal flow channel inside. The size of the internal flow channel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com