A bb cream containing non-ionic silicon-containing modified aqueous polyurethane dispersion

A water-based polyurethane, non-ionic technology, applied in the field of personal care, can solve the problems of inability to satisfy concealer, moisturizing, long-lasting makeup, skin feel, easy makeup removal, difficulty in adjusting formula, insufficient rigidity, etc. And smooth, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

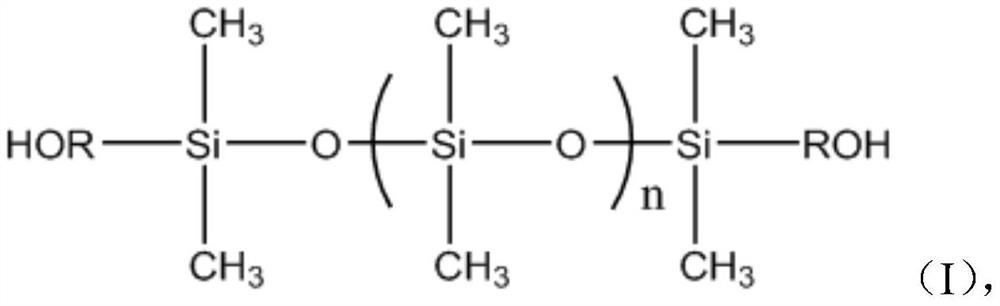

[0116] Example 1: Non-ionic silicon-containing modified aqueous polyurethane dispersion

[0117] 48 grams of PPG1000, 9 grams of CHDM, 67 grams of N120, and 32 grams of KF6001 were added to a four-necked flask with a condenser and agitator, followed by 80 grams of HMDI, 0.05 grams of organic bismuth 8108, and 26.6 grams of acetone. ℃ reaction for 1.5 hours, NCO value is 3.59%;

[0118] After cooling to 20℃, add 266 grams of acetone and 80 grams of DX1704;

[0119] Add 726 grams of water under high-speed (1400 rev / min) shear dispersion, and stir for 5 minutes to obtain a coarse emulsion; then add a mixed solution of 3.2 grams of EDA and 13 grams of deionized water, stir for 10 minutes, and the reaction temperature is 35 ° C;

[0120] Then, the crude emulsion was removed from the solvent acetone at 45°C and 0.01MPa vacuum to obtain an aqueous polyurethane emulsion with a particle size (mean particle size) d=40 nm and a solid content of 30 wt%, referred to as silicon-modified poly...

Embodiment 2

[0121] Example 2: Non-ionic silicon-containing modified aqueous polyurethane dispersion

[0122] 58 grams of PPG2000, 45 grams of CHDM, 159 grams of N120, and 138 grams of KF6002 were added to a four-necked flask with a condenser and agitator, followed by 167 grams of IPDI, 0.07 grams of organic bismuth 8108, and 38.6 grams of acetone. ℃ reaction for 1.5 hours, NCO value is 2.95%;

[0123] After cooling to 20°C, add 243 grams of acetone and 115 grams of DX1708;

[0124] Add 1536 grams of water under high-speed (1500 rev / min) shear dispersion, stir for 5 minutes to obtain a coarse emulsion, then add a mixed solution of 8 grams of EDA and 40 grams of deionized water, continue stirring for 10 minutes, and the reaction temperature is 40 ° C;

[0125] The crude emulsion was removed from the solvent acetone under vacuum conditions of 45°C and 0.01MPa to obtain a water-based polyurethane emulsion with a particle size (referring to the average particle size) d=60nm and a solid conten...

Embodiment 3

[0126] Example 3: Non-ionic silicon-containing modified aqueous polyurethane dispersion

[0127] Add 1 g of PPG1000, 39.1 g of CHDM, 2 g of 1,4-butanedithiol, 109 g of N120, 90 g of KF6001 into a four-necked flask with a condenser and a stirrer, and then add 141 g of IPDI, 0.07 g grams of organic bismuth 8108, 38.6 grams of acetone, react at 75 ° C for 1.5 hours, the NCO value is 3.79%;

[0128] After cooling to 20°C, add 386 grams of acetone and 140 grams of sicare 2422;

[0129] Add 1186 grams of water under shear dispersion at 1500 rpm, stir for 5 minutes to obtain a coarse emulsion, then add a mixed solution of 8 grams of EDA and 40 grams of deionized water, continue stirring for 10 minutes, and the reaction temperature is 40 ° C;

[0130] The crude emulsion was removed from the solvent acetone under vacuum conditions of 45°C and 0.01MPa to obtain an aqueous polyurethane emulsion with an average particle size of d=60nm and a solid content of 30wt%, silicon-modified polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com