Radiator extrusion die

A technology of extrusion die and radiator, applied in the direction of metal extrusion die, etc., can solve the problem of radiator type radiator cracking and other problems, and achieve the effect of avoiding cracking and water leakage, reasonable mold structure design and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

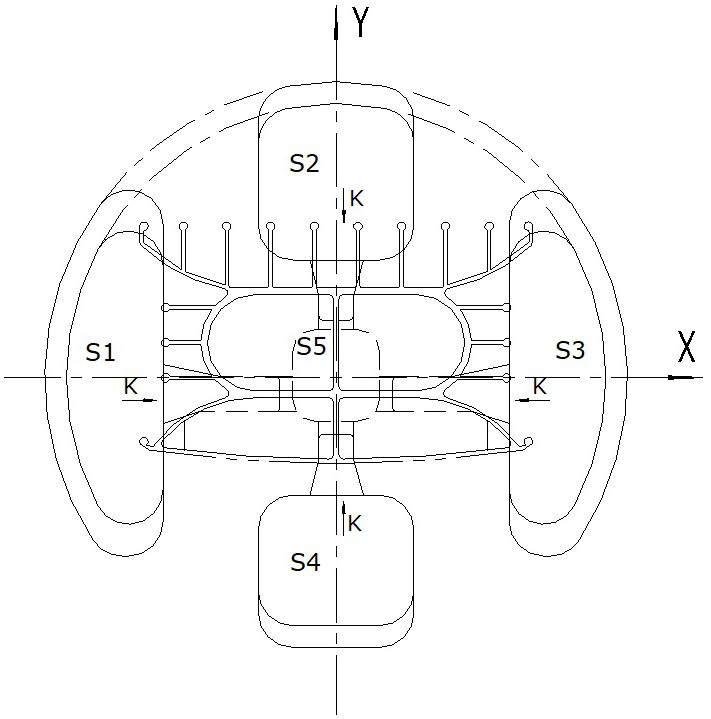

[0032] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

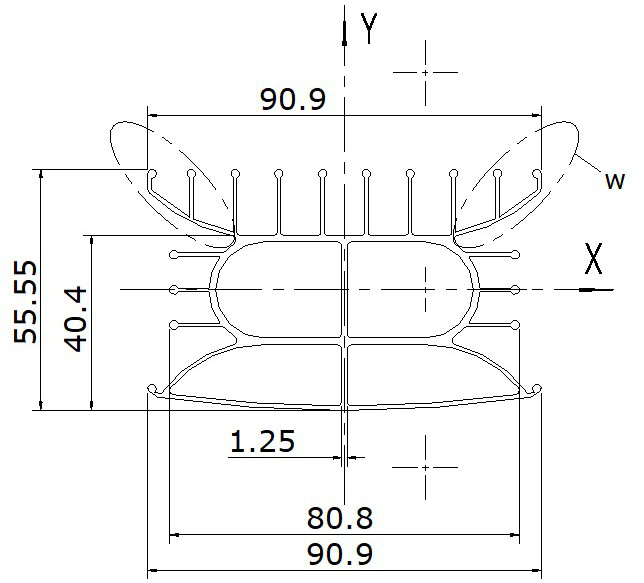

[0033] still with figure 1 Take the most widely used radiator aluminum profile product in the market as an example. For the production of this hot-extruded aluminum profile product, the traditional radiator aluminum profile extrusion die has a mold structure The overall design is not reasonable enough, mainly reflected in the following three aspects:

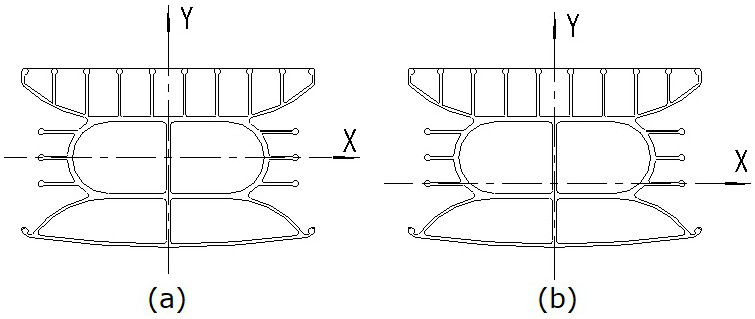

[0034] 1. The design of the split hole of the upper die is unreasonable. At present, the enterprises adopt the "X" shape split bridge layout, and all adopt the conventional four split hole design, which leads to the metal in the center of the four cavities intersecting in the extrusion process. It is difficult to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com