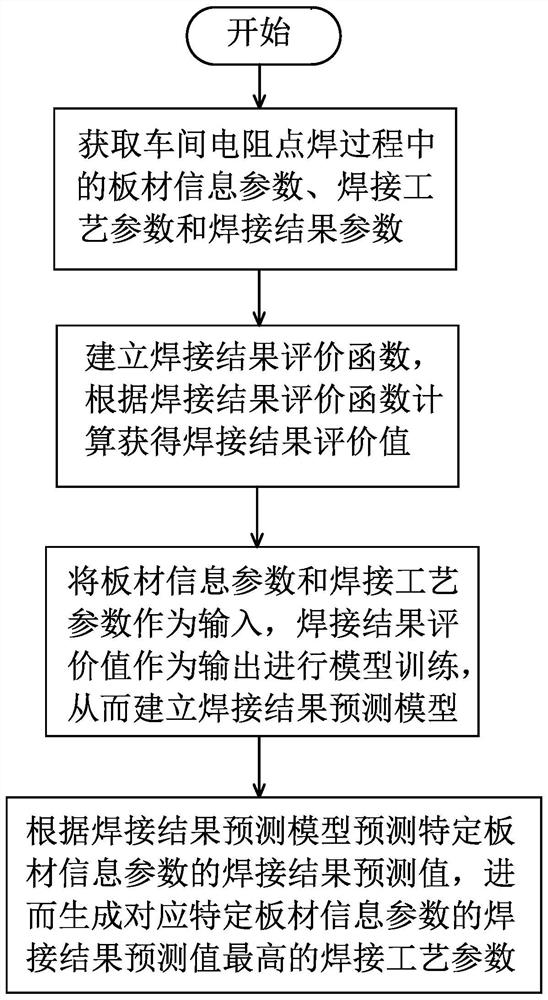

Resistance spot welding process parameter automatic generation method and system

A resistance spot welding and automatic generation technology, applied in resistance welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as the impact of vehicle safety performance, the inability to guarantee the welding quality of welding spots, etc., to improve welding quality and efficiency, and facilitate operation. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

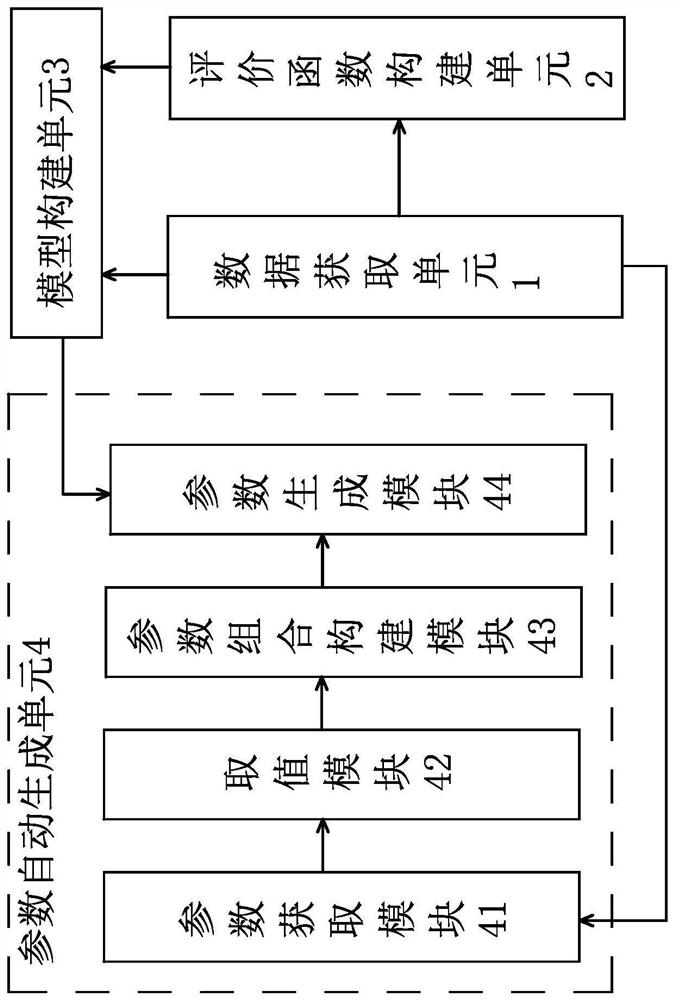

[0060] Such as image 3 As shown, the automatic generation system of the resistance spot welding process parameters includes: a data acquisition unit 1, the data acquisition unit 1 communicates with the data server in the resistance spot welding workshop through the Internet of Things, and is used to obtain the plate information parameters stored in the data server, Welding process parameters and welding result parameters;

[0061] The evaluation function construction unit 2 is used to establish the welding result evaluation function according to the welding result parameters; specifically, the welding result evaluation function is constructed by the following calculation formula;

[0062]

[0063] Among them, F is the welding result evaluation value; UIP is the quality factor; f is the spatter value; PSF is the process stability factor;

[0064] The model building unit 3 is used to use the plate information parameters and welding process parameters as input, and use the w...

Embodiment 2

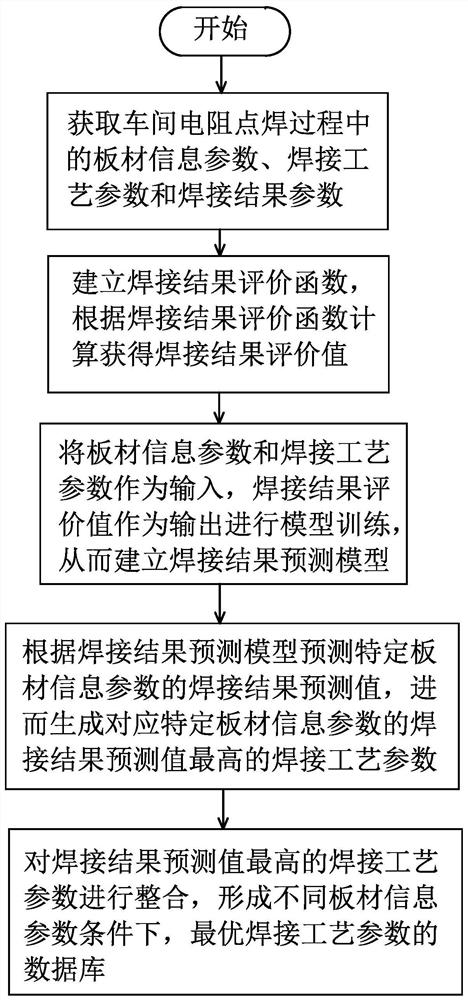

[0087] Such as figure 2 As shown, the technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that the welding result prediction value of the specific plate information parameter is predicted according to the welding result prediction model, and then the corresponding specific plate information parameter is generated. After the welding process parameters with the highest welding result prediction value, it also includes:

[0088] The welding process parameters with the highest welding result prediction value are integrated to form a database of optimal welding process parameters under different plate information parameters. The establishment of the database can directly obtain the optimal welding process parameters according to the plate information parameters in the later use. The itinerary of the database can also be used as the initial setting value of the welding process parameters when the welding commissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com