Water surface floating garbage cleaning equipment

A technology for garbage cleaning and water surface floating, which is applied in the direction of open water surface cleaning, passenger handling equipment, cargo handling equipment, etc. Improve performance, clean up quickly and easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

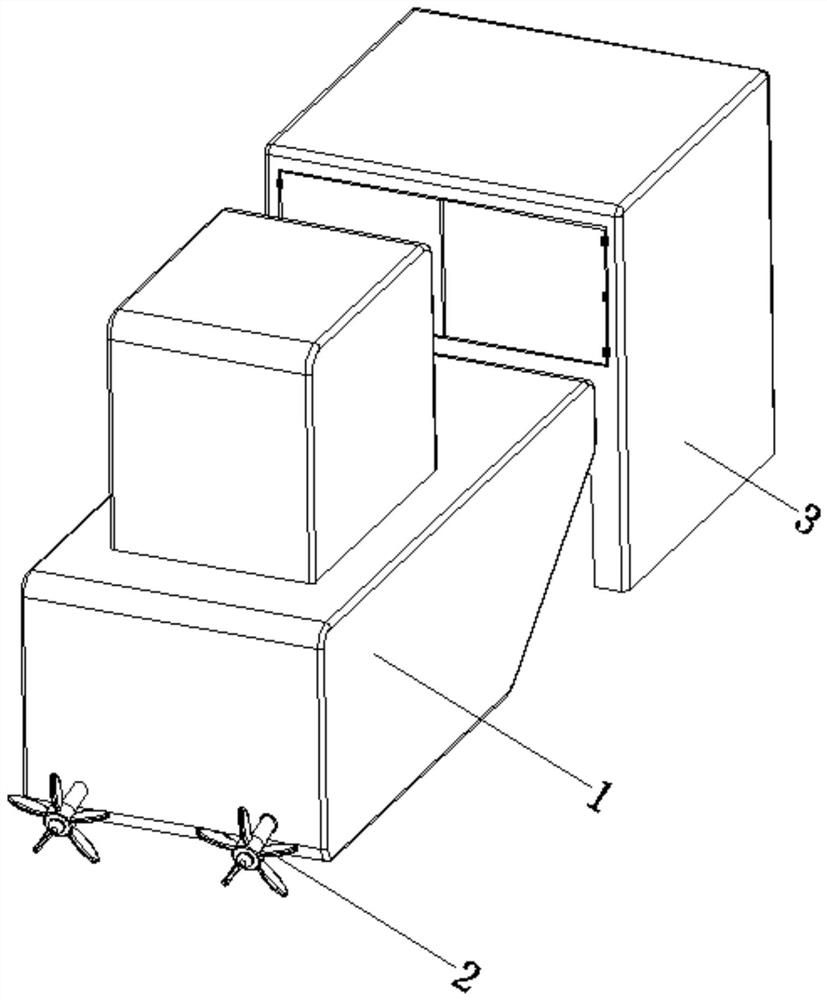

[0032] see Figure 1-7 , the present invention provides a technical solution: a device for cleaning floating garbage on the water surface, including a hull 1, a propeller 2, and a garbage cleaning device 3. The device 3 is arranged on the end of the hull 1 away from the propeller 2;

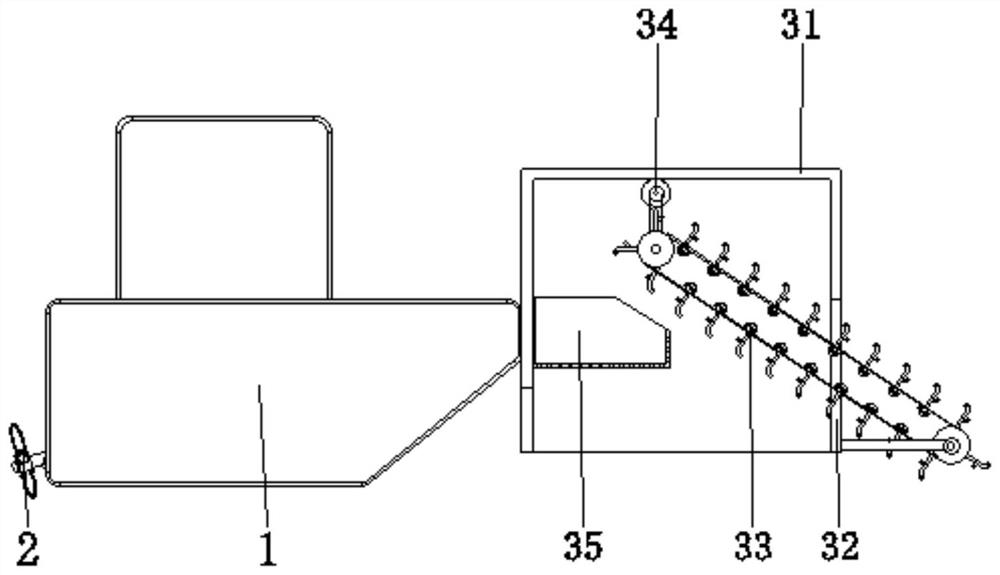

[0033] Garbage salvage device Garbage cleaning device 3 is provided with shell 31, breach 32, rubbish salvage device 33, power mechanism 34, storage barrel 35, and the surface side of rubbish salvage device shell 31 is fixedly connected with the end of hull 1, and the garbage salvage device breach 32 is provided on both sides corresponding to the bottom of the surface of the shell 31. The garbage salvage device 33 is arranged in the inside of the shell 31 and is positioned at the position of the gap 32. One end of the device 33 is mated and connected, and one side of the surface of the storage barrel 35 of the garbage salvage device is fixedly connected to one side of the inner wall of the housi...

Embodiment example 2

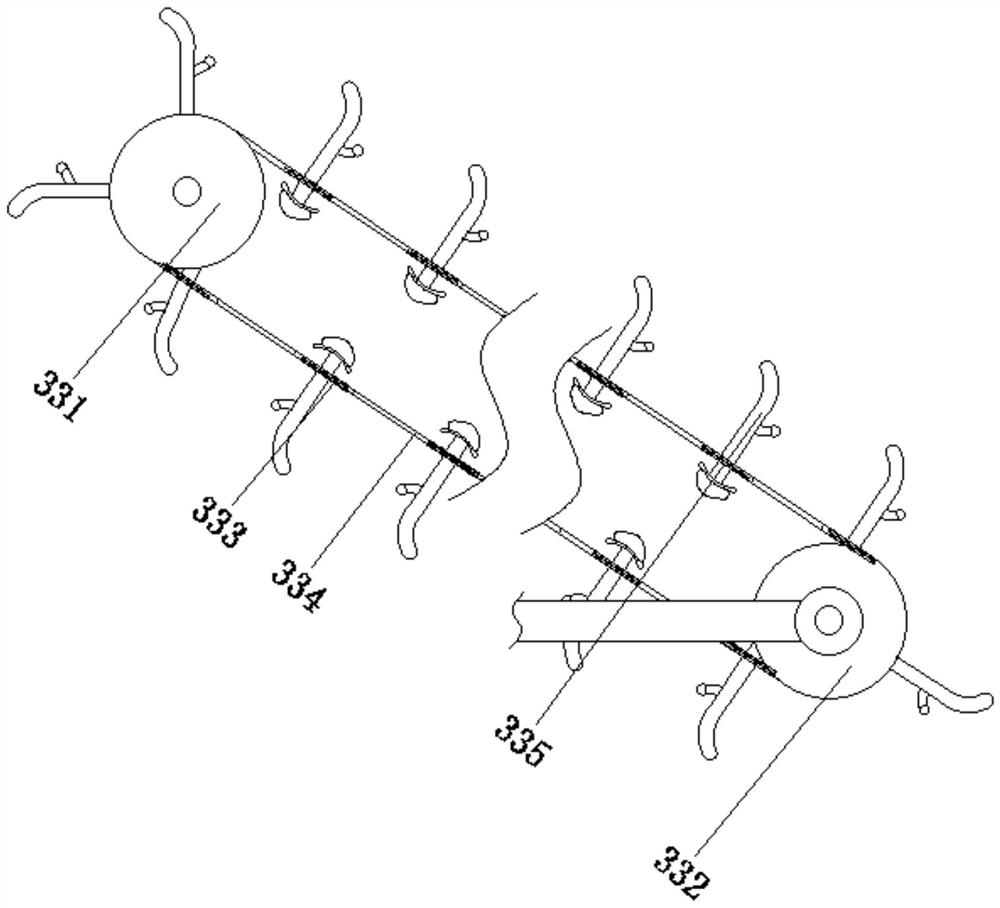

[0035]The garbage salvage device 33 is provided with a driving roller device 331, a driven roller 332, a conveyor belt 333, a slot 334, and a gear shifting device 335. The garbage salvaging device driving roller device 331 is rotatably connected between the two sides corresponding to the inner wall of the housing 31, The garbage salvage device driven roller 332 is rotatably connected to the surface bottom of the casing 31 and is close to the position of the gap 32, the garbage salvage device conveyor belt 333 is arranged on the surface of the driving roller device 331 and the driven roller 332, and the garbage salvage device slot 334 is provided in the On the surface of the conveyor belt 333, the gear shifting device 335 of the garbage salvage device is fixed on the surface of the conveyor belt 333 and close to the position of the slot 334, and the driving roller device 331 is driven by the power mechanism 34, so that the conveyor belt 333 drives the gear shifting device 335 to ...

Embodiment example 3

[0037] The driving roller device 331 is provided with a roller body 3311, a groove 3312, and a pressing device 3313. The end of the garbage salvage device roller body 3311 is rotationally connected with the inner wall of the housing 31, and the garbage salvage device groove 3312 is provided on the surface of the roller body 3311. The rubbish salvage device pressing device 3313 is arranged inside the roller body 3311 and is located at the position of the groove 3312. When the driving roller device 331 is driven by the conveyor belt 333 to move continuously, it can timely salvage the floating garbage on the water surface, and at the same time the driving roller device When 331 moves to the position of the driving roller device 331, the end of the driving roller device 331 is in the groove 3312, and presses the pressing device 3313 to promote the dumping of the salvaged garbage and reduce the situation of sticking due to the water film .

[0038] The pressing device 3313 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com