Integrated belt conveyor tail device for mining

A belt conveyor, an integrated technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of single function, large inclination angle, time-consuming and labor-intensive problems of belt conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions and technical effects of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

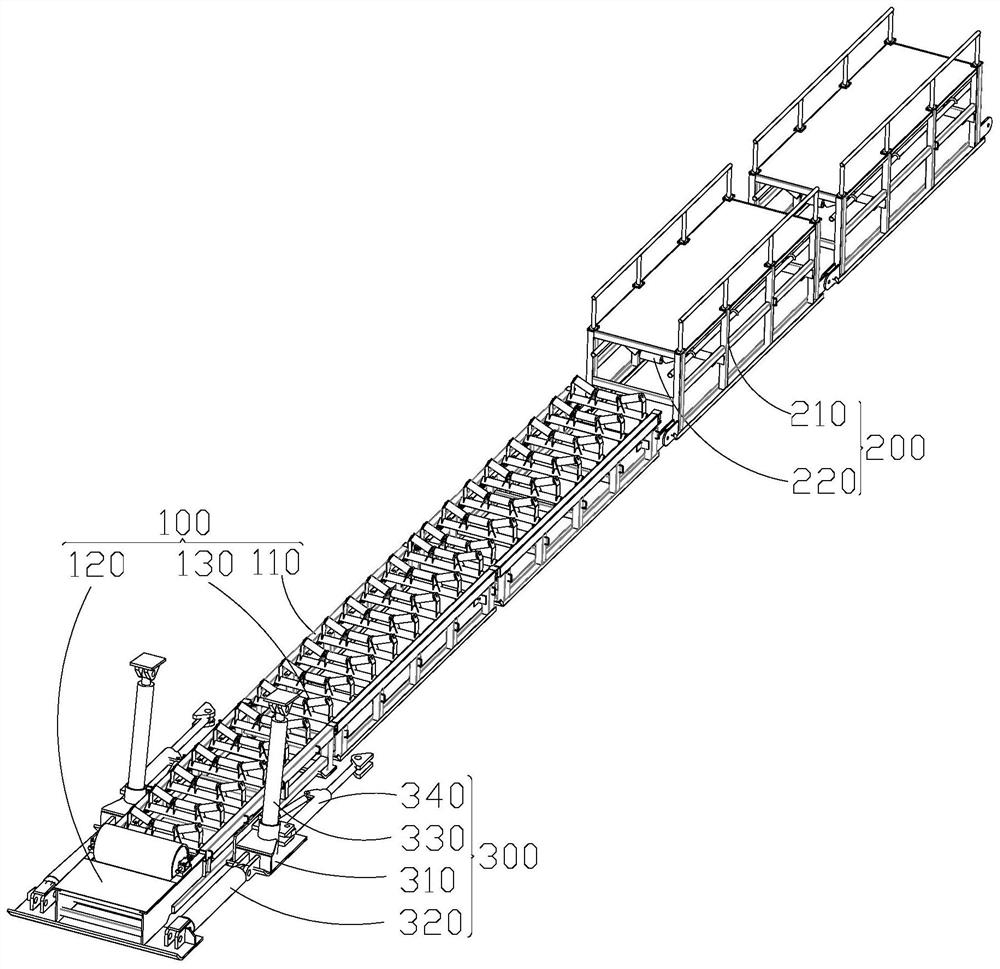

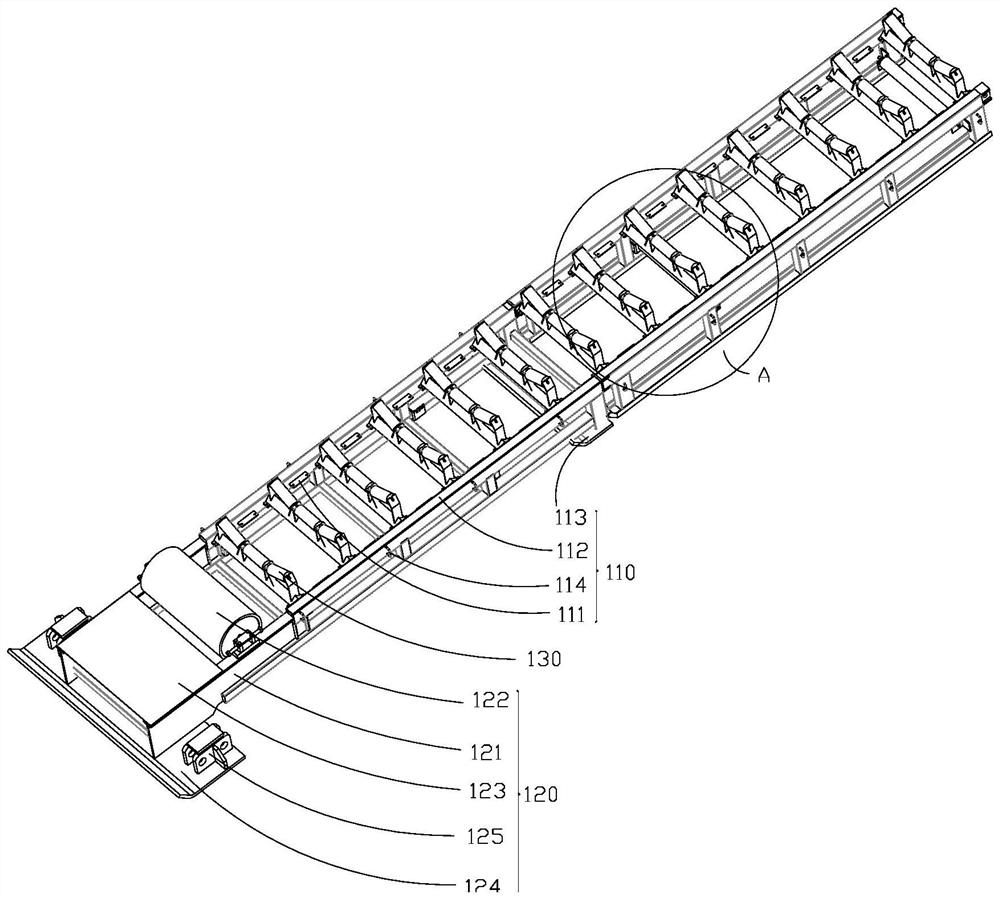

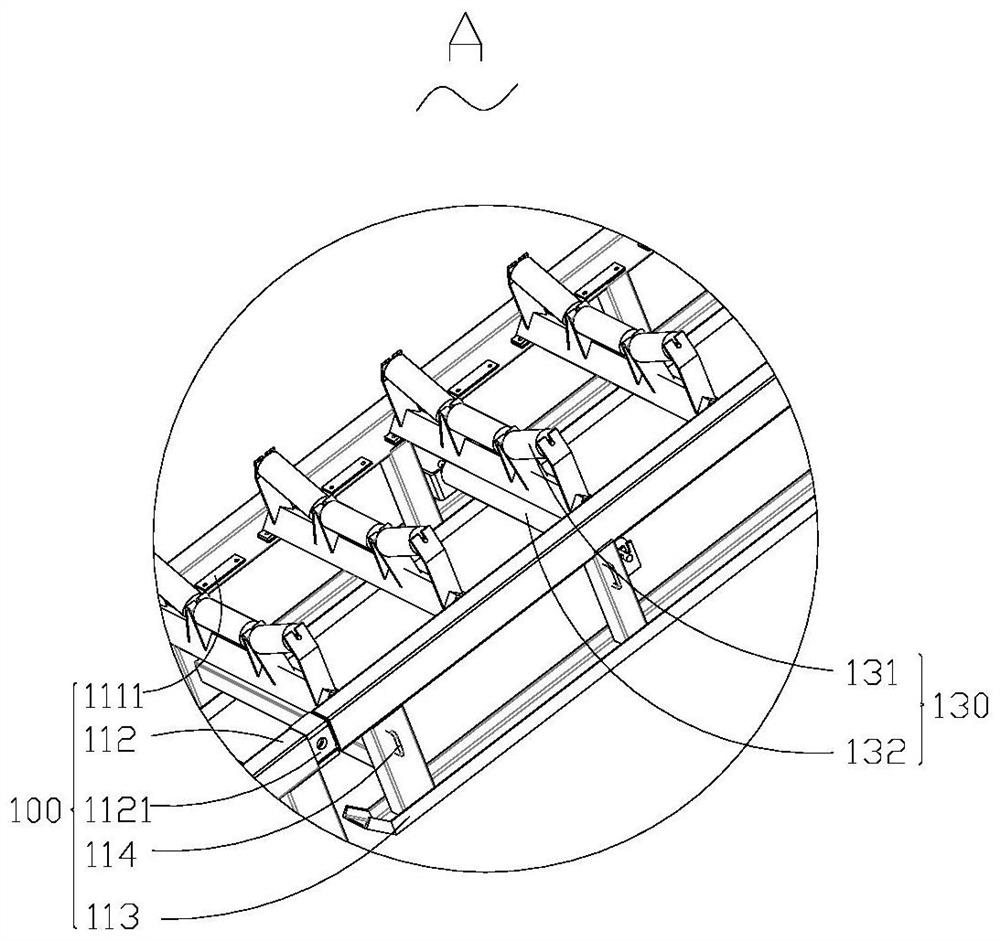

[0028] see figure 1 , an integrated belt conveyor tail device for mining, including a walking frame body 100, a conveying frame assembly 200, and a walking and supporting assembly 300, the walking frame body 100 and the conveying frame assembly 200 are detachably connected, the The walking and supporting assembly 300 is arranged on both sides of the walking frame body 100; the walking frame body 100 includes a number of supporting frames 110, a tail support 120 and a number of idlers, and each supporting frame 110 can be Disassemble the connection, the tail support 120 is arranged at the end of the support frame 110, the idler 130 is installed on the support frame 110, and is detachably connected with the support frame 110; during work, due to The idler member 130 continues to rotate d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com