A reactor for enhancing the stability of granular sludge

A sludge stabilization and particle enhancement technology, which is applied in the field of water pollution control, can solve problems such as uneven screen water distribution, achieve uniform water distribution without dead zones, and solve the phenomenon of granular sludge instability and hydraulic shear speed. Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

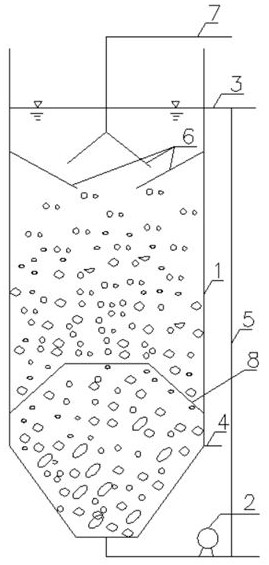

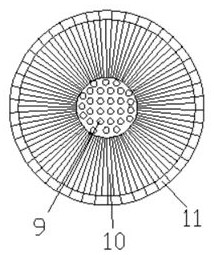

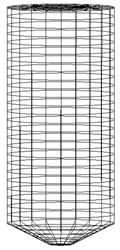

[0024] Using the fluid dynamics (CFD) software Fluent to simulate the flow field distribution in the UASB reactor without the above-mentioned uneven screen member and the UASB reactor of the present invention, establish a three-dimensional solid model with Solidwork, and divide and process the reactor grid with ICEM , the UASB reactor geometric grid and the UASB reactor geometric grid of the present invention that do not contain the above-mentioned uneven screen members are respectively as follows image 3 with Figure 4 shown. The water inlet is a flow rate inlet, the water inlet flow rate is 2m / h, and the outlet is a pressure outlet. The flow field distribution in the UASB reactor without the above-mentioned uneven screen member and the UASB reactor of the present invention is respectively as follows Figure 5 with Image 6 As shown, the distribution of the flow field in the reactor of the present invention is more uniform, there is basically no dead zone, and the hydrauli...

Embodiment 2

[0026] Adopt common UASB reactor and UASB reactor of the present invention to treat nitrate waste water, add flocculent sludge in reactor before water inflow, make sludge concentration reach 8g / L; Next, pump in reactor Into the nitrate wastewater, with methanol as the carbon source, the volume load of nitrate nitrogen is 1Kg / (m 3 •d), the reactor is continuously fed with water.

[0027] After 23 days of operation, no granular sludge was formed in the ordinary UASB reactor, and the sludge concentration increased to 14.4g / L; the flocculent sludge in the reactor of the present invention was converted into granular sludge, and the sludge concentration increased to 22.3g / L.

[0028] When continuing to operate for 42 days, granular sludge is formed in the ordinary UASB reactor, and the sludge concentration rises to 21.5g / L; the granular sludge concentration in the reactor of the present invention remains at 24g / L.

[0029] On the 43rd-46th day, gradually increase the nitrate nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com