Axial flow fan blade structure, axial flow fan and preparation method of axial flow fan

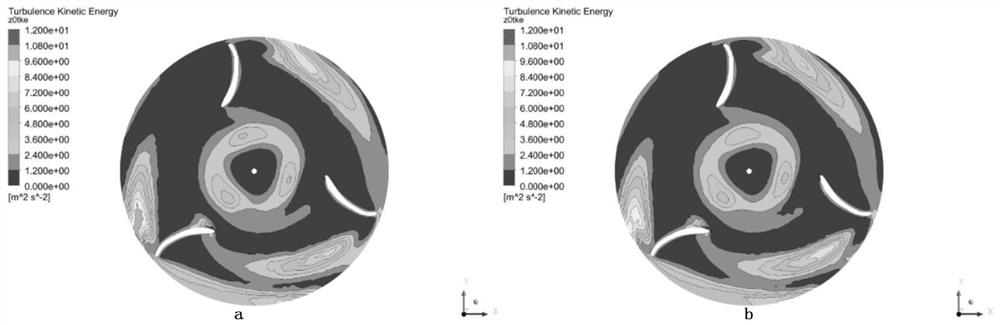

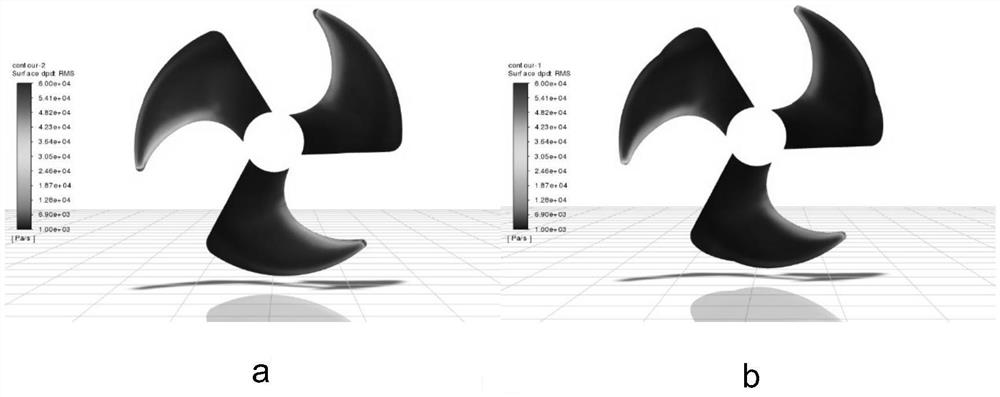

A technology of axial flow blades and axial flow fans, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of axial flow fan noise impact, product cost increase, high processing accuracy requirements, etc., to reduce turbulence Kinetic energy intensity, improvement of flow state, improvement of internal flow field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

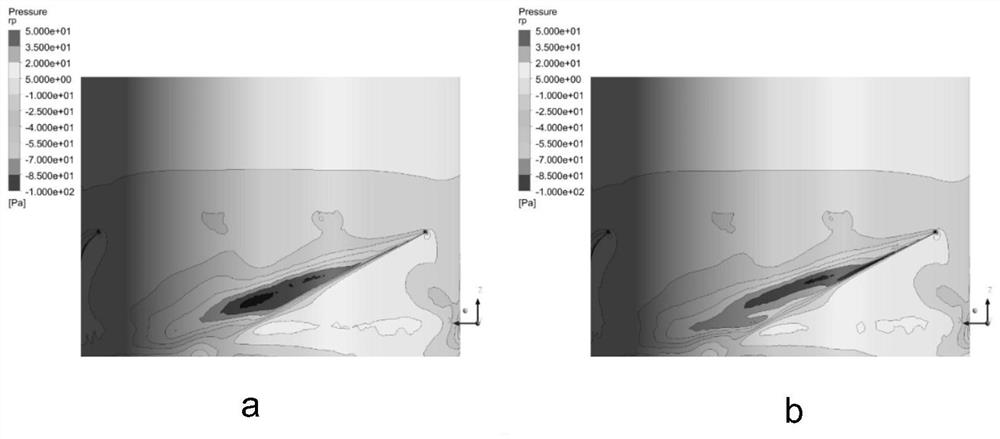

[0058] Such as Figure 2 to Figure 7 As shown, the structure of the axial flow blade includes the blade hub 1100, the axial flow blade 1200 and the blade shaft hole 1300, and the centerlines of the blade hub and the blade shaft hole coincide with the rotation axis of the axial flow blade. The axial-flow blades are evenly connected in the circumferential direction of the hub, and the three edges of the axial-flow blades are the leading edge 1210 of the blade, the trailing edge 1220 of the blade, and the outer edge 1230 of the blade. The presence of concave features on the outer edge of the blade divides the outer edge into front 1231 and rear 1232 convex features.

[0059] Such as Figure 7 As shown, an axial flow fan includes a blade hub 1100 , axial flow blades 1200 , and a wind guide ring 1400 . The wind guide ring includes an arc segment 1410 , a vertical segment 1420 and an outlet segment 1430 . The arc segment 1410 extends inwards along the arc line with a reduced radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com