Method for reducing emission of SO2 in sintering and distributing process based on ammonia additive

An additive and SO2 technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of reducing urea usage, poor removal effect, large urea usage, etc., to achieve reduced usage and uniform distribution , Guarantee the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

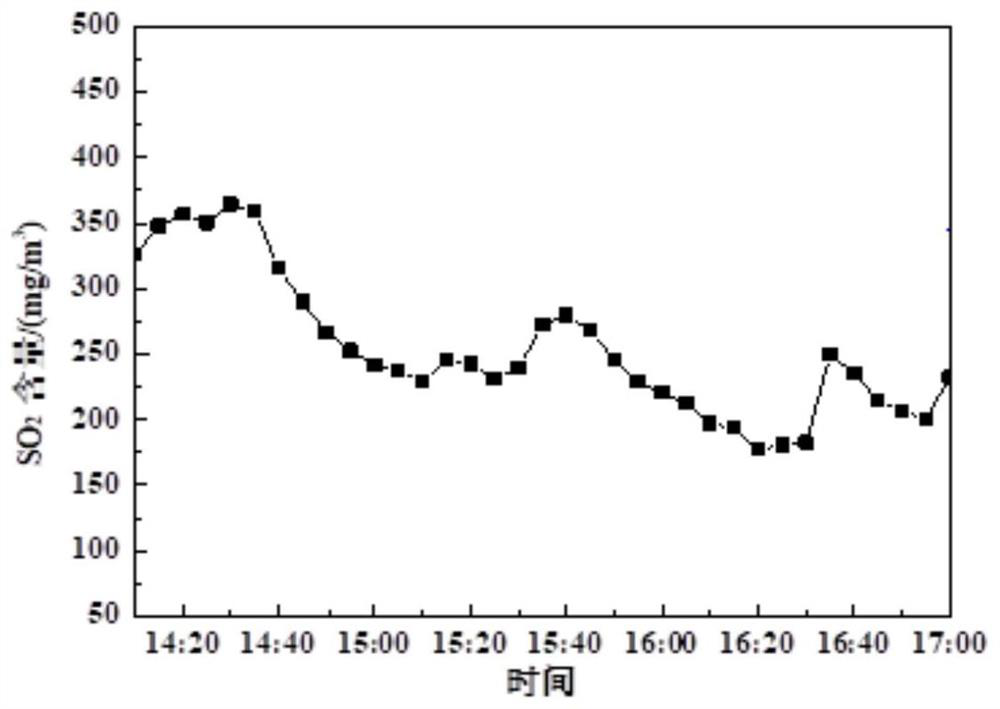

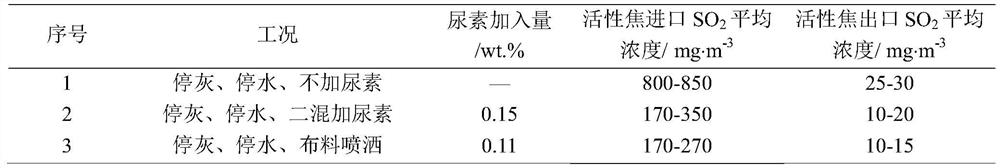

[0024] SO emission reduction in the process of sintering cloth based on ammonia additives in this embodiment 2 method, the process is:

[0025] (1) Preparation of urea solution: check the electric stirring device, steam facilities, infusion pump and various valves, add urea and water into the solution tank and mix thoroughly, and prepare a urea solution with a concentration of 40%.

[0026] (2) Spraying of urea solution: Taking the nine-roll fabric as an example, the feeding capacity of the sintering machine is 800t / h, and 18 nozzles are used to spray urea solution, and the 18 nozzles are divided into 6 groups, each with 3 nozzles Nozzle, the nozzle is perpendicular to the material surface, 200-300mm away from the material surface. The size of the main pipe in the solution pipeline is DN50, the size of the 6 branch pipes is DN25, the size of the 18 spray pipes is DN15, the model of the nozzle is 1 / 8HH-S316L-3.6WSQ, and the spray angle is 60°. And in the whole process, its ur...

Embodiment 2

[0031] SO emission reduction in the process of sintering cloth based on ammonia additives in this embodiment 2 The method is basically the same as embodiment 1, and its difference is that its process is:

[0032] (1) Preparation of urea solution: check the electric stirring device, steam facilities, infusion pump and various valves, add urea and water into the solution tank for thorough mixing, and prepare a urea solution with a concentration of 37.5%.

[0033] (2) Spraying of urea solution: Taking the nine-roll fabric as an example, the feeding capacity of the sintering machine is 800t / h, and 18 nozzles are used to spray urea solution, and the 18 nozzles are divided into 6 groups, each with 3 nozzles Nozzle, the nozzle is perpendicular to the material surface, 200-300mm away from the material surface. The size of the main pipe in the solution pipeline is DN50, the size of the 6 branch pipes is DN25, the size of the 18 spray pipes is DN15, the model of the nozzle is 1 / 8HH-S31...

Embodiment 3

[0038] SO emission reduction in the process of sintering cloth based on ammonia additives in this embodiment 2 The method is basically the same as embodiment 1, and its difference is that its process is:

[0039] (1) Preparation of urea solution: check the electric stirring device, steam facilities, infusion pump and various valves, add urea and water into the solution tank for thorough mixing, and prepare a urea solution with a concentration of 38%.

[0040](2) Spraying of urea solution: Taking the nine-roll fabric as an example, the feeding capacity of the sintering machine is 800t / h, and 18 nozzles are used to spray urea solution, and the 18 nozzles are divided into 6 groups, each with 3 nozzles Nozzle, the nozzle is perpendicular to the material surface, 200-300mm away from the material surface. The size of the main pipe in the solution pipeline is DN50, the size of the 6 branch pipes is DN25, the size of the 18 spray pipes is DN15, the model of the nozzle is 1 / 8HH-S316L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com