Mo-V synergistic easy-to-weld steel plate with tensile strength of 1,000 MPa and production method thereof

A technology of tensile strength and synergistic effect, applied in the field of welding steel, can solve the problems that joint performance cannot meet high tensile strength, heat input energy welding cannot be realized, and welding efficiency is low, so as to achieve excellent resistance to temper softening energy, Guarantee service safety performance and efficient welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

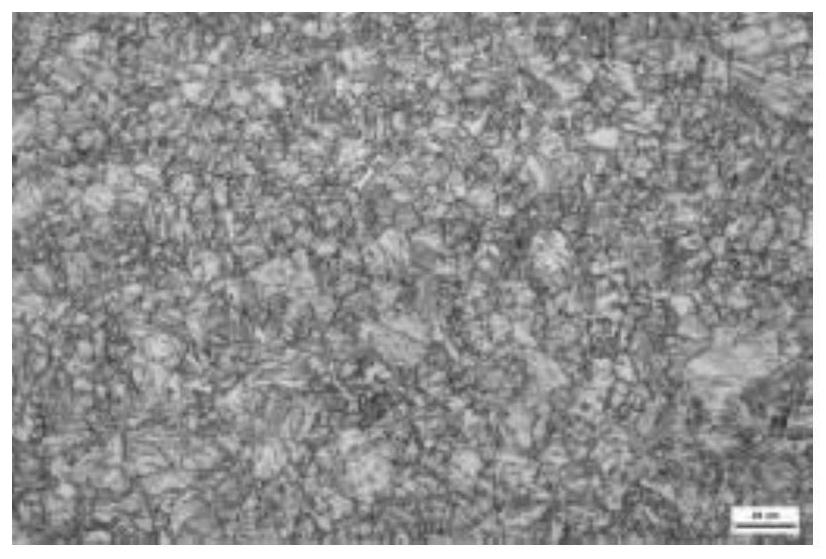

Image

Examples

Embodiment 1

[0055] This embodiment provides a Q890D easy-to-weld steel plate with a Mo-V synergistic tensile strength of 1000MPa, wherein the chemical composition mass percentage content of the steel is: C 0.09%, Si 0.22%, Mn 1.30%, Cr 0.35%, Mo0 .66%, V 0.065%, Ni 0.40%, Nb 0.35%, Ti 0.02%, P 0.008%, S 0.001%, B0.0009%, Al 0.015%, As 0.0035%, the rest is Fe and unavoidable inclusions thing. The thickness specification of the easy-to-weld steel plate is 16mm.

[0056] The production method of the above-mentioned Mo-V synergistic tensile strength 1000MPa easy-to-weld steel plate includes the following processes: smelting, casting, slab heating, rolling (including rough rolling and finish rolling), heat treatment (including quenching and tempering) and welding ,specifically,

[0057] Smelting includes: molten iron desulfurization, primary smelting, refining and vacuum degassing treatment; the molten iron containing various elements is desulfurized first, then sent to the converter for pri...

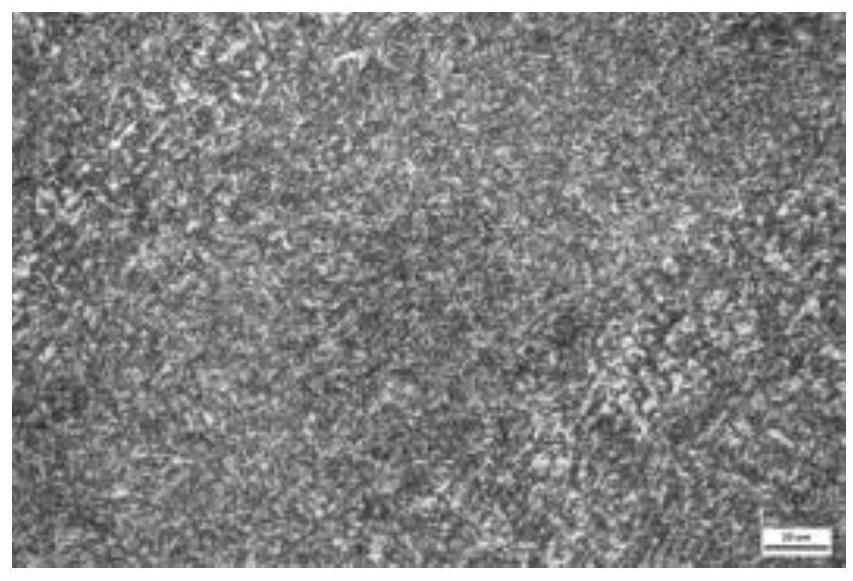

Embodiment 2

[0065] A Q890D easy-to-weld steel plate with a Mo-V synergistic tensile strength of 1000MPa, wherein the chemical composition of the steel is: C 0.10%, Si 0.25%, Mn 1.5%, Cr 0.40%, Mo 0.70%, V 0.059% , Ni0.35%, Nb 0.40%, Ti 0.020%, P 0.006%, S 0.002%, B 0.0012%, Al 0.025%, As0.004%, the balance is Fe and unavoidable inclusions. The thickness specification of the easy-to-weld steel plate is 30mm.

[0066] The production method of the above-mentioned Mo-V synergistic tensile strength 1000MPa easy-to-weld steel plate includes the following processes: smelting, casting, slab heating, rolling (including rough rolling and finish rolling), heat treatment (including quenching and tempering) and welding ,specifically,

[0067] Smelting includes: molten iron desulfurization, primary smelting, refining and vacuum degassing treatment; the molten iron containing various elements is desulfurized first, then sent to the converter for primary refining, and then sent to the LF refining furnac...

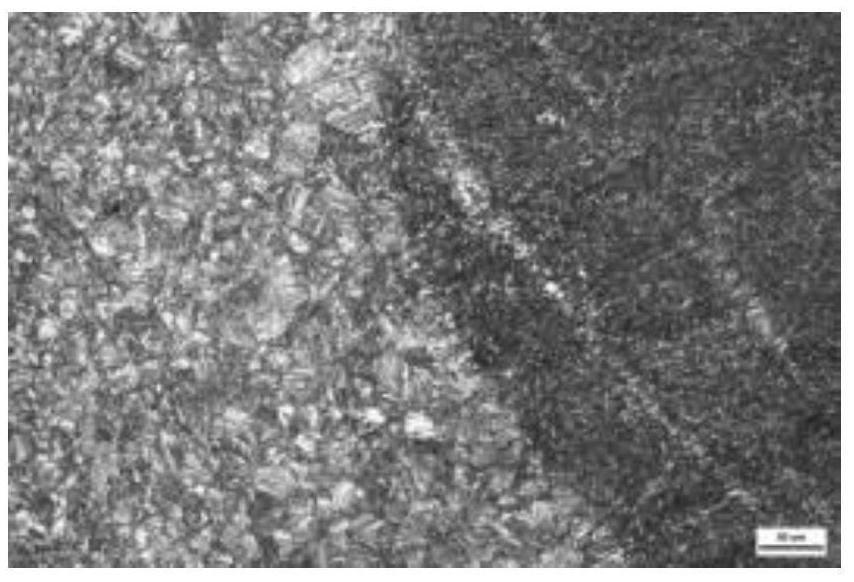

Embodiment 3

[0075] A Q890D easy-to-weld steel plate with a Mo-V synergistic tensile strength of 1000MPa, wherein the chemical composition of the steel is: C 0.11%, Si 0.21%, Mn 1.22%, Cr 0.41%, Mo 0.70%, V 0.068% , Ni0.45%, Nb 0.38%, Ti 0.018%, P 0.010%, S 0.003%, B 0.0009%, Al 0.030%, As0.0052%, the balance is Fe and unavoidable inclusions. The thickness specification of the easy-to-weld steel plate is 40mm.

[0076] The production method of the above-mentioned Mo-V synergistic tensile strength 1000MPa easy-to-weld steel plate includes the following processes: smelting, casting, slab heating, rolling (including rough rolling and finish rolling), heat treatment (including quenching and tempering) and welding ,specifically,

[0077] Smelting includes: molten iron desulfurization, primary smelting, refining and vacuum degassing treatment; the molten iron containing various elements is desulfurized first, then sent to the converter for primary refining, and then sent to the LF refining furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com