Sewage pipeline for municipal engineering

A sewage pipeline and engineering technology, which is applied in the sewer system, cleaning sewer, waterway system, etc., can solve the problems of easy cracks in the pipeline, unsmooth sewage transportation, and too simple structure, so as to achieve difficult condensation, improve stability, prevent crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

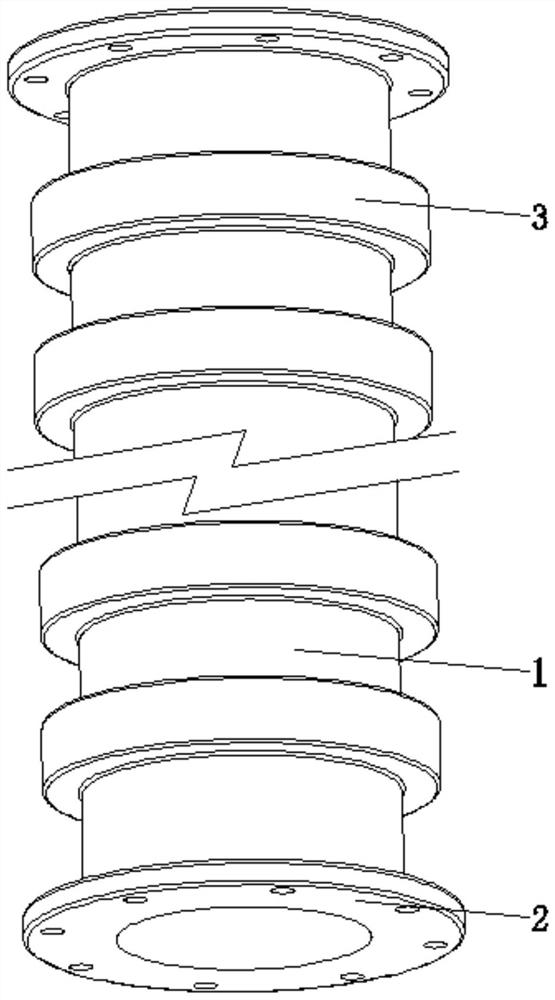

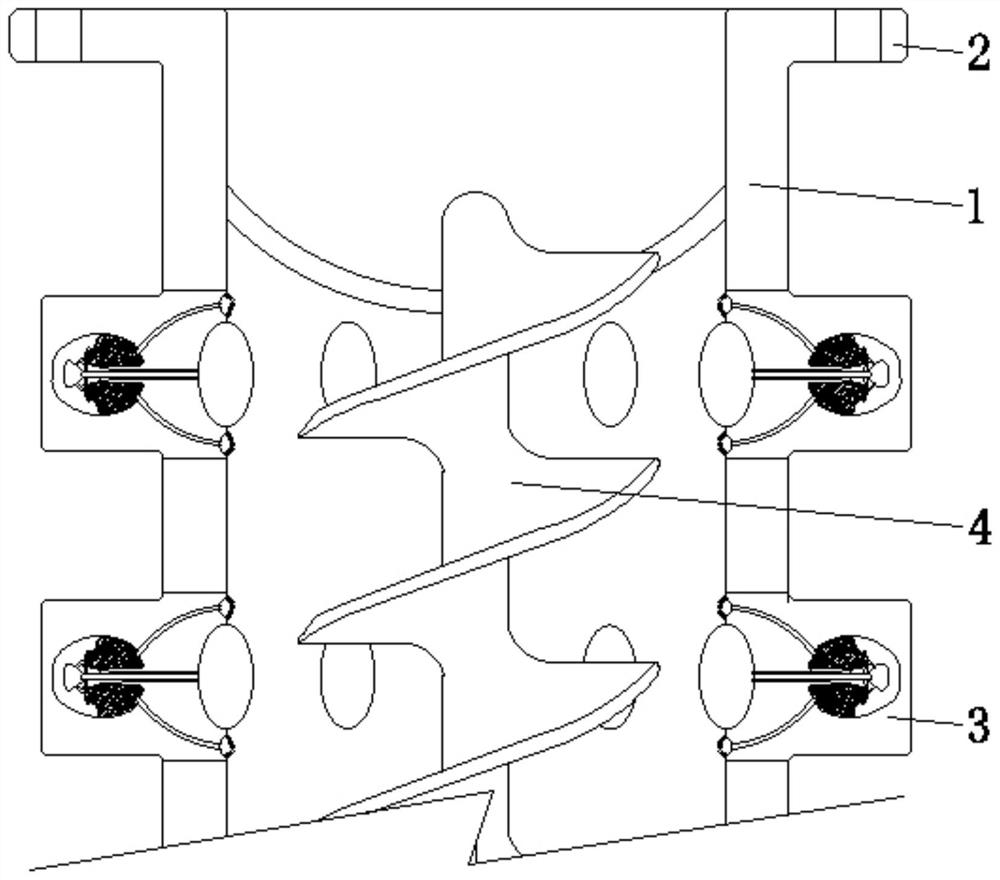

[0032] see Figure 1-7 , the present invention provides a technical solution: a sewage pipeline for municipal engineering, including a pipe body 1, a connecting flange 2, a treatment device 3, and a spiral blade 4, and is characterized in that: the connecting flange 2 is arranged at the end of the pipe body 1 part, the processing device 3 is fixed on the surface of the pipe body 1, and the spiral blade 4 is arranged at the inner center of the pipe body 1 and fixedly connected with the inner wall of the pipe body 1;

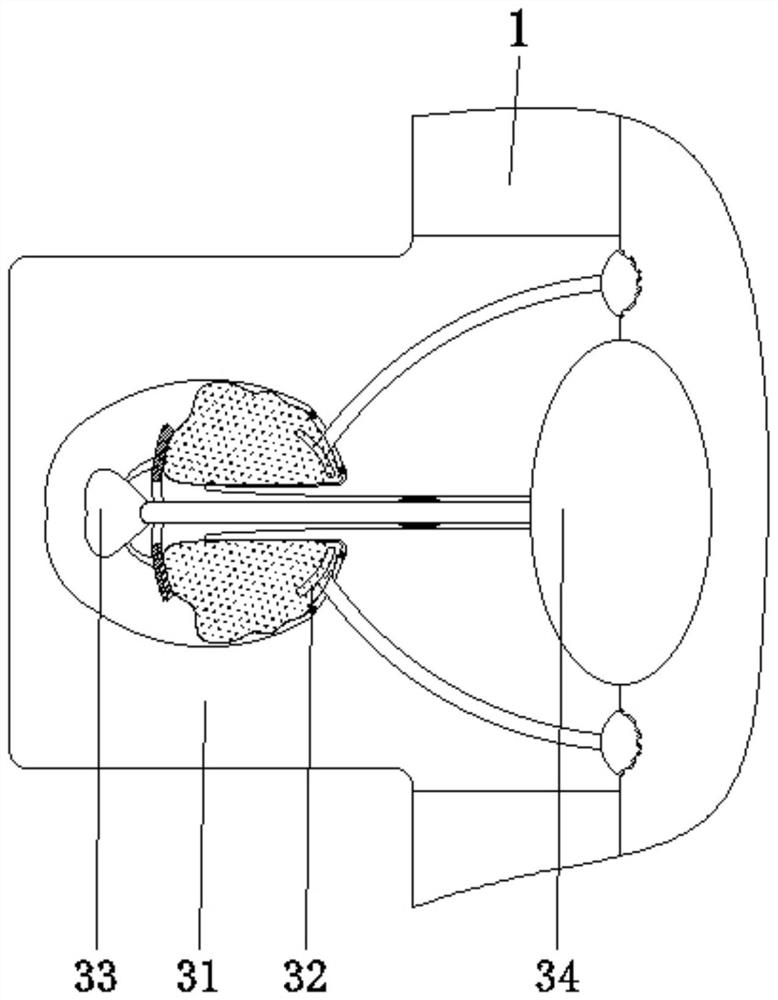

[0033] The processing device 3 is provided with a reference ring 31, a detection device 32, a heating block 33, and a crushing device 34. The surface of the reference ring 31 is fixedly connected to the surface of the pipe body 1, and the detection device 32 is arranged on both sides corresponding to the interior of the reference ring 31. The heating block 33 is arranged inside the reference ring 31 and fixed at one end of the detection device 32. The crushing dev...

Embodiment example 2

[0037] The crushing device 34 is provided with a fixed block 341, a push rod 342, a sealing ring 343, a cutting device 344, and an elastic reset member 345. One side of the surface of the fixed block 341 is fixedly connected with the inner wall of the reference ring 31, and the push rod 342 is slidably connected to the fixed block. 341, the sliding connection between the push rod 342 and the reference ring 31, the sealing ring 343 is sleeved on the surface of the push rod 342 and fixed on the surface of the fixed block 341, the cutting device 344 is arranged inside the fixed block 341 and is connected with The end of the push rod 342 is fixedly connected, and the two ends of the elastic reset member 345 are respectively arranged on the two sides corresponding to the surface of the cutting device 344 and the interior of the fixed block 341. When the temperature conducting device 321 detects low-temperature sewage, the bladder 322 The shrinkage makes the heating block 33 push the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com