Device and application as well as coal underground gasification leakproofness evaluation system and method

A stress-strain and experimental technology, applied in coal gasification, underground mining, earthwork drilling and mining, etc., can solve the lack of dynamic detection means for crack development, the inability to simulate the occurrence state of coal seams, and the inability to realize the development of water-conducting fissure zones in gasification areas. Communication on issues such as aquifer status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

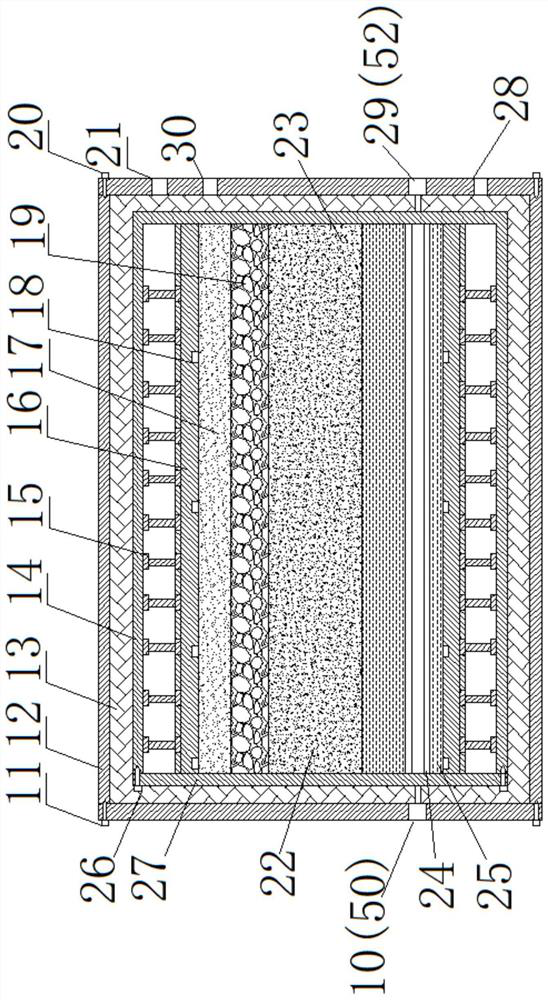

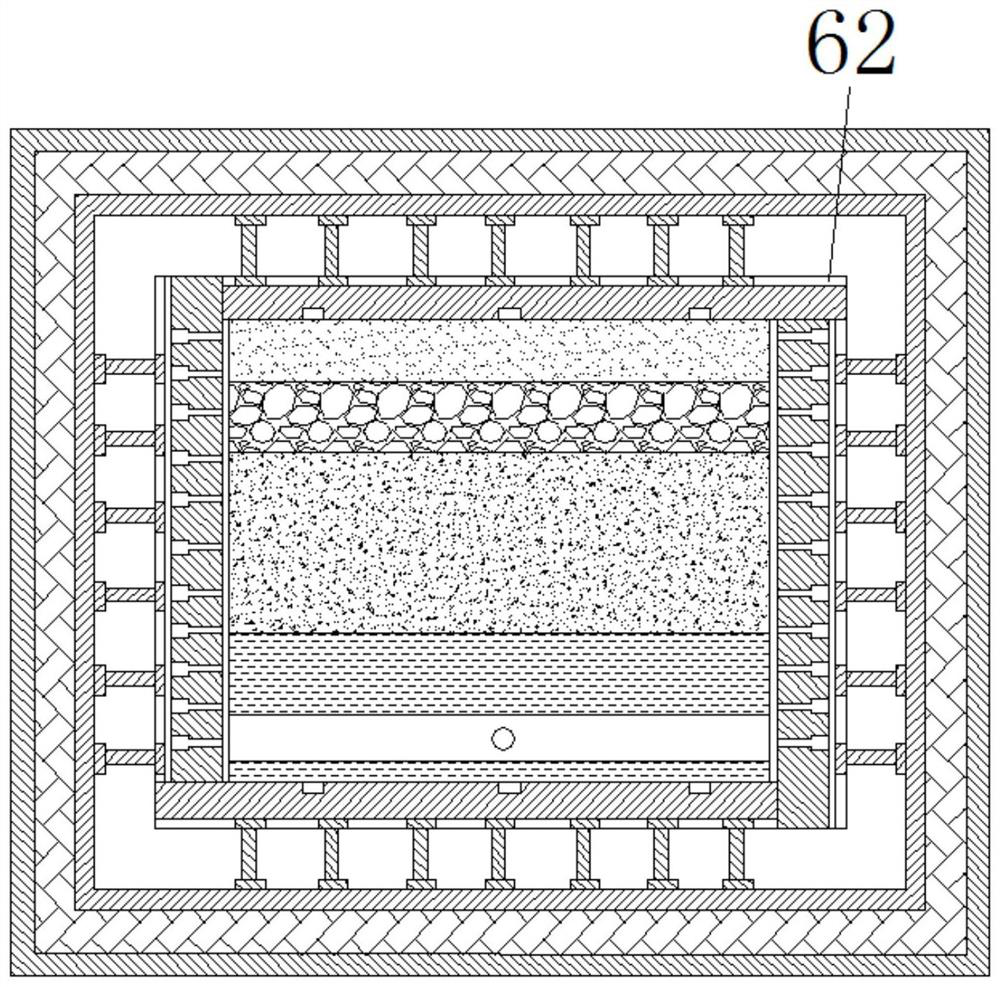

[0109] This embodiment provides a kind of airtight evaluation device applicable to the pollution evaluation of underground coal gasification. The structure of the airtight evaluation device is as follows: Figure 1-Figure 11 As shown, it specifically includes the airtightness evaluation device body (i.e. the experimental cabin),

[0110] The airtightness evaluation device body is provided with a gasification chamber 62 (i.e. an experimental chamber), an airtightness evaluation device shell (i.e. an experimental cabin shell) and refractory bricks 13; the airtightness evaluation device shell is located outside the gasification chamber 62, and the refractory bricks 13 is located in the cavity between the shell of the airtightness evaluation device and the gasification chamber 62; wherein,

[0111] The shell of the airtightness evaluation device is made of high-pressure resistant steel plate with a thickness of 1cm, which can withstand high pressure of 35MPa and high temperature o...

Embodiment 2

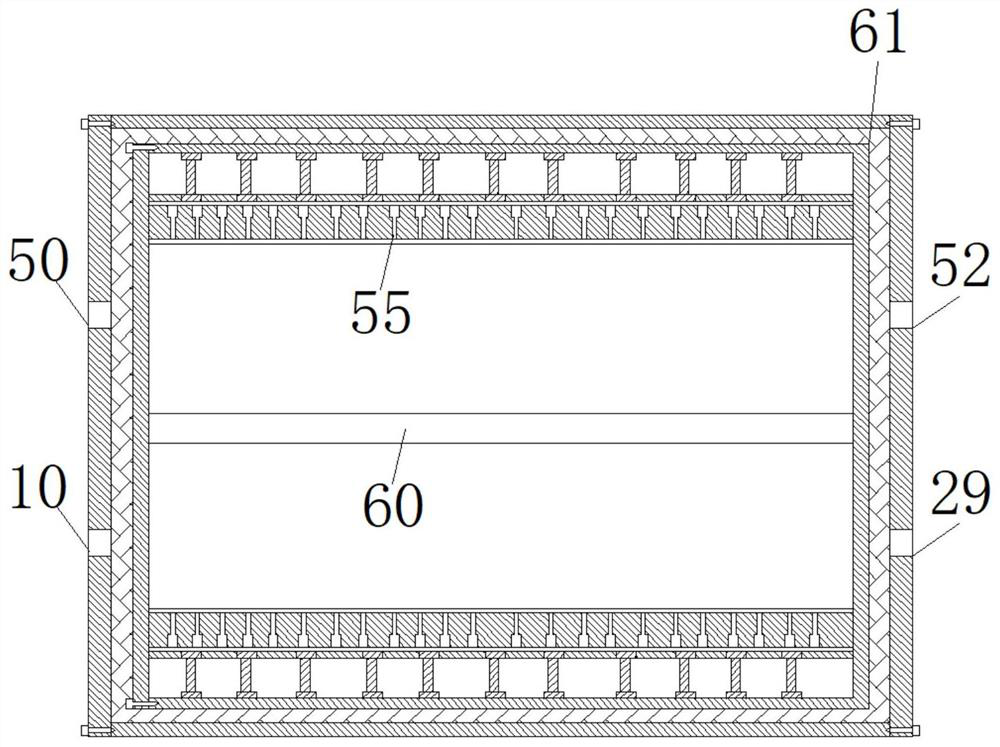

[0119] This embodiment provides an underground coal gasification pollution evaluation system applicable to underground coal gasification pollution evaluation. The underground coal gasification pollution evaluation system is as follows: Figure 12-Figure 15 As shown, it specifically includes the airtightness evaluation device provided in Example 1, gasification agent preparation unit, confining pressure, pore pressure loading unit, synthesis gas processing unit, data acquisition unit and ignition unit; gasification agent preparation unit and airtightness evaluation The gasification agent injection channel 10 of the device is connected to inject the gasification agent into the airtightness evaluation device; The confining pressure injection pipeline is connected with the pore pressure injection pipeline to apply confining pressure and pore pressure to the airtightness evaluation device; the synthesis gas processing unit is connected with the first syngas output channel 29 of the ...

Embodiment 3

[0128] This embodiment provides a method for evaluating airtightness of underground coal gasification, which uses the pollution evaluation system for underground coal gasification provided in Example 2 to carry out the process as follows Figure 16 As shown, the method includes:

[0129] 1) Prepare the roof, floor 25 and coal seam 24 for the gasification test: Carry out rock mechanics tests according to the core data of the roof and floor of the coal seam in the area to be simulated, and measure the mechanical properties (elastic modulus, Poisson's ratio, tensile strength, compressive strength), combined with the principle of material similarity to prepare the top plate and bottom plate 25 for gasification tightness evaluation; the roof includes the direct roof 23 of the coal seam and the indirect roof, and the indirect roof includes a tight water-resisting layer 22, an aquifer 19 and an upper formation 17 , the upper formation 17 is 0.25m thick, 2.2m long, and 1.5m wide, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com