Self-cleaning engine

An engine and self-cleaning technology, which is applied to machines/engines, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as troublesome cleaning of carbon deposits in the engine, and achieve the effect of improving the cleaning effect, timely cleaning, and increasing the cleaning area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

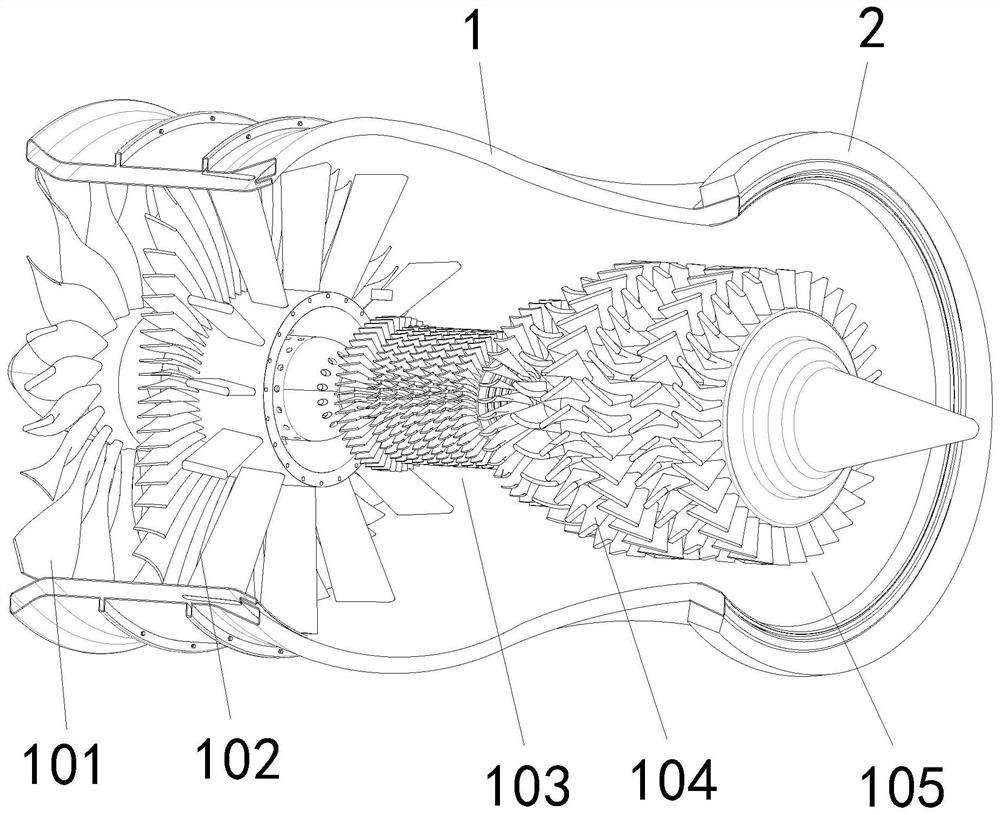

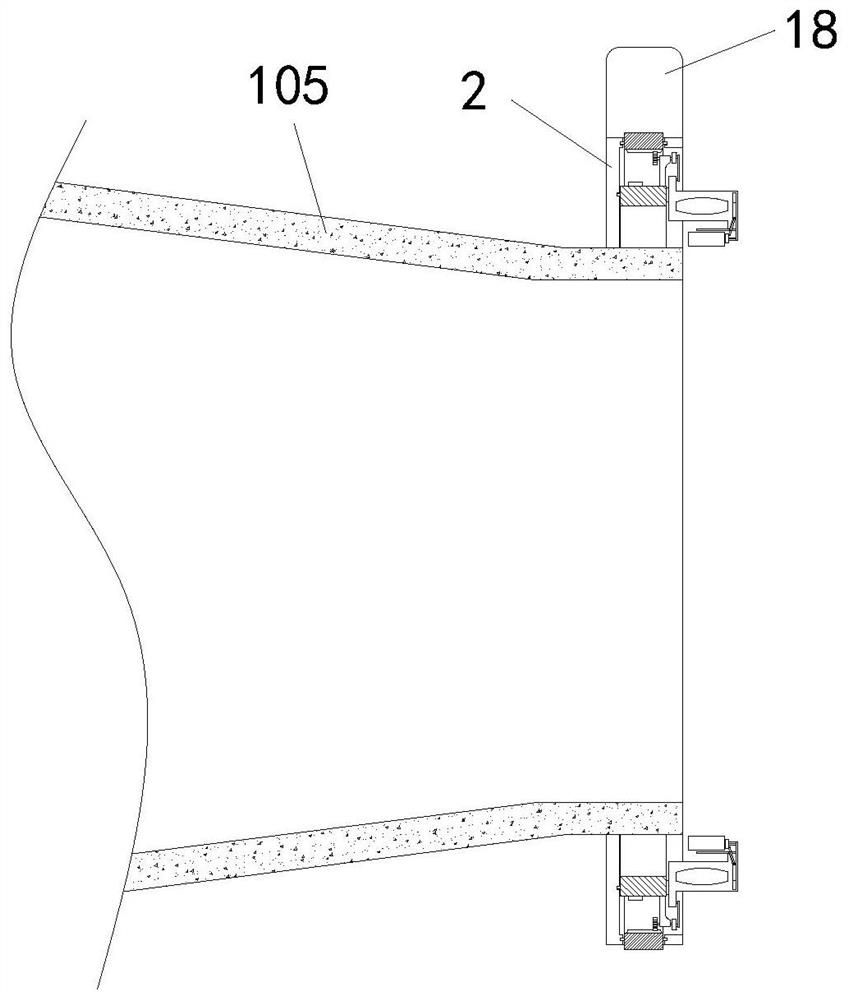

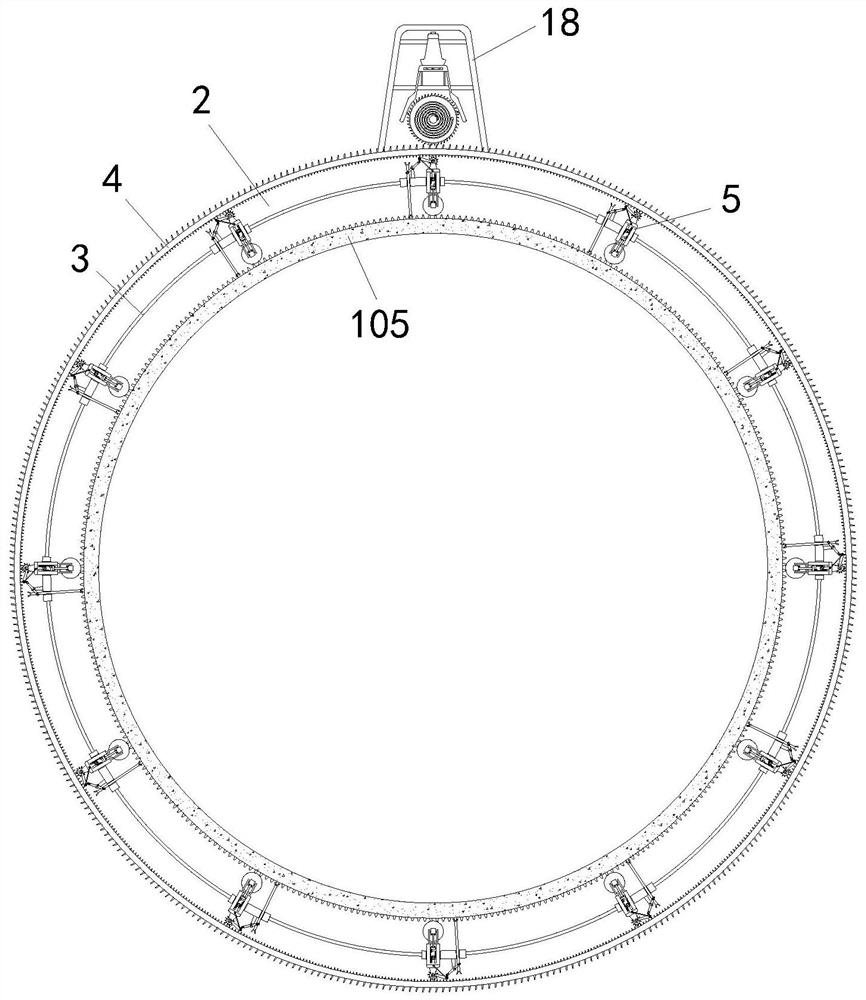

[0036] Such as Figure 1 to Figure 7 As shown, the self-cleaning engine of the present invention includes an engine main body 1 and a tail nozzle 105, a support ring 2 is fixedly installed on the outside of the tail nozzle 105, and a slidable movable seat 5 is installed inside the support ring 2, The bottom end of the movable seat 5 is provided with a cleaning brush 6. During work, under the initial state, the cleaning brush 6 is positioned at the outside of the tail nozzle 105, which will not affect the jet work of the tail nozzle 105. When cleaning, move the movable seat 5. Make the cleaning brush 6 move to contact with the inner wall of the tail nozzle 105, and then drive the cleaning brush 6 to roll along the inner wall of the tail nozzle 105, so as to remove the carbon deposit on the inner wall of the tail nozzle 105.

[0037] Described engine main body 1 comprises intake passage 101, compressor 102, combustion chamber 103, turbine mechanism 104, tail pipe 105 and accesso...

Embodiment 2

[0046] Such as Figure 8 to Figure 9 As shown in Comparative Example 1, another embodiment of the present invention is: a switch seat 24 is fixedly installed inside the main seat 18, a pressure ball 25 is placed inside the switch seat 24, and the inside of the switch seat 24 is located A baffle is arranged below the pressure ball 25, and a through hole corresponding to the pressure ball 25 is provided in the inside of the baffle, and the diameter of the through hole is smaller than the diameter of the pressure ball 25. 25 corresponds to the arm bar 26, the end portion 26 of the arm bar is inserted below the pressure ball 25, and the end portion 26 of the arm bar is located above the baffle plate, and the bottom end of the switch base 24 is provided with a switch for controlling the spring assembly 20 Key 27, switch key 27 is positioned at the below of touch pressure ball 25, and during work, switch key 27 is used for controlling the locking and activity of clockwork assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com