Final-stage passivation method for liquid oxygen kerosene of carrier rocket

A carrier rocket and liquid oxygen kerosene technology, which is applied to rocket engine devices, aerospace vehicle propulsion system devices, machines/engines, etc., can solve the problems of few researches on the last-stage passivation scheme, and achieve simplified rocket design and improved The effect of economy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings.

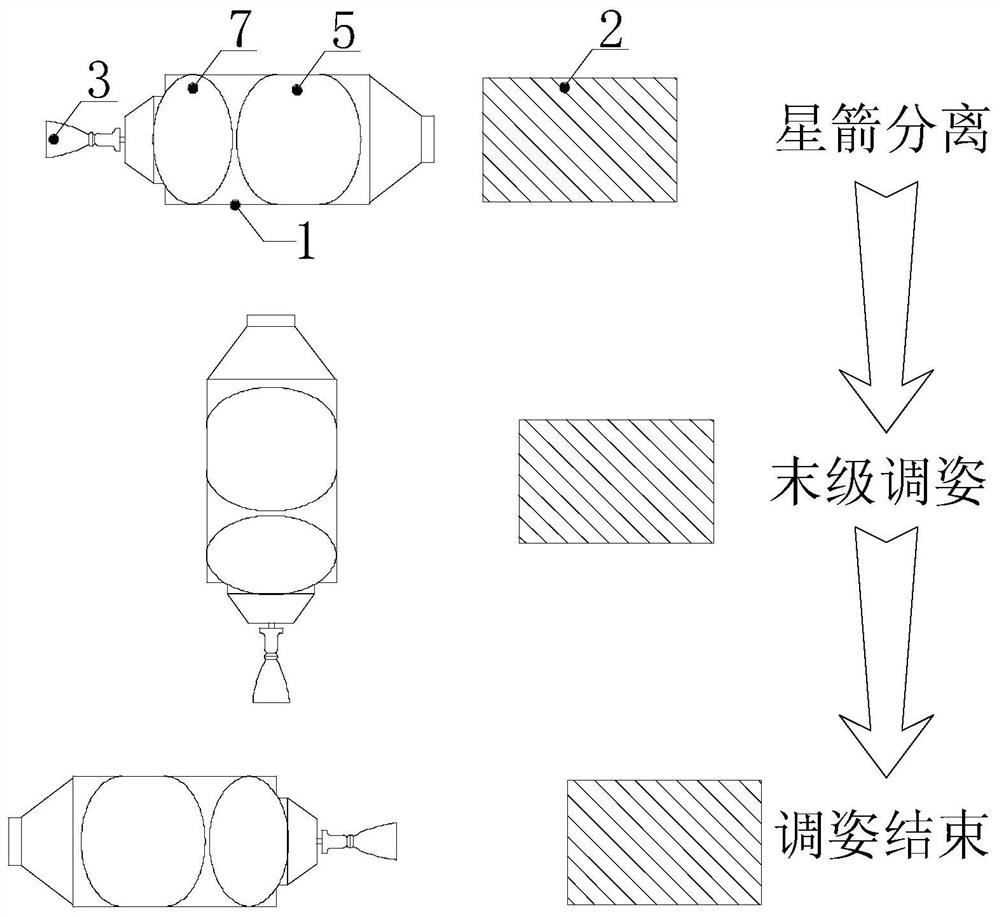

[0027] figure 1 It is a schematic diagram of the attitude adjustment of the final stage of the present invention. After the launch vehicle 1 is separated from the satellite 2, the attitude of the rocket body is adjusted, so that the thrust of the main engine 3 is basically in the opposite direction of the flight speed.

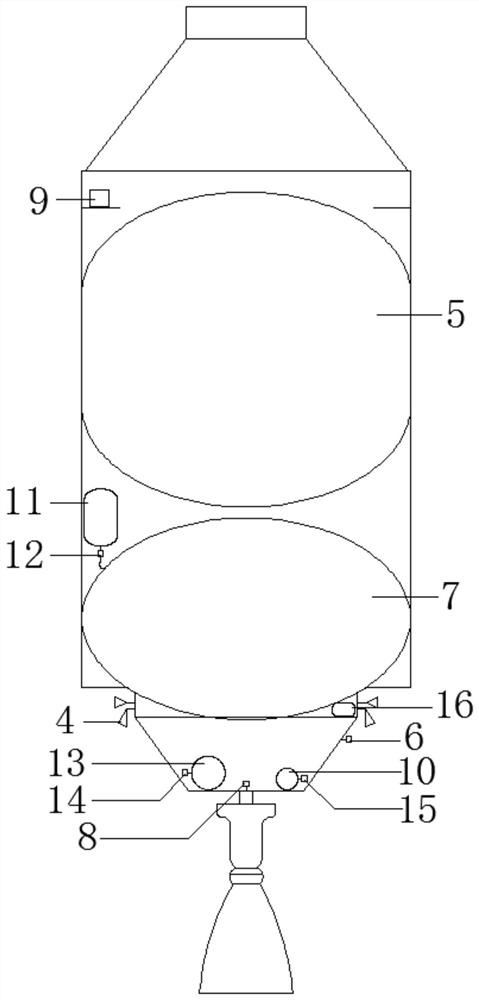

[0028] figure 2 It is the layout diagram of the passivation objects on the final arrow of the present invention, and the objects that need to be passivated include the liquid oxygen in the liquid oxygen storage tank 5, the kerosene in the kerosene storage tank 7, the pressurized gas cylinder 11 of the storage tank, the main engine blower Degassing cylinder 13, main engine control gas cylinder 10, auxiliary power system 16 and battery 9, wherein the liquid oxygen in the liquid oxygen storage tank 5, the kerosene in the kerosene storage tank 7, the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com