Dry-type transformer with high-temperature protection function

A dry-type transformer and protection function technology, applied in the direction of transformer/inductor housing, transformer/inductor cooling, transformer/inductor components, etc. Dry-type transformer damage and other problems, to achieve the effect of improving service life, reducing the risk of bursting, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

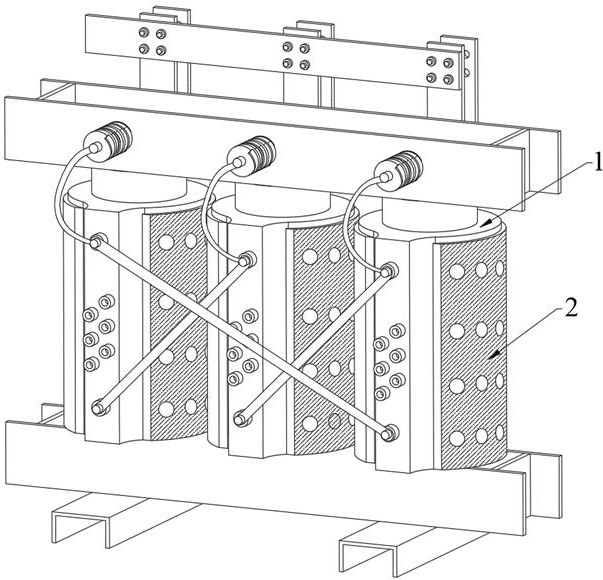

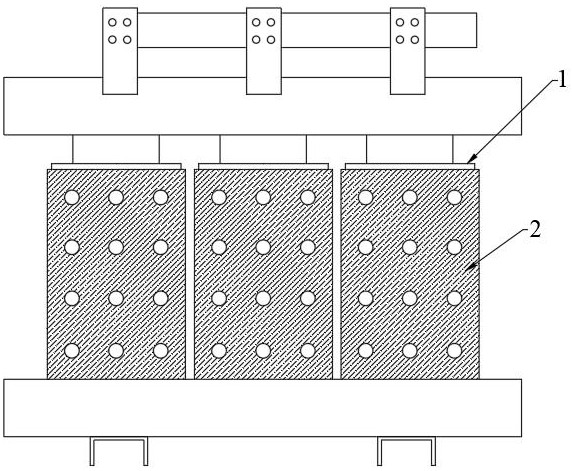

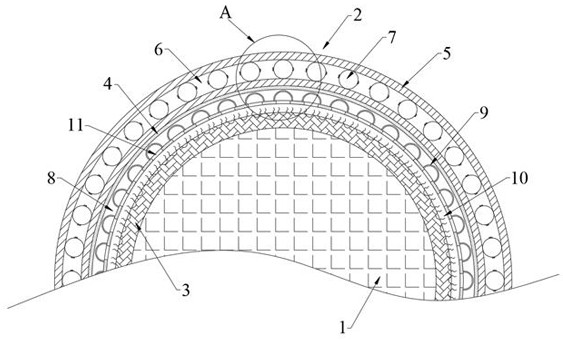

[0043] see Figure 1-4 and Image 6 , a dry-type transformer with high temperature protection function, including a transformer body 1, the outer wall of the transformer body 1 is provided with a protective cover 2, the protective cover 2 includes a heat conducting layer 3, a trigger layer 4 and an outer sheath 5, and the heat conducting layer 3 One end of the transformer body is attached to the outer wall of the transformer body 1. The trigger layer 4 is located between the heat conducting layer 3 and the outer sheath 5. There are several first cavities 6 inside the outer sheath 5. Several first cavities 6 are fixedly connected inside the first cavity 6. Protective deformation ball 7, several second cavities 8 are provided inside the trigger layer 4, several elastic membranes 9 are fixedly connected inside the second cavity 8, and several cooling chambers are provided on the side of the trigger layer 4 close to the heat conduction layer 3. Groove 10, the cooling groove 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com