Integrated slide wire alternating current ice melting controller

A controller and trolley wire technology, which is applied in the direction of converting AC power input to AC power output, AC power input converting to DC power output, cable installation, etc. problem, to achieve the effect of volume reduction, cost reduction, and quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

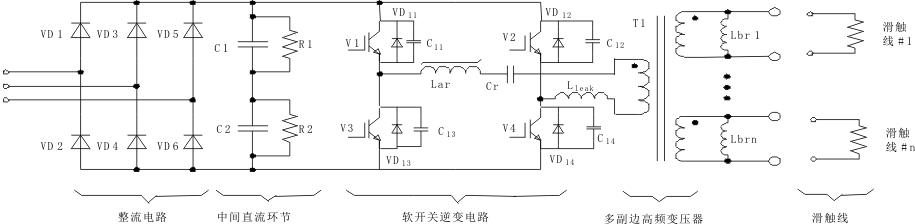

[0017] according to figure 1 As shown, this embodiment provides an integrated trolley line AC ice-melting controller, including a controller main circuit, the controller main circuit is composed of a controller module, and the controller module includes a module main circuit, The main circuit of the module includes a rectifier circuit, an intermediate DC link circuit, an inverter circuit and a high-frequency transformer. The intermediate DC link circuit is composed of a capacitor and a resistor. The capacitor is used for energy storage and filtering of the intermediate DC link circuit, and the resistor The capacitor is voltage equalized, and the inverter circuit is composed of a one-way high-frequency inverter, and the one-way high-frequency inverter is composed of a power transistor, which converts the direct current of the intermediate direct current link circuit into a high-frequency single-phase alternating current , the high-frequency transformer is a multi-secondary stru...

Embodiment 2

[0026] according to figure 1 As shown, this embodiment provides an integrated trolley line AC ice-melting controller, including a controller main circuit, the controller main circuit is composed of a controller module, and the controller module includes a module main circuit, The main circuit of the module includes a rectifier circuit, an intermediate DC link circuit, an inverter circuit and a high-frequency transformer. The intermediate DC link circuit is composed of a capacitor and a resistor. The capacitor is used for energy storage and filtering of the intermediate DC link circuit, and the resistor The capacitor is voltage equalized, and the inverter circuit is composed of a one-way high-frequency inverter, and the one-way high-frequency inverter is composed of a power transistor, which converts the direct current of the intermediate direct current link circuit into a high-frequency single-phase alternating current , the high-frequency transformer is a multi-secondary stru...

Embodiment 3

[0035]according to figure 1 As shown, this embodiment provides an integrated trolley line AC ice-melting controller, including a controller main circuit, the controller main circuit is composed of a controller module, and the controller module includes a module main circuit, The main circuit of the module includes a rectifier circuit, an intermediate DC link circuit, an inverter circuit and a high-frequency transformer. The intermediate DC link circuit is composed of a capacitor and a resistor. The capacitor is used for energy storage and filtering of the intermediate DC link circuit, and the resistor The capacitor is voltage equalized, and the inverter circuit is composed of a one-way high-frequency inverter, and the one-way high-frequency inverter is composed of a power transistor, which converts the direct current of the intermediate direct current link circuit into a high-frequency single-phase alternating current , the high-frequency transformer is a multi-secondary struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com