A sintered NdFeB magnet automatic pulverizing device and automatic pulverizing method

A pulverizing device, NdFeB technology, applied in grain processing and other directions to achieve the effect of improving the pulverizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment discloses a method for producing a sintered NdFeB magnet, which specifically includes the steps:

[0057] Prepare a variety of raw materials, design their components, and calculate and weigh the ingredients according to the designed proportions to obtain a preliminary mixture.

[0058] The preliminary mixed material is smelted, followed by ingot / casting, crushing treatment, and multifunctional additives are added to obtain mixed powder.

[0059] The particle size distribution of the mixed powder was analyzed, and then the magnetic field orientation and pressing treatment, sintering treatment, and tempering treatment were sequentially performed to obtain a black body blank.

[0060] The black body blank is mechanically processed to obtain a white body blank, the white body blank is subjected to surface coating treatment and then cut, and a sintered NdFeB magnet is obtained after magnetization by sintering.

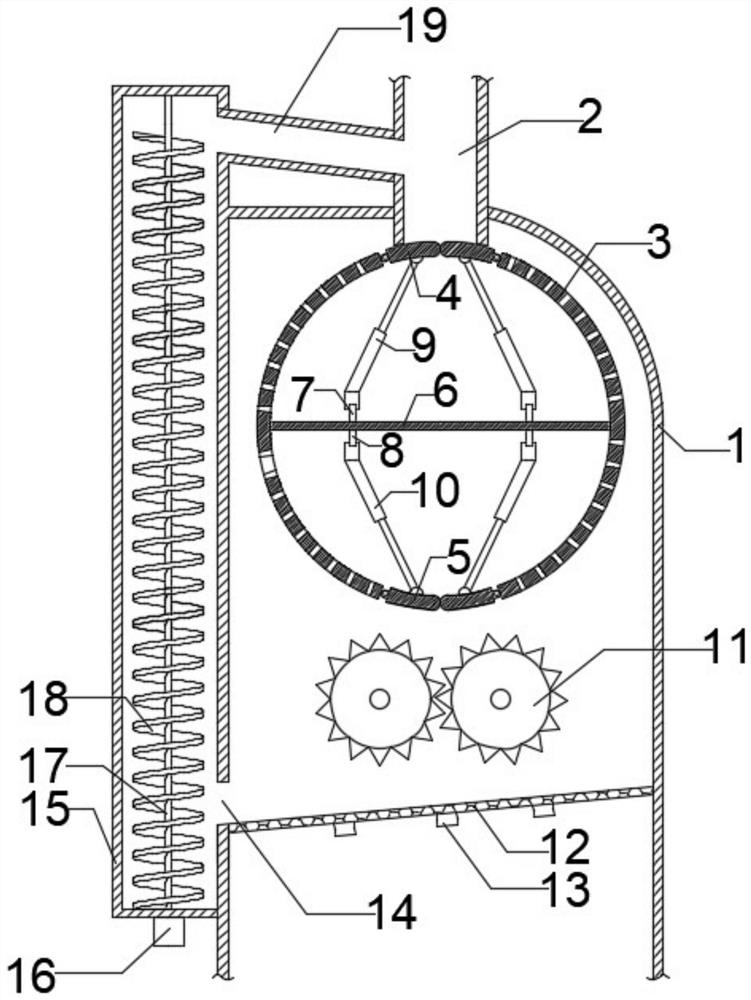

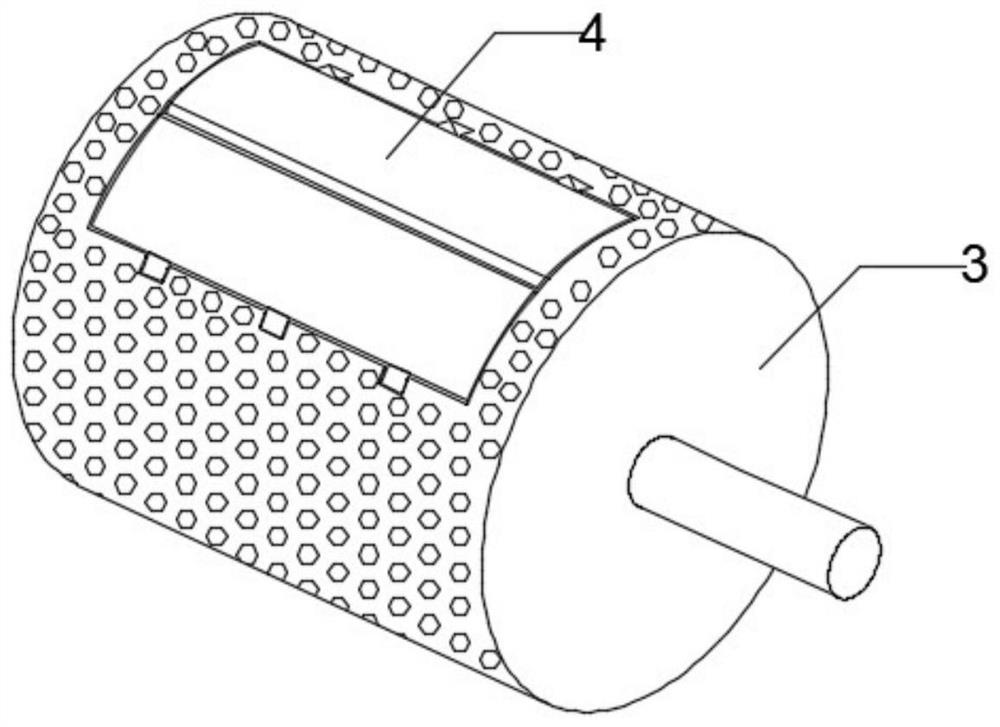

[0061] see figure 1 The present embodi...

Embodiment 2

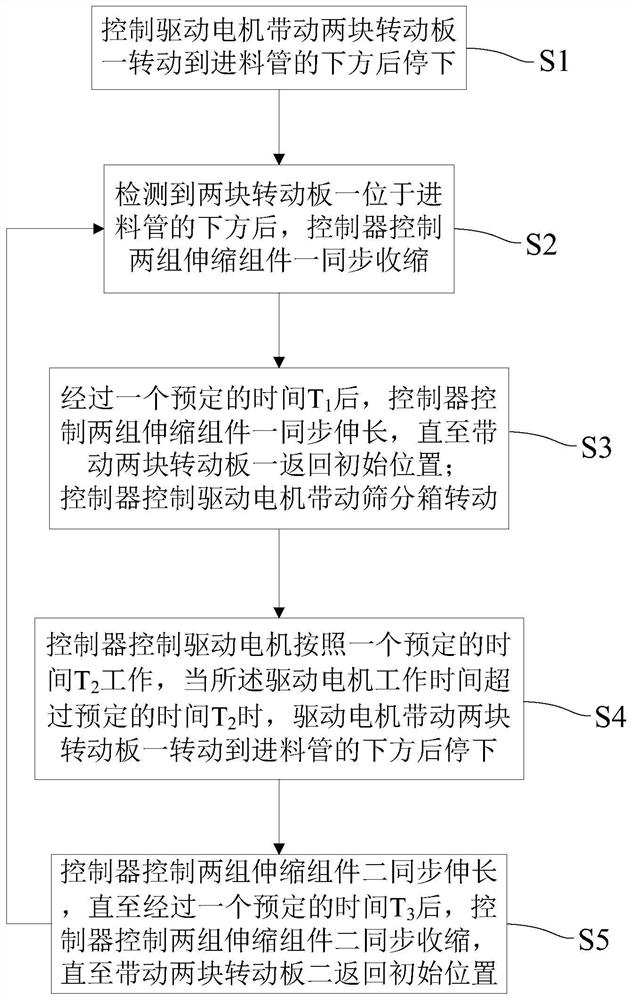

[0088] see Figure 4 , This embodiment introduces an automatic pulverizing method for sintered NdFeB magnets. The automatic pulverizing method is applied to the automatic pulverizing device for sintered NdFeB magnets in Example 1, which pulverizes the NdFeB magnets. The automatic crushing method includes the steps:

[0089] The NdFeB magnetic clusters are separated from the NdFeB magnetic powder by the sieving box 3 .

[0090] The separated NdFeB magnetic clusters are pulverized by the roller set 11 to obtain NdFeB magnetic powder and incompletely pulverized NdFeB magnetic clusters.

[0091] The NdFeB magnetic powder is separated from the incompletely crushed NdFeB magnetic clusters through the screen 12 , and the incompletely crushed NdFeB magnetic clusters are transported into the circulation bin 15 .

[0092] The incompletely pulverized NdFeB magnetic mass is transferred into the screening box 3 through the circulating component to realize circulating pulverization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com