Plate uncoiling and shearing die

A mold and sheet technology, applied in the field of shearing mold tooling, can solve the problems of increasing mold maintenance costs, easy deformation of feeding rollers, and cutting damage of non-metallic rollers, so as to reduce mold maintenance costs and avoid scratches. The effect of damage and avoidance of crushing and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

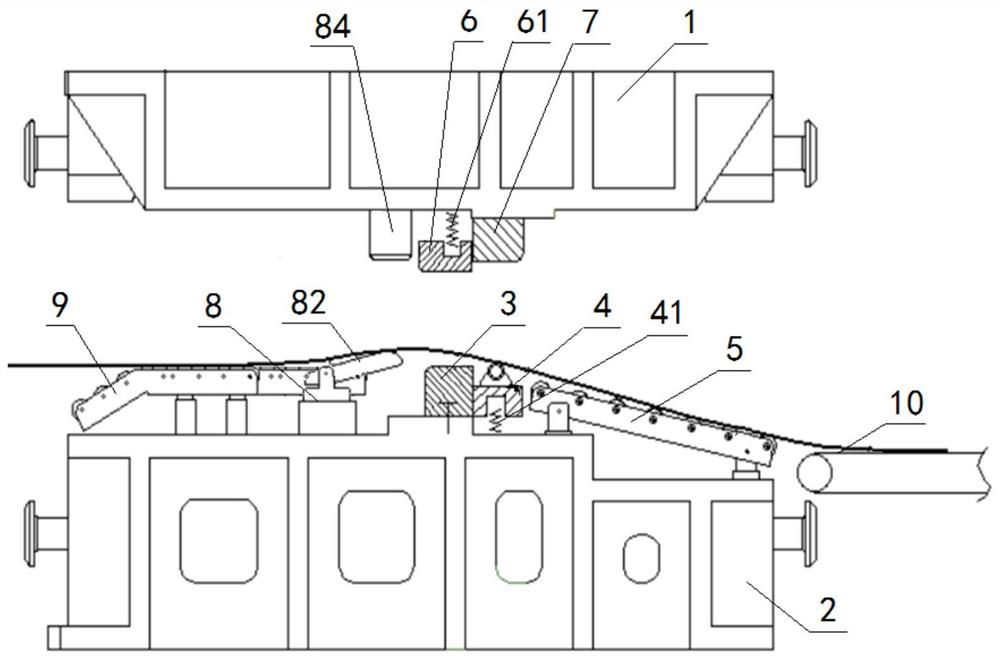

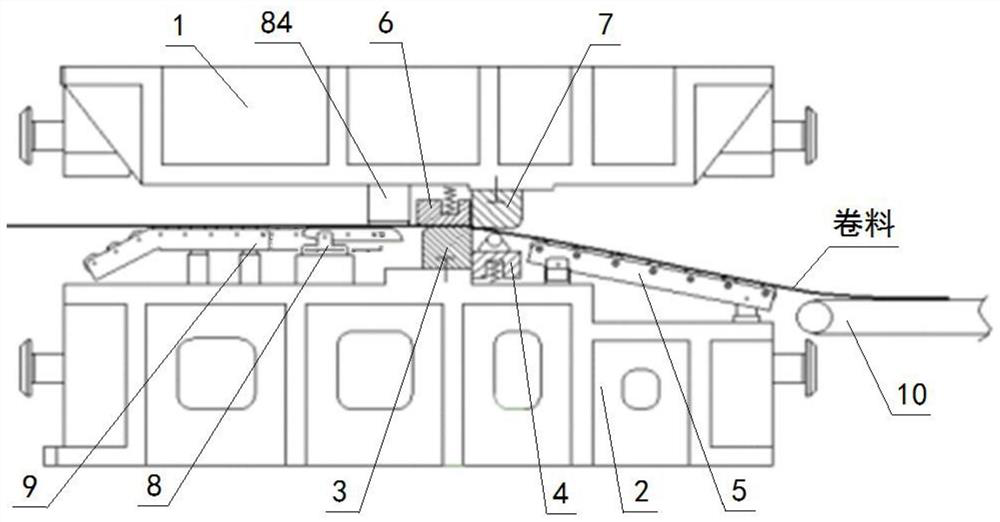

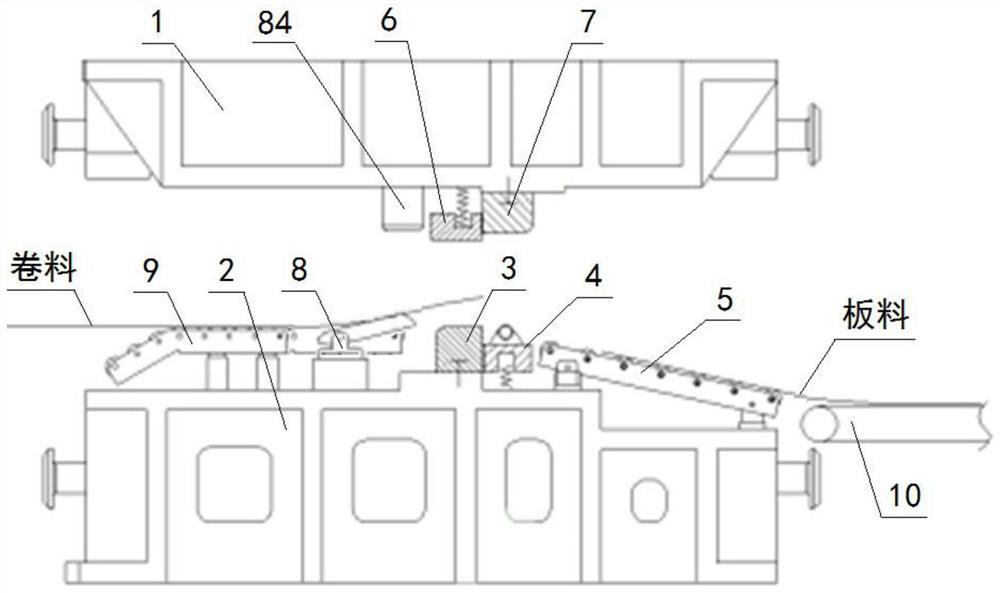

[0078] A sheet material uncoiling and shearing die, the sheet material uncoiling and shearing die comprises: an upper die base 1 and a lower die base 2, the upper die base 1 is located above the lower die base 2, the upper die base 1 and the lower die base The base 2 is matched; the top of the lower mold base 2 is sequentially provided with a lower mold knife block 3, an elastic support frame 4 and a discharge roller bar group 5 from the feed side to the discharge side; the lower mold knife block 3 It is fixedly arranged on the lower die base 2, and an elastic presser 6 is correspondingly arranged directly above the lower die block 3, and the top of the elastic presser 6 is connected to the bottom of the upper die base 1 through a presser spring 61 , the bottom of the elastic presser 6 is press fit with the top of the lower die block 3; the bottom of the elastic bracket 4 is connected with the top of the lower mold base 2 by the bracket spring 41, and the elastic bracket 4 Cor...

Embodiment 2

[0080] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0081]The elastic bracket 4 includes a roller seat 43 and a circular rolling body 42, and the rolling body 42 is arranged on the top of the roller seat 43; the bracket spring 41 includes a first bracket spring 411 and a first bracket spring 411. The second bracket spring 412, the bottom of the first bracket spring 411 is connected with the top of the lower mold base 2, and the top of the first bracket spring 411 is connected with one end of the roller seat 43, said The other end of the roller seat 43 is connected with the top of the second bracket spring 412, and the bottom of the second bracket spring 412 is connected with the top of the lower mold base 2; Each end is fixed with a spacer 44, and the spacer 44 is press fit with the corresponding boss 11 on the upper mold base 1; the roller seat 43 is provided with a guide screw 45, and the guide screw 45 The upper end of the guide screw 45 is ...

Embodiment 3

[0083] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0084] The rolling elements 42 are two cylindrical roller shafts 47, the two ends of each of the roller shafts 47 are respectively connected to the top of the roller seat 43 through a roller bracket 46, and the roller shafts 47 and the two ends of the roller shafts 47 are The roller support 46 is rotated and matched; the two ends of the top of the lower mold base 2 are respectively provided with two guide pillars 23, and the sides of the guide pillars 23 are provided with a storage limit column 24, and the storage limit column 24 is fixed on the lower On the die base 2; the two ends of the top of the lower die base 2 are each fixedly provided with a slide bar 21, and the slide bar 21 is positioned at the far side of the lower mold knife block 3 of the rotating supporting device 8, and the slide bar 21 The upper sleeve is provided with a limit block 22 , and the limit block 22 is slidingly match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com