An automatic equipment for realizing contact welding

A technology of automation equipment and contacts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of saving manual inspection procedures, saving adjustment materials, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

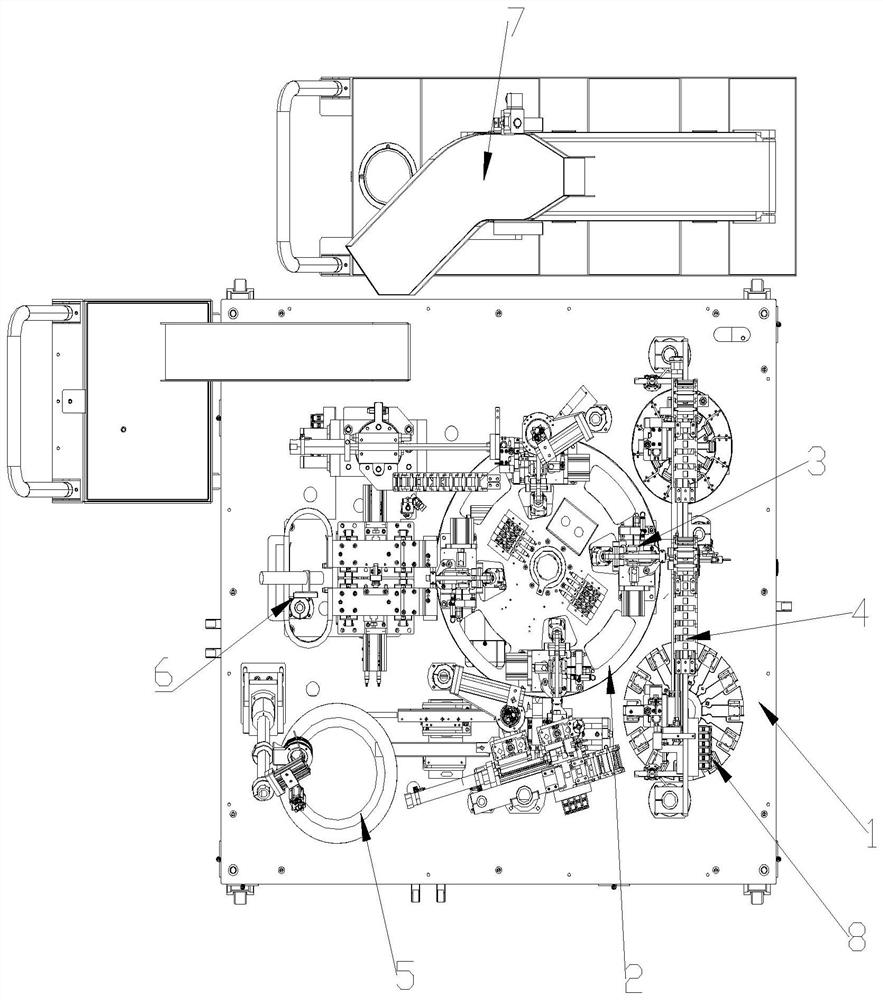

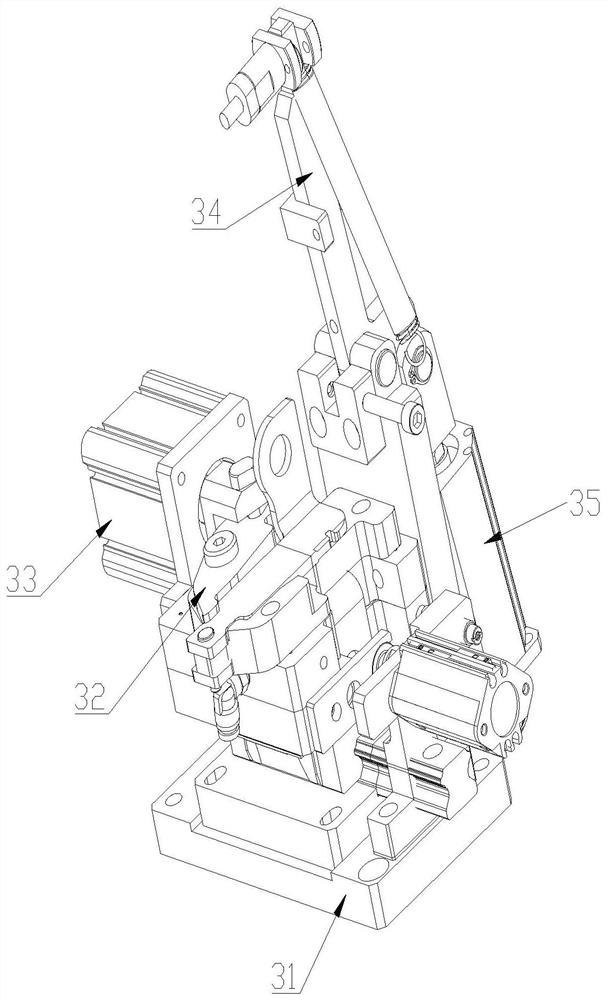

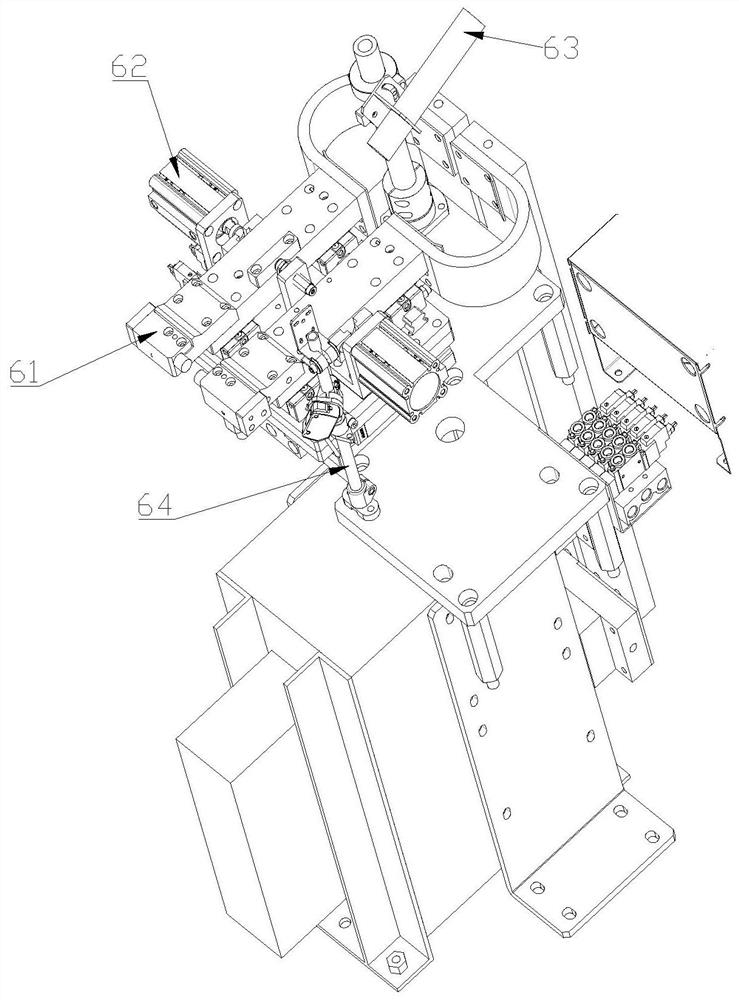

[0027] like figure 1The shown automatic equipment for realizing contact welding includes a frame 1, and a turntable mechanism 2 is provided on the frame 1, and four positioning toolings 3 are arranged in a circular array on the turntable mechanism 2. The tooling 3 rotates together with the turntable mechanism 2. The side of the frame 1 located on the turntable mechanism 2 is sequentially provided with a sheet metal feeding mechanism 4 for feeding sheet metal according to the rotation direction of the turntable mechanism 2. The contact feeding mechanism 5 of the contact, the welding mechanism 6 for welding the sheet metal and the contact together, and the unloading mechanism 7 for unloading the welded product, the turntable mechanism 2 is used to drive the sheet metal The metal is moved to different stations, the sheet metal feeding mechanism 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com