Sewage treatment system and sewage treatment method

A sewage treatment system and water inlet technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of running cost and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

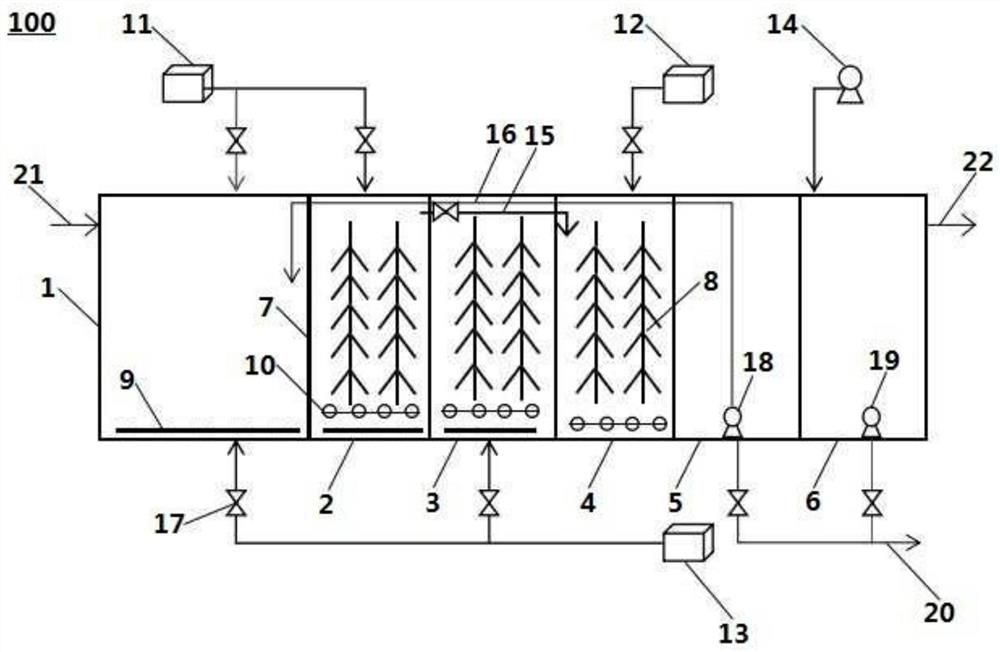

[0033] Such as figure 1 As shown: this embodiment provides a sewage treatment system 100, including reaction pool I1, reaction pool II2, reaction pool III3 and reaction pool IV4 connected in sequence, the reaction pool I1 is provided with a water inlet 21, and the sewage flows by itself after pretreatment Or the pump is extracted to the water inlet 21, the partition plate 7 between the reaction pool I1 and the reaction pool II2 can be disassembled, the reaction pool II2 and the reaction pool IV4 are connected through the connecting pipeline 15, the reaction pool I1 is an anoxic pool, and the reaction pool Ⅱ2 is anoxic pool or aerobic pool, reaction pool Ⅲ3 is anoxic pool or aerobic pool, and reaction pool Ⅳ4 is an aerobic pool. Reaction pool Ⅱ2, reaction pool Ⅲ3, and reaction pool Ⅳ4 are equipped with biological filler 8. Filler 8 is used to hang biofilm, aerobic activated sludge is set in the aerobic tank, anaerobic granular activated sludge is set in the anoxic tank, and nit...

Embodiment 2

[0047] This embodiment provides a sewage treatment method using the sewage treatment system 100 of Embodiment 1, including the following three operating modes:

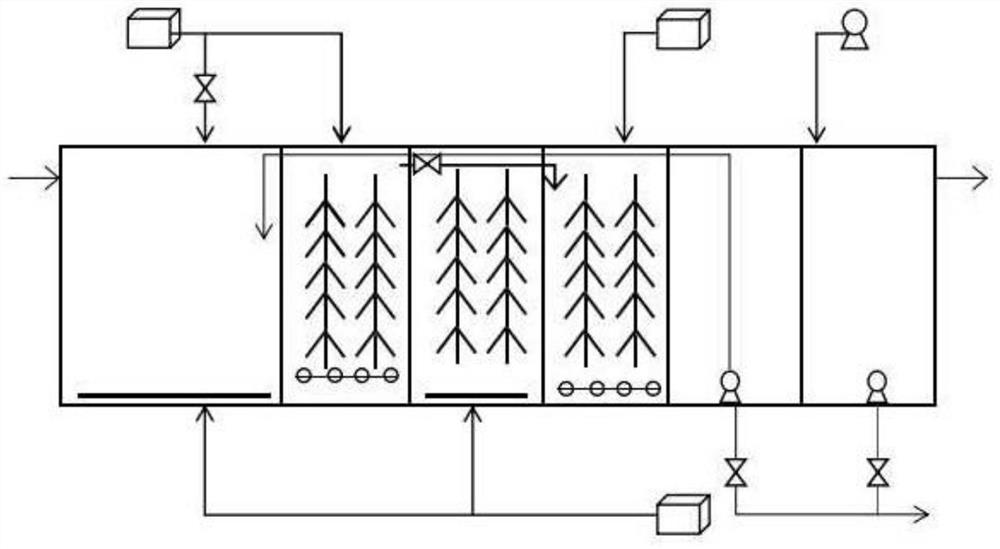

[0048] Such as figure 2 As shown, the high emission standard AO-AO mode: reaction pool Ⅰ1 and reaction pool Ⅲ3 are anoxic pools, reaction pool Ⅱ2 and reaction pool Ⅳ4 are aerobic pools, and the first fan 11, the second fan 12 and the third fan 13 are turned on , the perforated pipe 9 in the reaction tank I1 is opened, the aerator 10 in the reaction tank II2 is opened, the perforated pipe 9 is closed, the perforated pipe 9 in the reaction tank III3 is opened, the aerator 10 is closed, and the aeration in the reaction tank IV4 The device 10 is opened and the perforated pipe 9 is closed, which is used for areas with poor water quality and high water output standards;

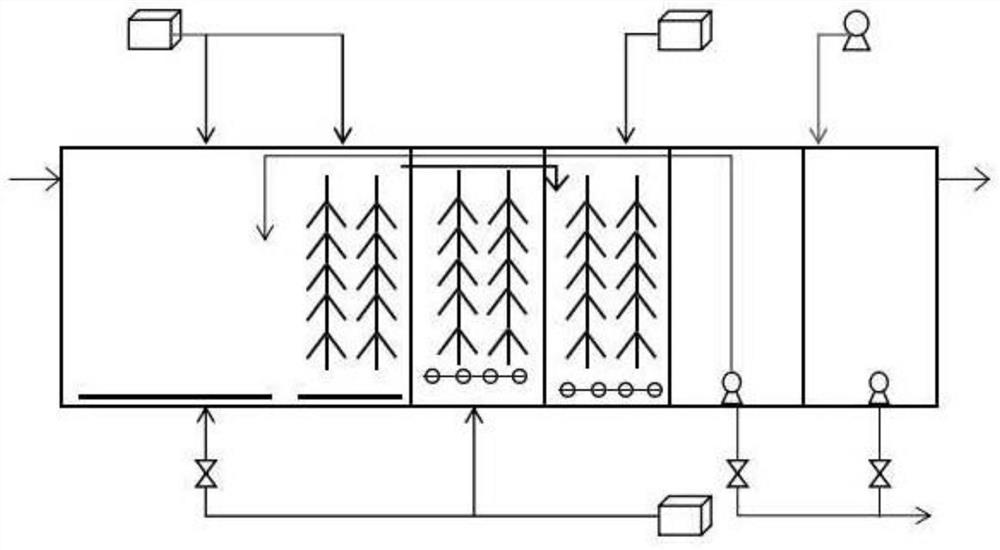

[0049] Such as image 3 As shown, the low emission standard AO mode: remove the partition plate 7 between the reaction pool Ⅰ1 and the reaction pool Ⅱ2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com