Rubber coating with high wear resistance and high hand feeling and preparation method thereof

A rubber coating, high wear resistance technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of loss of rubber elastic touch, inability to have both, and achieve the effect of cost saving, strong skin feeling and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

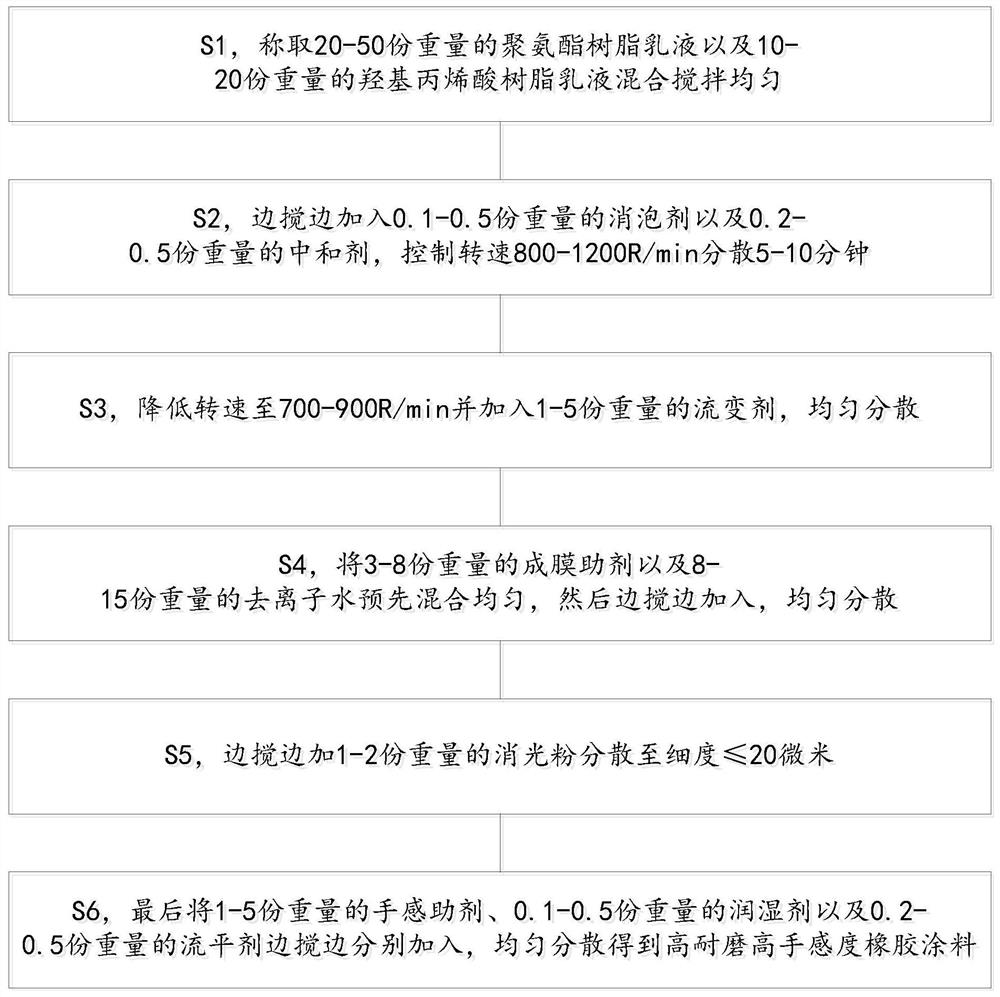

[0023] Please refer to figure 1 , the present invention further provides a method for preparing a high wear-resistant high-hand feeling rubber coating, comprising the following steps:

[0024] S1, taking 20-50 parts by weight of polyurethane resin emulsion and 10-20 parts by weight of hydroxyl acrylic resin emulsion and mixing and stirring evenly;

[0025] S2, add 0.1-0.5 parts by weight of defoamer and 0.2-0.5 parts by weight of neutralizing agent while stirring, and control the speed of 800-1200R / min to disperse for 5-10 minutes;

[0026] S3, reduce the rotational speed to 700-900R / min and add 1-5 parts by weight of rheological agent, and disperse evenly;

[0027] S4, 3-8 parts by weight of film-forming aids and 8-15 parts by weight of deionized water are pre-mixed evenly, and then added while stirring to disperse evenly;

[0028] S5, add 1-2 parts by weight of matting powder while stirring to disperse until the fineness is ≤20 microns;

[0029] S6, finally add 1-5 parts ...

Embodiment 1

[0034] Weigh 40 parts by weight of polyurethane resin emulsion and 15 parts by weight of hydroxyacrylic resin emulsion, mix and stir evenly; add 0.3 parts by weight of defoamer and 0.4 parts by weight of neutralizing agent while stirring, and control the speed of 1100R / min to disperse for 10 minutes ; Reduce rotating speed to 800R / min and add 3 parts of weight of nano-titanium dioxide (not through UV irradiation), evenly disperse; 5 parts of weight of film-forming aid (ethylene glycol monobutyl ether) and 10 parts of weight of deionized water Mix well in advance, then add while stirring, and disperse evenly; add 1 part of matting powder while stirring to disperse until the fineness is ≤ 20 microns; finally add 3 parts by weight of hand feeling aid, 0.3 parts by weight Part by weight of leveling agent is added separately while stirring, and evenly dispersed to obtain a rubber coating with high wear resistance and high hand feeling.

Embodiment 2

[0040] Weigh 40 parts by weight of polyurethane resin emulsion and 15 parts by weight of hydroxyacrylic resin emulsion, mix and stir evenly; add 0.3 parts by weight of defoamer and 0.4 parts by weight of neutralizing agent while stirring, and control the speed of 1100R / min to disperse for 10 minutes Reduce the rotating speed to 800R / min and add 3 parts of weight of nano-titanium dioxide (through UV irradiation for 10 minutes), evenly disperse; 5 parts of weight of film-forming aids and 10 parts of weight of deionized water are pre-mixed, and then stir While adding, disperse evenly; while stirring, add 1 part by weight of matting powder to disperse to fineness ≤ 20 microns; finally add 3 parts by weight of hand feeling additive, 0.3 part by weight of wetting agent and 0.4 part by weight of leveling agent Stirring is added separately, and the rubber coating with high wear resistance and high hand feeling can be obtained by uniform dispersion.

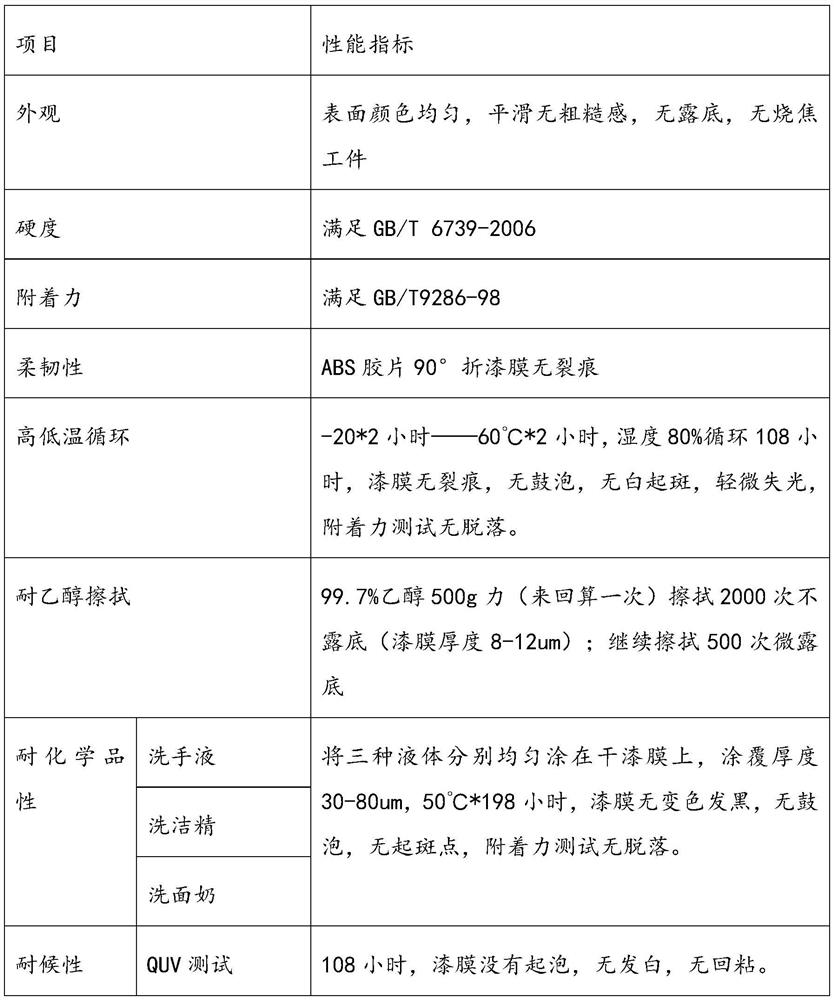

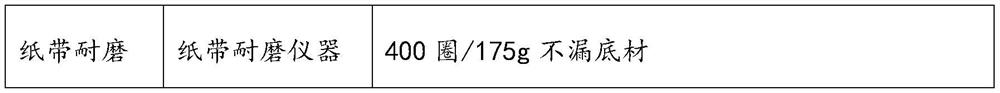

[0041] Test Example: The rubber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com