Optical adhesive with low gel fraction and preparation method thereof

An optical adhesive, low-gel technology, used in adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem of uncontrollable and accurate control of the gel fraction of optical adhesives, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

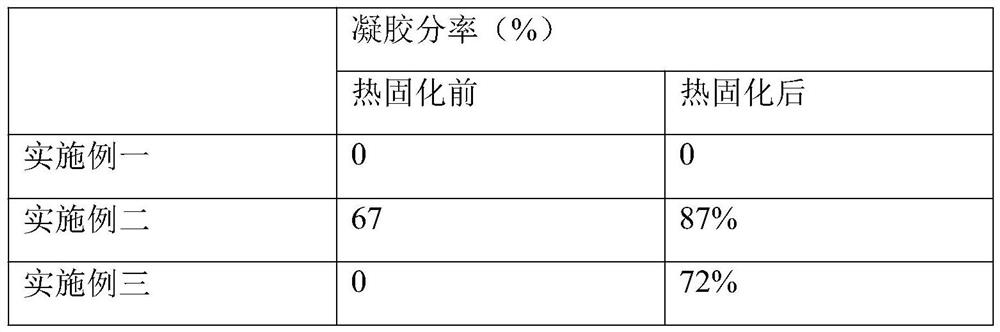

Examples

preparation example Construction

[0013] A method for preparing an optical adhesive with a low gel fraction, comprising the steps of:

[0014] Step 1: Mix 0-80 parts of isooctyl acrylate, 0-30 parts of hydroxyethyl acrylate, 0-15 parts of isobornyl acrylate, 0-5 parts of isocyanate ethyl acrylate and 0-0.5 parts of light The initiator is mixed to obtain an optical prepolymer;

[0015] Step 2: adding 0-1 part of multifunctional monomer to the optical prepolymer obtained in step 1, coating on the base film, and then irradiating with UV light;

[0016] Step 3: irradiating and reacting the coated base film under UV light to obtain an optical adhesive film.

[0017] Step 4: heat the coated optical adhesive film at 40-120°C for 12h-72h to carry out deep curing and cross-linking.

Embodiment 1

[0019] An optical adhesive with a low gel fraction, consisting of the following substances in parts by mass: 80 parts of isooctyl acrylate, 10 parts of hydroxyethyl acrylate, 10 parts of isobornyl acrylate and 0.5 parts of 1-hydroxy - cyclohexylbenzophenone.

[0020] A method for preparing an optical adhesive with a low gel fraction, comprising the steps of:

[0021] Step 1: Mix 80 parts of isooctyl acrylate, 10 parts of hydroxyethyl acrylate, 10 parts of isobornyl acrylate, and 0.5 parts of 1-hydroxy-cyclohexylbenzophenone to obtain an optical prepolymer;

[0022] Step 2: adding 0.2 parts of (2,4,6-trimethylbenzoyl)phenylphosphine oxide into the optical prepolymer, coating on the base film, and then irradiating with UV light;

[0023] Step 3: irradiating the coated base film under UV light, reacting and curing to obtain an optical adhesive film.

[0024] Step 4: heat the coated optical adhesive film at 100° C. for 70 hours to perform deep curing and cross-linking.

Embodiment 2

[0026] An optical adhesive with a low gel fraction, consisting of the following substances in parts by mass: 80 parts of isooctyl acrylate, 10 parts of hydroxyethyl acrylate, 10 parts of isobornyl acrylate, 0.1 part of isocyanate acrylic acid ethyl ester and 0.5 parts of 1-hydroxy-cyclohexylbenzophenone.

[0027] A method for preparing an optical adhesive with a low gel fraction, comprising the steps of:

[0028] Step 1: Mix 80 parts of isooctyl acrylate, 10 parts of hydroxyethyl acrylate, 10 parts of isobornyl acrylate and 0.5 parts of 1-hydroxyl-cyclohexylbenzophenone to obtain a low gel fraction optical adhesive mixture;

[0029] Step 2: Add 0.2 parts by mass of (2,4,6-trimethylbenzoyl) phenylphosphine oxide and 0.05 parts of trimethylolpropane triacrylate into the adhesive, on the base film Coating is carried out, followed by UV light irradiation;

[0030] Step 3: irradiating the coated base film under UV light, reacting and curing to obtain an optical adhesive film.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com