Feed dog driving mechanism of sewing machine and feed dog positioning method

A positioning method and feeding dog technology, applied in the direction of feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of troublesome operation, passive, unable to automatically adjust the needle distance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

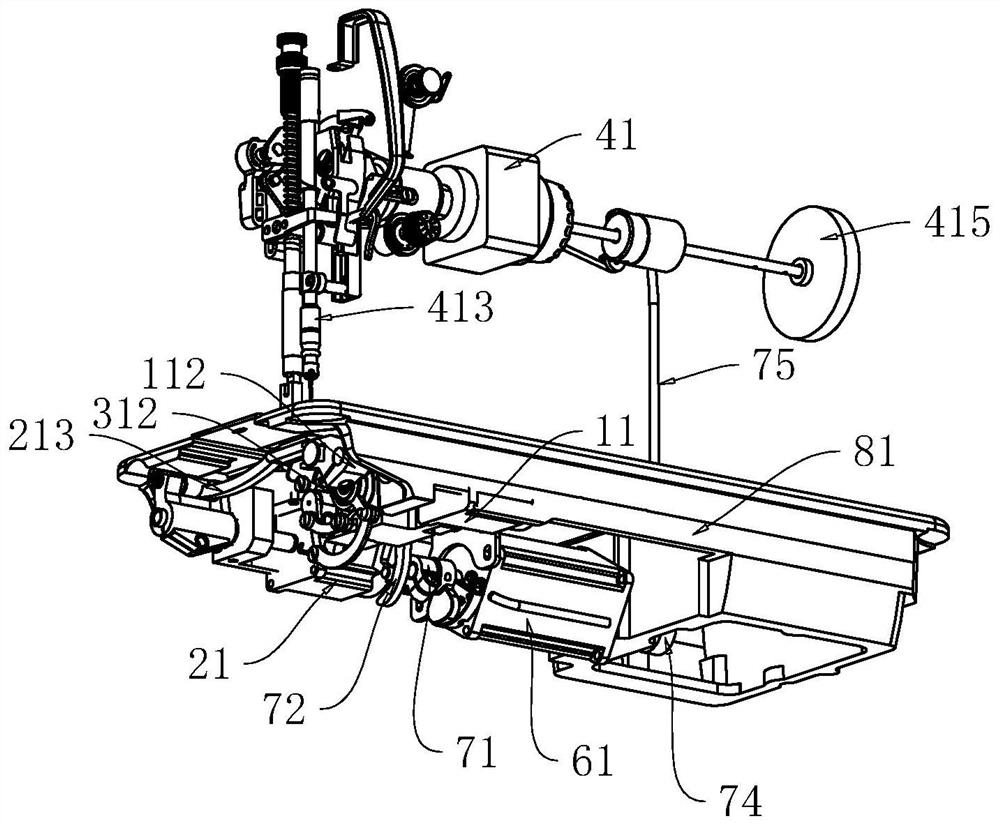

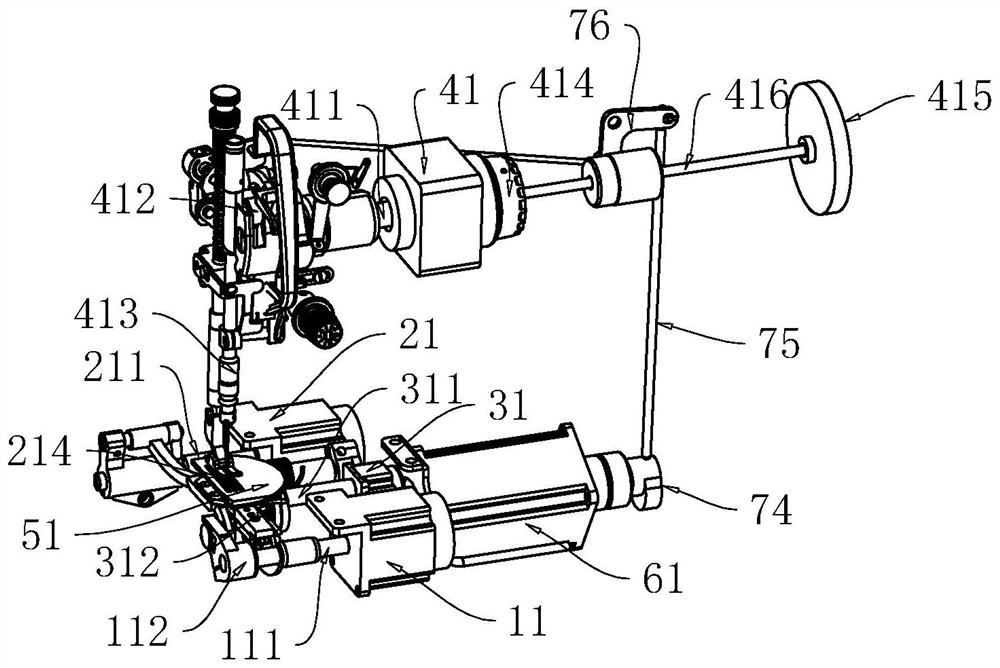

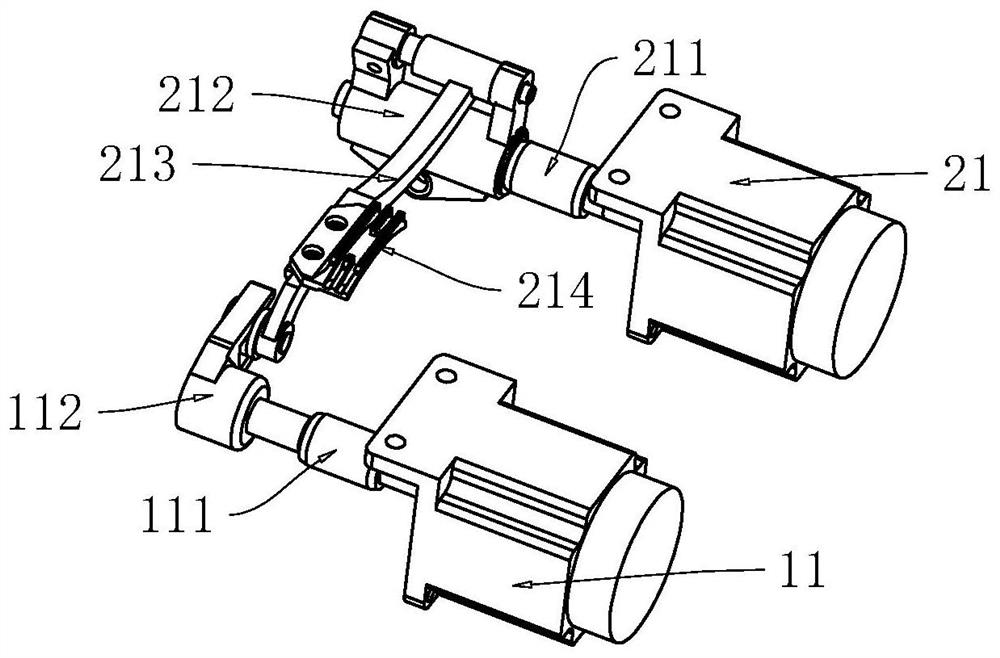

[0027] Attached below Figure 1-7 The preferred embodiments of the present application are described in detail, so that the advantages and features of the present application can be more easily understood by those skilled in the art, so as to make a clearer definition of the protection scope of the present application. These embodiments are only for illustration present invention, rather than limitation of the present invention.

[0028] This application proposes a feeding dog driving mechanism and a feeding dog positioning method of a sewing machine. The sewing machine has a lower thread driving mechanism, an upper thread driving mechanism, a thread trimming and presser foot lifting driving mechanism and a control system. Among them, the bottom thread drive mechanism has a cloth feeding drive assembly and a rotary hook driving assembly. The cloth feeding drive assembly mainly consists of a tooth lifting motor 11, a cloth feeding motor 21, a tooth lifting shaft 111, a cloth fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com