Construction method of cast-in-place steel-concrete composite beam of double-girder longitudinal one-way plate

A one-way slab, cast-in-place steel technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large amount of steel used in steel-concrete composite beams, poor durability of cast-in-place joints, and cumbersome construction process, saving steel and facilitating The effect of repairing and facilitating subsequent repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

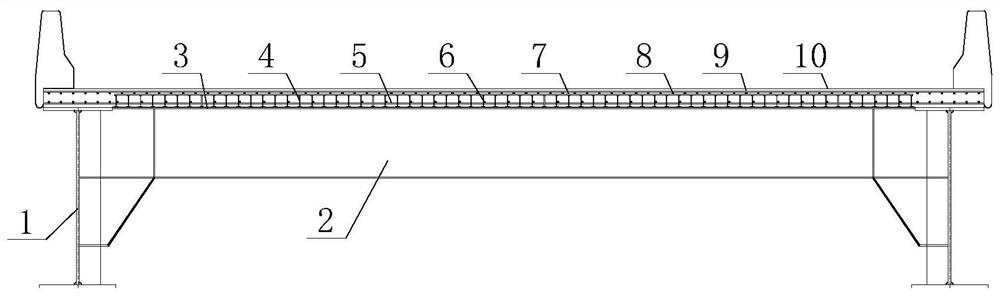

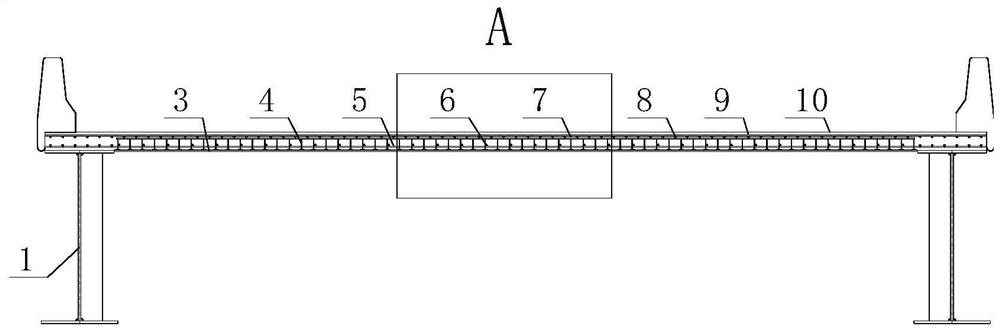

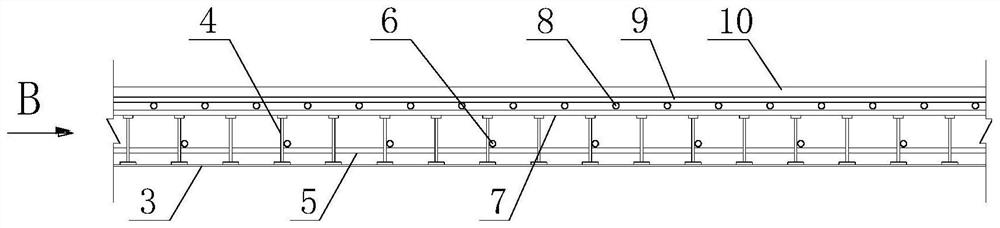

[0038] see Figure 1-5 , a cast-in-place steel-concrete composite beam with double main girder longitudinal one-way slabs, including I-beam main girders 1 on the left and right sides, a steel structure crossbeam 2 between the I-beam main girders 1 on both sides, and two adjacent steel structures A bottom steel plate 3 is arranged between the beams 2, and the PBL shear key small I-beam 4 with longitudinally arranged web openings is fixed on the bottom steel plate 3; the PBL shear key small I-beam 4 of the web There is a transverse shearing reinforcement 5 passing through the hole, and the transverse shearing reinforcement 5 is fixed in the hole of the PBL shear key small I-shaped steel 4 web, and the longitudinal fixing reinforcement 6 is fixed on the transverse shearing reinforcement 5 The upper edge of the small I-beam 4 of the PBL shear key is fixedly provided with a horizontal maintenance steel bar 7, and a longitudinally stressed steel bar 8 is fixedly installed on the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com