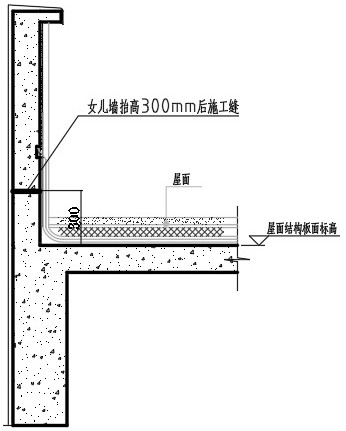

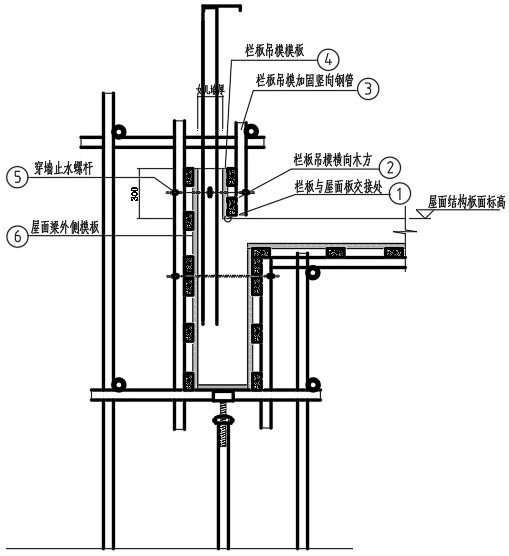

Waterproof construction method for joint of parapet root and roof concrete structure

A technology of concrete structure and construction method, which is applied in the direction of roofing, roof covering, construction components on-site preparation, etc., and can solve problems such as water seepage in construction joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0021] For the waterproof construction method at the junction of the parapet root and the roof concrete structure, the traditional method is to pour the parapet slab after the concrete of the roof beam is poured. There is no self-waterproof effect at the junction of the parapet fence and the roof. The slope of the roof and the drainage direction are all at the edge of the parapet. Long-term rainy or heavy rainwater accumulation often occurs, especially due to construction defects of the waterproof layer or aging of the waterproof layer. Roof water leaks to the insulation layer and the slope layer, resulting in long-term water accumulation on the roof causing water seep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com