System for measuring oil level of oil product and method thereof

A measurement system and oil level technology, which is applied in the direction of measuring devices, liquid/fluid solid measurement, liquid level indicators for physical variable measurement, etc., can solve the problem of not being able to reflect the quality of fuel at the same time, to improve calculation accuracy and improve The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with accompanying drawing:

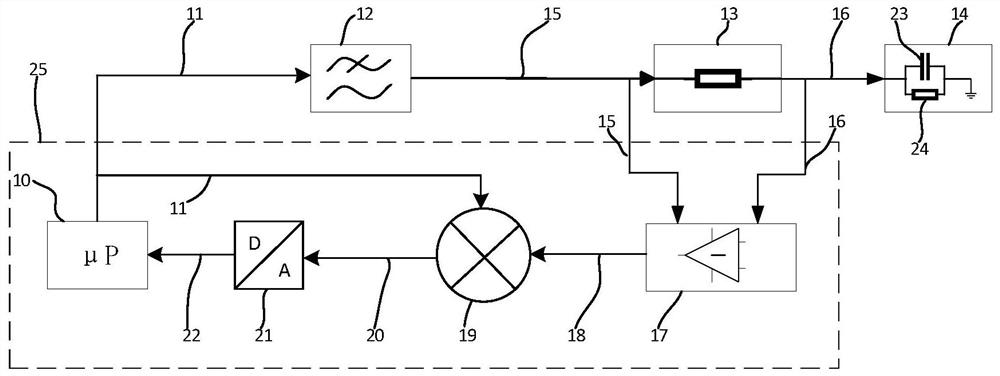

[0028] figure 1 A processor 10 is included in it, wherein the processor 10 sends out a TTL excitation signal 11, and after passing through a low-pass filter 12, it becomes a sinusoidal signal A 15 of the same frequency.

[0029] specific:

[0030] Including processor 10, low-pass filter 12, sampling resistor 13, sensor to be tested 14, differential acquisition processing circuit 17, frequency mixing module 19 and A / D conversion circuit 21; processor 10 is divided into two circuits, one road is connected to the mixer frequency module 19, the other road is connected to low-pass filter 12, sampling resistor 13 and sensor 14 in turn, and sensor 14 is grounded; the two ends of sampling resistor 13 are connected to differential acquisition processing circuit 17, and differential acquisition processing circuit 17 is connected to mixing module 19, mixing The output end of the frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com