Method for preparing leads type high voltage precision ceramics capacitor

A technology of ceramic capacitors and manufacturing methods, which is applied in the direction of capacitor manufacturing, capacitors, fixed capacitors, etc., and can solve the problems of difficult control of delivery time, waste of materials, and difficulty in grasping the precision of capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The detailed description is as follows, and the preferred embodiments are only for illustration but not for limiting the present invention.

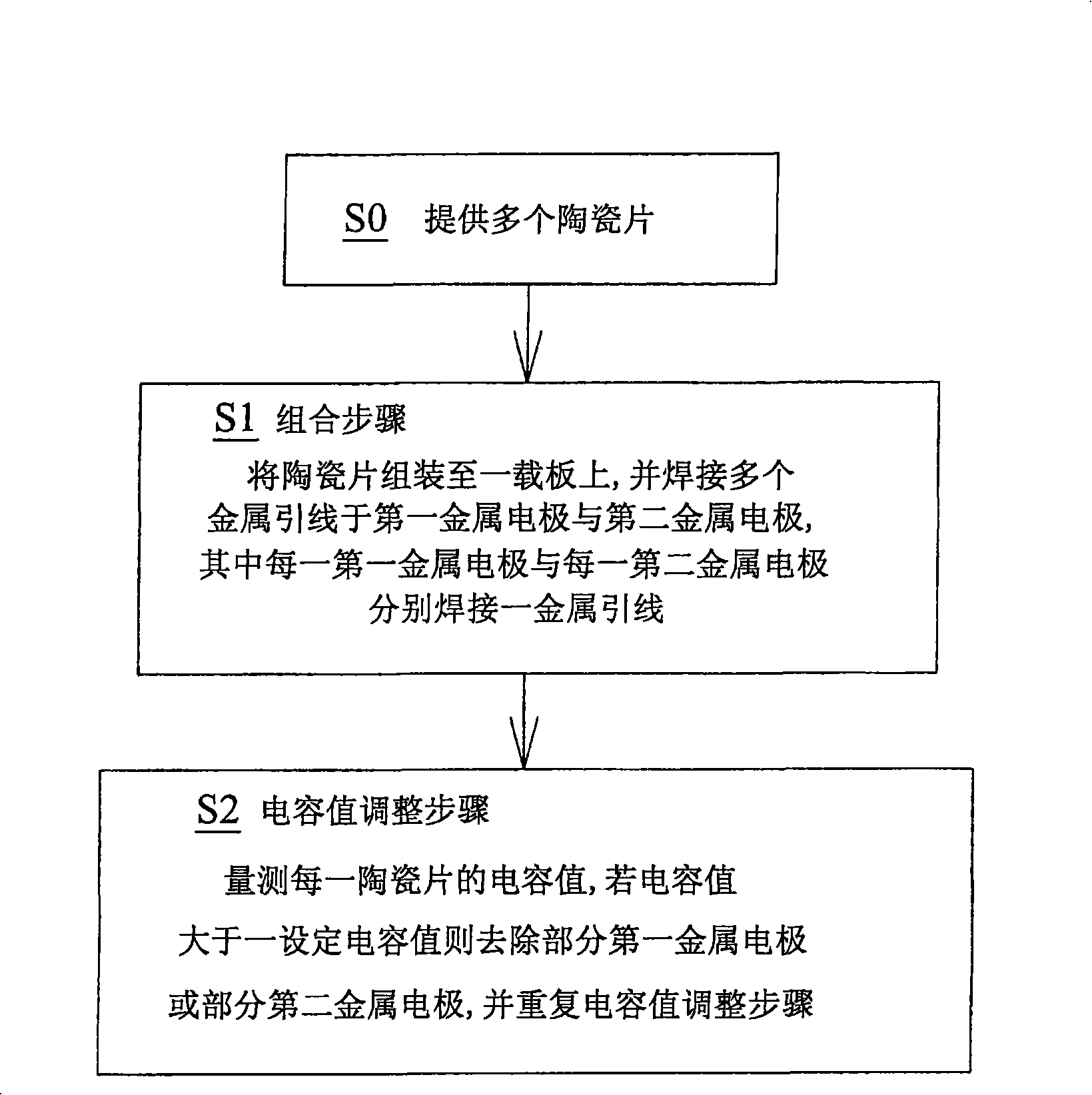

[0032] figure 1 It is a flow chart of the steps of the method for manufacturing a leaded ceramic capacitor according to an embodiment of the present invention, Figure 2a to Figure 2d It is a schematic diagram of each step of the method for manufacturing a leaded ceramic capacitor according to an embodiment of the present invention; please refer to the drawings, the method for manufacturing a leaded ceramic capacitor according to an embodiment of the present invention includes:

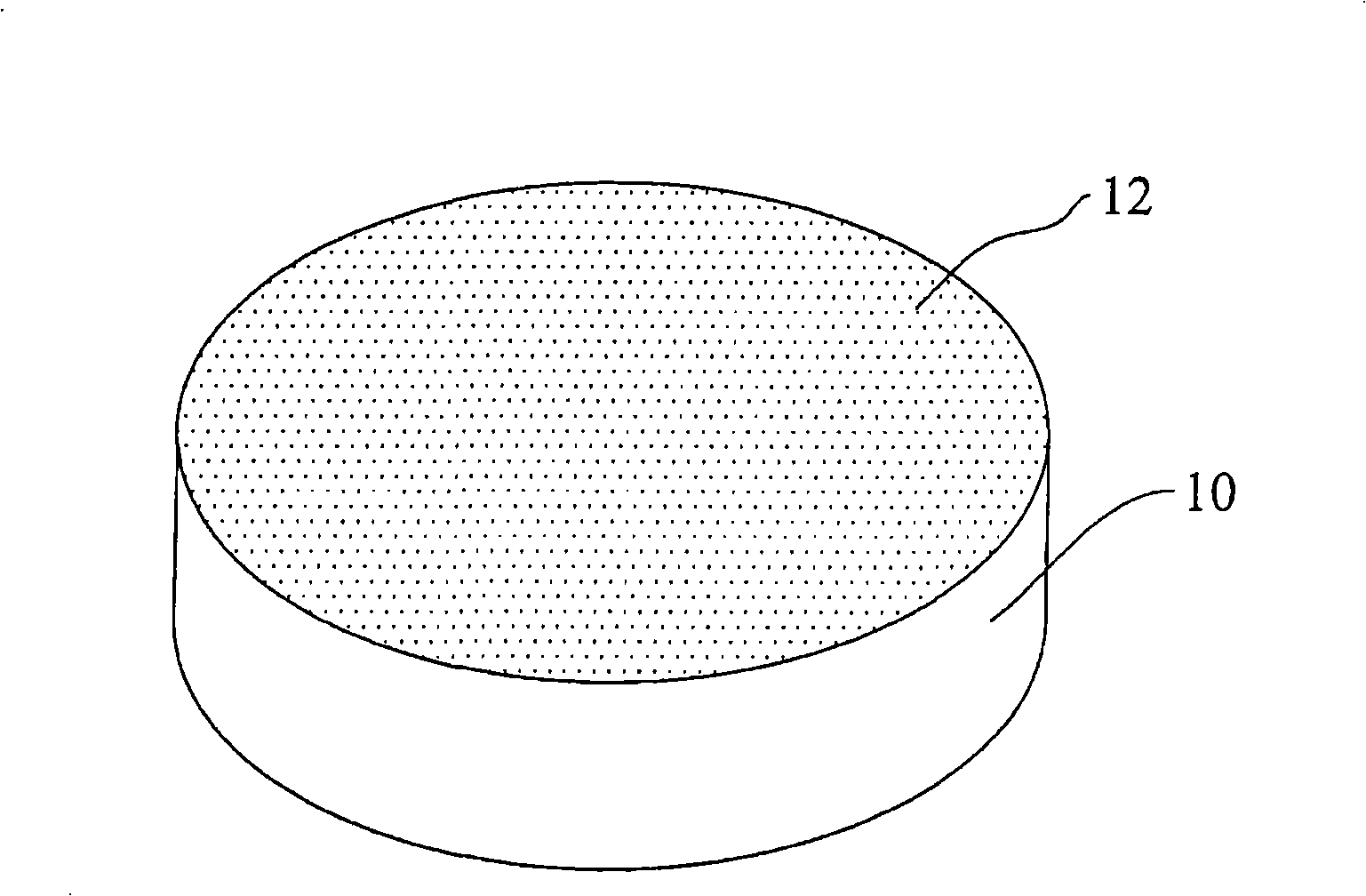

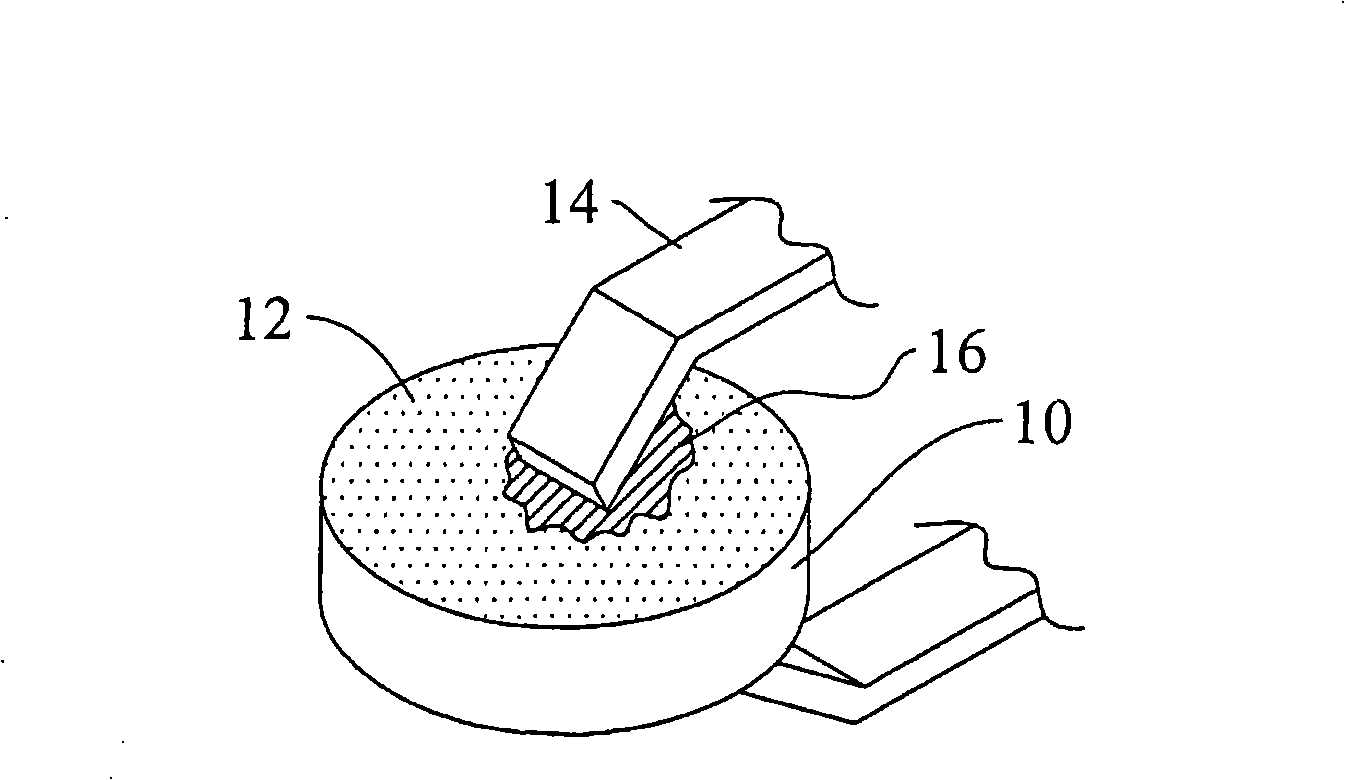

[0033] 1.S0 provides multiple ceramic sheets 10 (please refer to figure 1 and Figure 2a ),like Figure 2a As shown, the ceramic sheet 10 has been shaped, sintered and formed metal electrodes, an upper surface of each ceramic sheet 10 has a first metal electrode 12, and a lower surface of each ceramic sheet 10 has a second metal electrode (in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com