Online detection method for external characteristics of in-service pneumatic stop valve based on pulse excitation

A pneumatic stop valve and pulse excitation technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of hidden failures that cannot be discovered in time, cannot be known, and reduce system security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

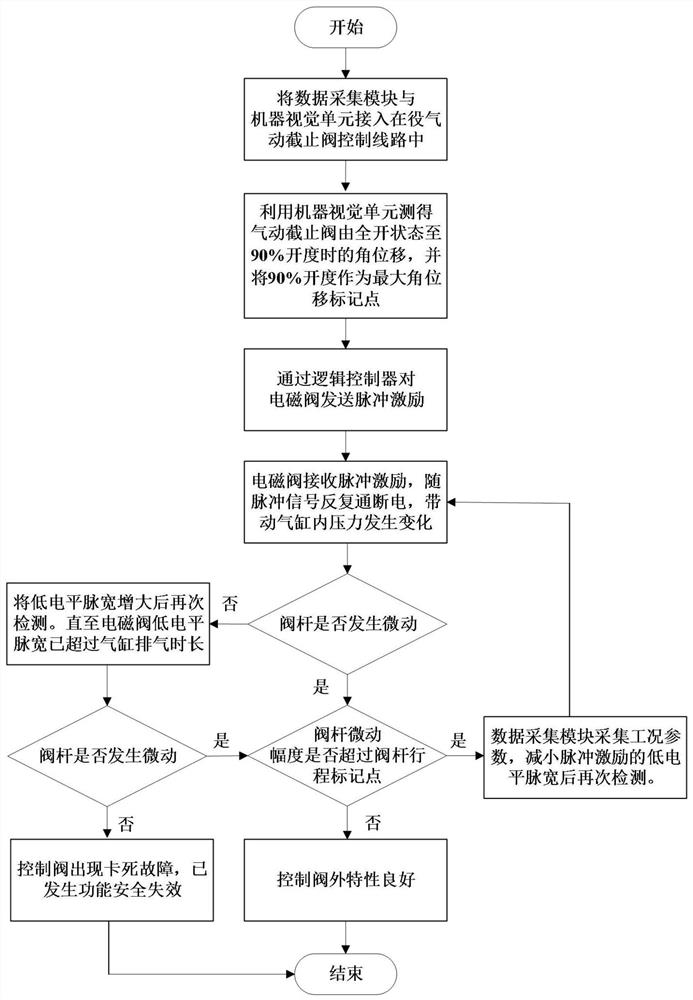

Method used

Image

Examples

Embodiment

[0021] In this embodiment, a pneumatic globe valve with a valve closing time of 5s in a petrochemical enterprise is taken as the object to be tested, and the online detection system for the external characteristics of the in-service pneumatic globe valve based on pulse excitation is tested using the LabVIEW platform and the SIMATIC STEP 7 platform. Software programs are developed and written.

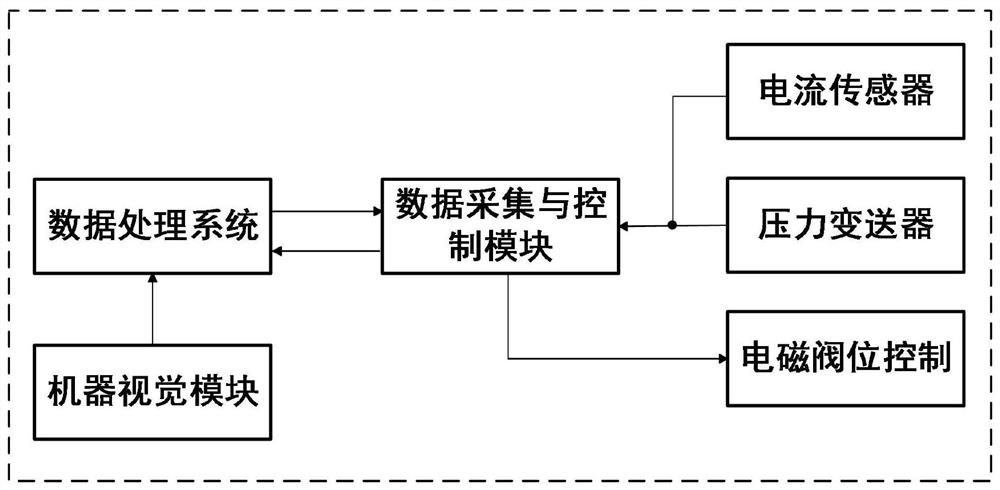

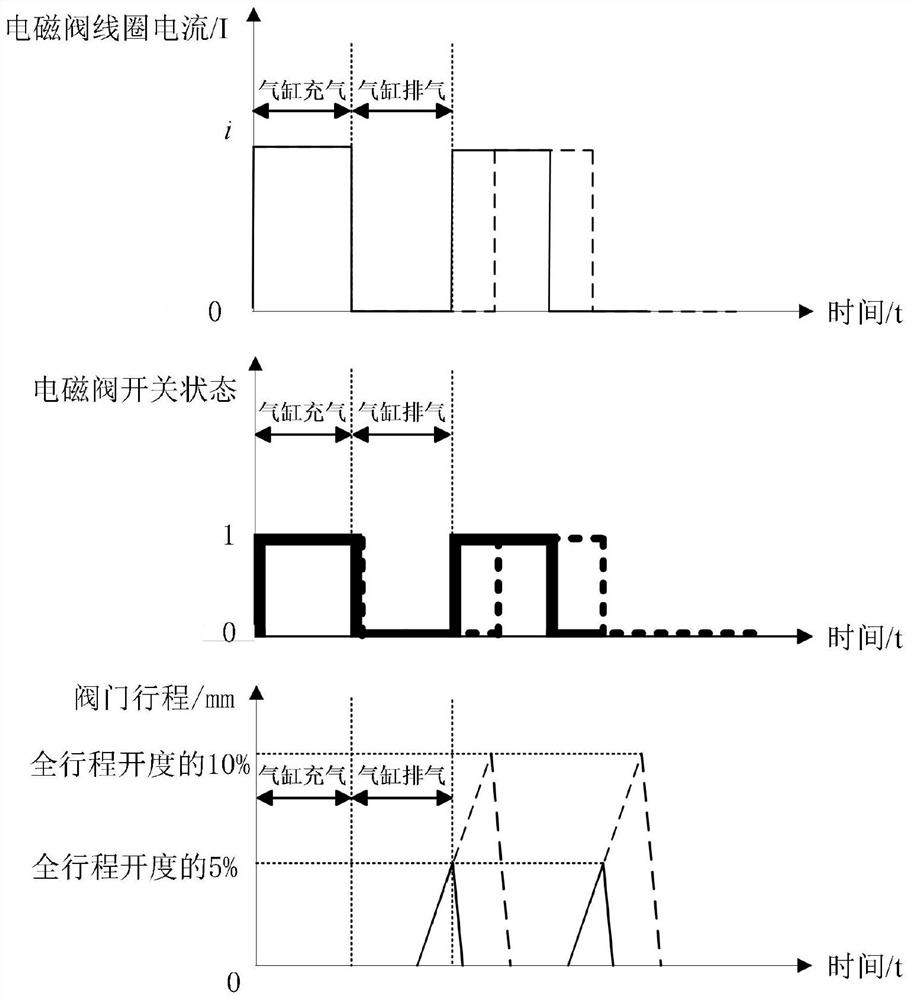

[0022] The current sensor and the pressure transmitter respectively measure the real-time change value of the solenoid valve coil current and the cylinder pressure, and transmit the output signal to the data acquisition module; the data acquisition module controls the power on and off of the solenoid valve by sending high and low levels to the solenoid valve state. The data acquisition module converts all the collected analog and digital signals into 4-20mA output signals and then transmits them to the PC-based data processing system. The data processing system records, analyzes and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com