Horizontal lead-acid storage battery formation method

A technology of lead-acid battery and formation method, which is applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., and can solve the problems of low formation efficiency, long formation time, and difficulty in confirming the density of electrolyte, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

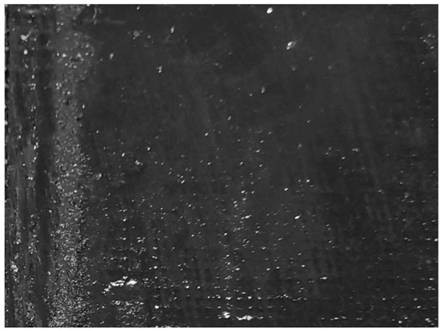

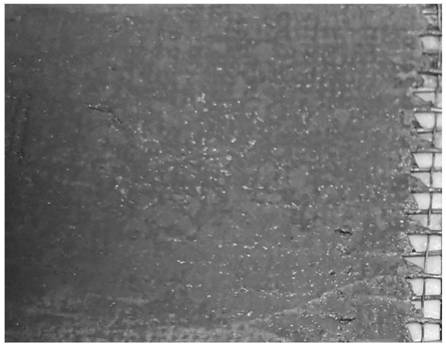

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

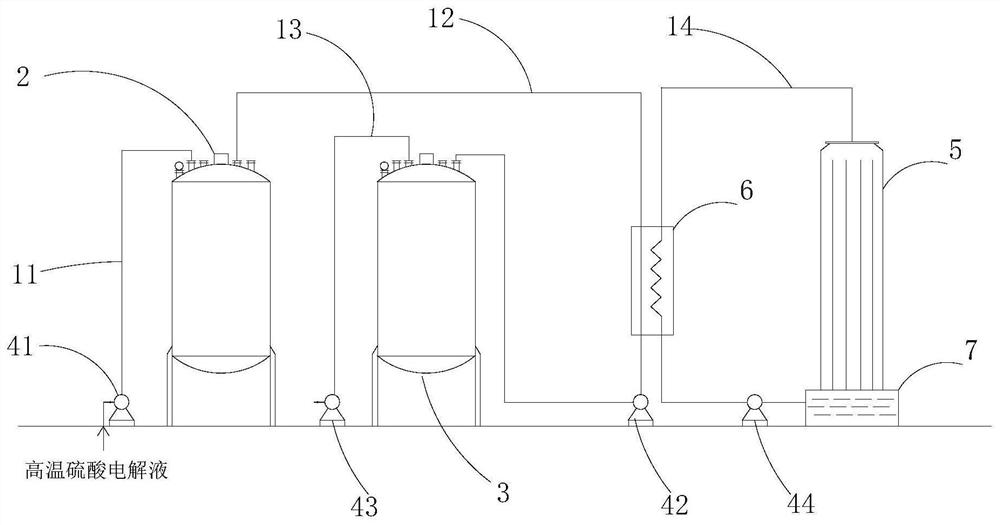

[0044] The present invention will be described in further detail below in conjunction with specific examples.

[0045] A method for forming a horizontal lead-acid storage battery, comprising the steps of:

[0046] Step 1, inject the density of 1.1g / cm into the battery through the filling hole 3 Dilute sulfuric acid is used as the electrolyte, and the temperature of the electrolyte is 10°C;

[0047] Step 2, carry out formation as follows:

[0048] In the first stage, after charging for 5 hours with a charging current of 0.1C, discharge with a discharge current of 0.05C for 0.5 hours; the charging time in the first stage is 0.5CAh, and the discharge capacity is 0.025CAh;

[0049] In the second stage, after charging for 5 hours with a charging current of 0.15C, discharge with a discharge current of 0.075C for 0.5 hours;

[0050] In the third stage, after charging for 4 hours with a charging current of 0.2C, discharge with a discharge current of 0.1C for 0.5 hours; in the third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com