Modified diaphragm, and preparation method and application thereof

A diaphragm and modification technology, applied in the direction of optical devices, instruments, structural parts, etc., can solve the problem of inability to judge the coating coating on the diaphragm surface, and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

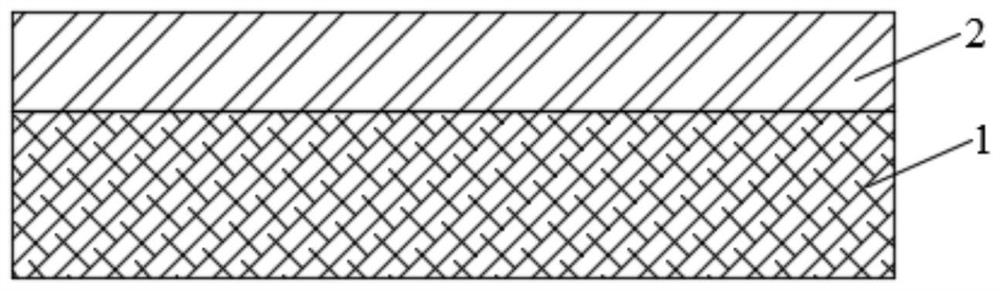

[0044] Such as figure 1 As shown, a modified diaphragm includes a base film 1 and a modified layer 2; the modified layer 2 is coated on at least one surface of the base film 1; wherein the modified layer 2 includes a transparent modifier and a carbon dioxide Manganese, the content of manganese dioxide is 0.5mg / mL~5mg / mL.

[0045] Further, the manganese dioxide is prepared by a hydrothermal method, the reaction temperature is 100-180° C., and the reaction time is 5-20 hours. More preferably, the reaction temperature may be 100-110°C, 110-120°C, 120-130°C, 130-140°C, 140-150°C, 150-160°C, or 170-180°C; and the reaction time may be 5 ~6h, 6~8h, 8~10h, 10~12h, 12~14h, 14~16h, or 16~20h. In the preparation of hydrothermal method, the temperature and time of hydrothermal reaction have a great influence on the morphology and particle size of manganese dioxide. Although the reaction temperature is too high, the formation of manganese dioxide nanosheet morphology will be accelerated,...

Embodiment 2

[0075] A method for characterizing the coating uniformity of the diaphragm, which uses a CCD camera to detect the modified diaphragm described in Example 1, and detects the difference in color to characterize the uniformity of the coating of the modified layer 2 in the modified diaphragm sex.

Embodiment 3

[0077] A lithium ion battery, comprising a positive electrode sheet, a negative electrode sheet and a diaphragm spaced between the positive electrode sheet and the negative electrode sheet, the diaphragm is the modified diaphragm described in Example 1.

[0078] Wherein, the active material layer coated on the positive electrode sheet can include but not limited to chemical formula such as Li a Ni x co y mz o 2- b N b (wherein 0.95≤a≤1.2, x>0, y≥0, z≥0, and x+y+z=1, 0≤b≤1, M is selected from one or more combinations of Mn and Al , N is selected from the combination of one or more of F, P, S), the combination of one or more of the compounds shown, the positive active material can also include but not limited to LiCoO 2 , LiNiO 2 、LiVO 2 , LiCrO 2 , LiMn 2 o 4 、LiCoMnO 4 , Li 2 NiMn 3 o 8 、LiNi 0.5 mn 1.5 o 4 、LiCoPO 4 、LiMnPO 4 、LiFePO 4 、LiNiPO 4 、LiCoFSO 4 、CuS 2 , FeS 2 、MoS 2 , NiS, TiS 2 One or more combinations of these. The positive active mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com