Pipeline scale cleaning sledge

A pipe and casing technology, applied in the field of cleaning equipment, can solve the problems of pollution work efficiency, cleaner stuck in the pipe, incomplete cleaning and descaling, etc., and achieve the effect of high electrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

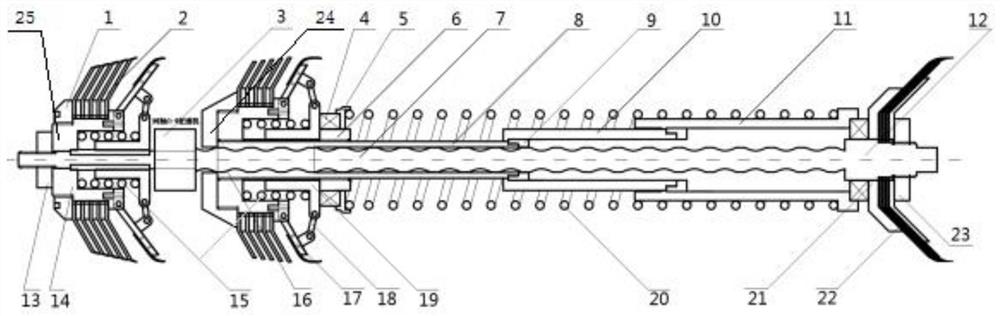

Embodiment 1

[0026] refer to Figure 7 , the ball-reed 22 of the ball-12 cleaning ball is in cavitation phenomenon, the ball-12 is a bowl-shaped cleaning ball head, multi-layer ball-reed 22 and rubber lining, multi-piece, staggered, stacked arrangement, for Choose different R cleaning ball heads for pipes with different diameters. Under the action of high-pressure water on the cleaning ball head, the pressure head makes the rubber lining stick to the reed, and the reed is stretched to obtain a larger R (approximately equal to the inner diameter of the pipe); the interleaved reed and lining make the high-pressure water discharge The surface is very small, and a huge pressure difference is formed between the front and back of the ball head. The high-pressure water flow rushes toward the front of the cleaning ball device along the tiny gap, and a large number of high-speed air bubbles and swirl flow are generated at the front end, and cavitation is formed locally on the pipe wall. High-frequ...

Embodiment 2

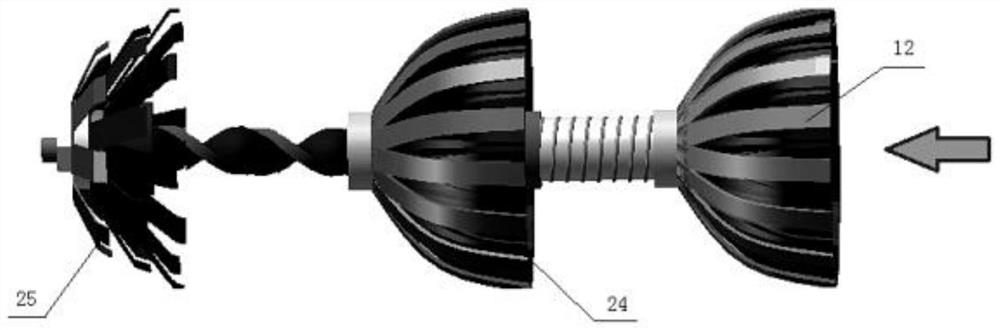

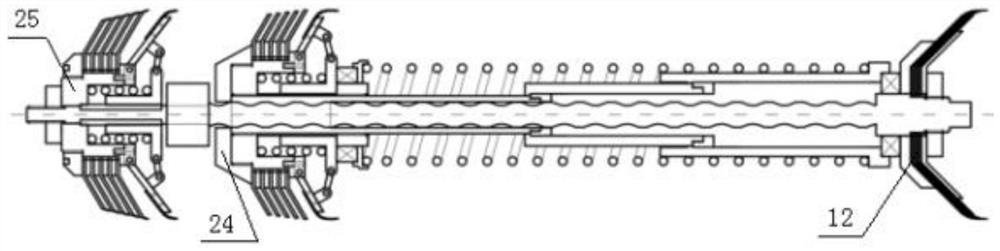

[0029] The interactive force between ball three 25 and ball two 24 produces rotary cutting.

[0030]When the pipeline is slightly or moderately fouled, the thickness of the scale is not enough to make the ball 24 be "stuck". Since the rigidity of the reed of the ball 24 cutter head and the spring force of the supporting and retracting mechanism are stronger than the ball 3, so The bonding force between the ball 2 cutter head reed and the inner wall of the pipe is stronger than that of the ball 3 25 cutter head reed and the inner wall of the pipe, resulting in the friction force of the ball 2 24 cutter head reed acting on the scale on the pipe wall is stronger than that of the ball 3 Cutter head reed acts on the frictional force (resistance when ball two 24 advances is greater than ball three 25) on the tube wall scale. Therefore, when the pulse flow acts on ball one 12, the compressed distance between ball one 12 and ball two 24 becomes shorter; the distance between ball three...

Embodiment 3

[0039] refer to image 3 , Figure 4 , Figure 5 and Figure 6 The rigidity of the reed on the ball 2 and the elastic force of the inner spring of the retracting mechanism are stronger than that of the ball 3. It is most likely to be stuck when the inner wall of the pipe is seriously fouled. When the ball 24 is stuck, the ball 24 can be used as a A fixed fulcrum drives ball three 25 to rotate and displace when ball one 12 pushes forward, and reciprocates multiple times to rotate and scrape the scale layer of ball two 24 front end pipes. After many times of rotating and scraping, it is still impossible to make the ball two 24 pass through the pipeline blockage, then increase the output of the pump, so that the pressure acting on the ball one 12 continues to increase. When the pressure value is greater than the spring compression force in the retracting mechanism, The inner spring of the retracting mechanism continues to be compressed, and the keel of the retracting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com