An engine ball head ball socket automatic press machine

A technology for a press-fitting machine and an engine, applied in the field of press-fitting machines, can solve the problems of high safety risks in manual press-fitting, and achieve the effects of reducing operating costs and risks, improving press-fitting efficiency, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

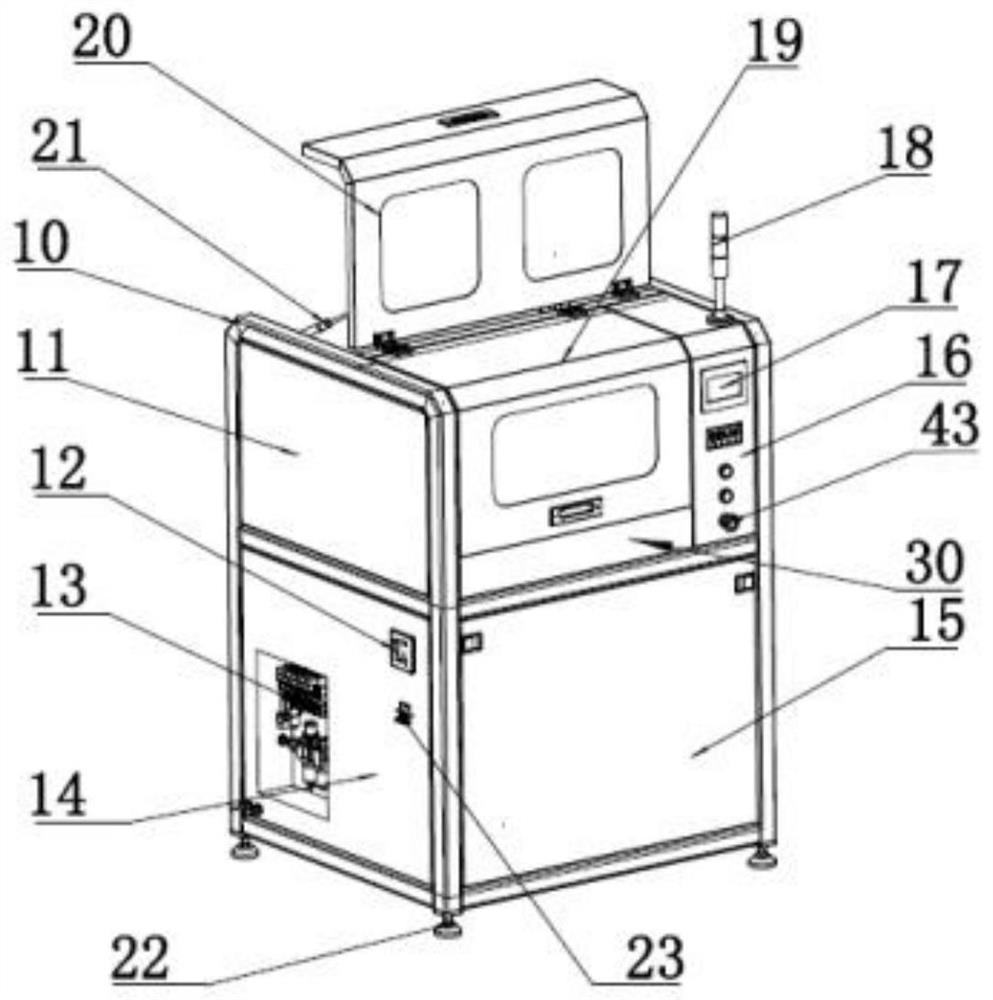

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

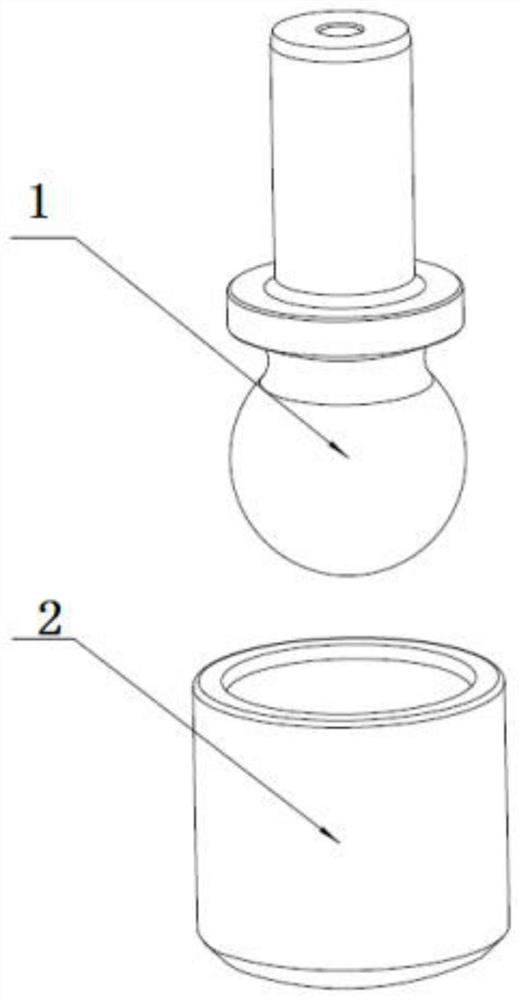

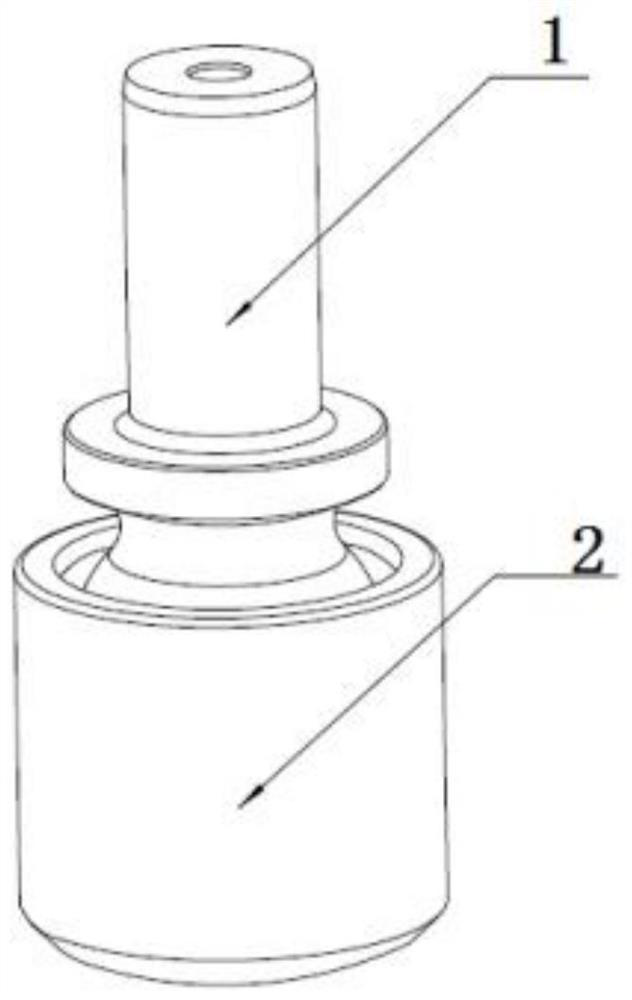

[0033] refer to Figure 1-11 , an engine ball head ball socket automatic pressing machine, including equipment steel frame 10, side cover A11, light switch socket 12, solenoid valve island 13, electrical cabinet side cover A14, electrical cabinet front cover 15, front door side plate Door 16, touch screen 17, alarm 18, equipment front door 19, vibrating plate cover door 20, hydraulic support rod 21, foot 22, main power switch 23, side cover B24, ventilation fan 25, electrical cabinet side cover B26, Defective product box 27, rear cover A 28, rear cover B29, front door baffle 30, control button 43, pressing mechanism 3, ball head feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com