Self-adaptive angle steel clamping assembly with obstacle avoidance function

An adaptive, clamping component technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of long inspection period, high risk of climbing, low work efficiency, etc., and achieve high work reliability and stability , Small and compact size, reliable force sealing and shape sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

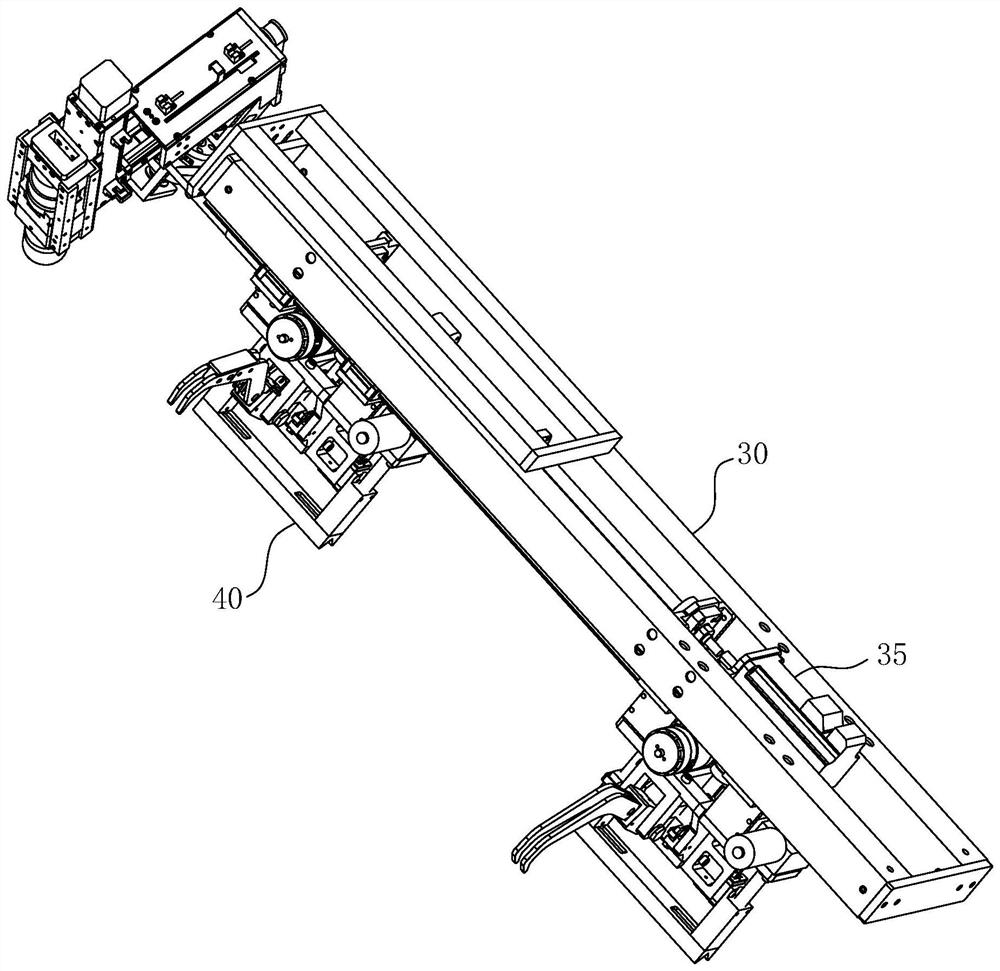

[0052] For the convenience of overall understanding, the structure and working method of the specific embodiment of the whole climbing robot applied in the present invention are described as follows:

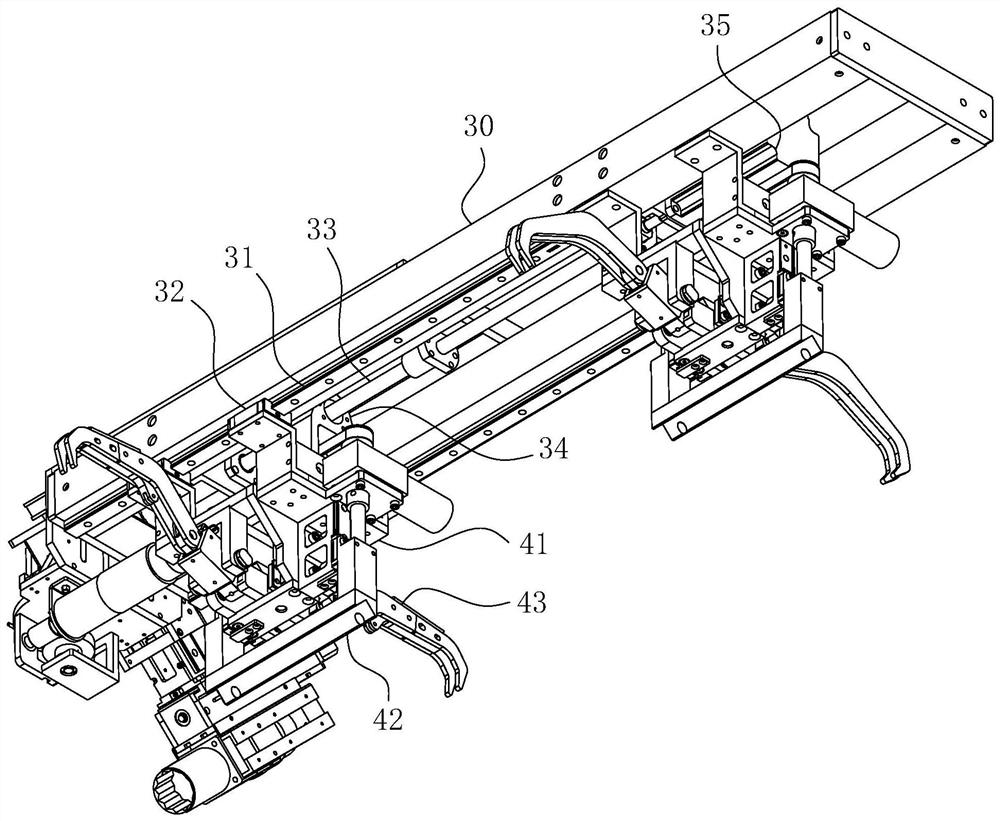

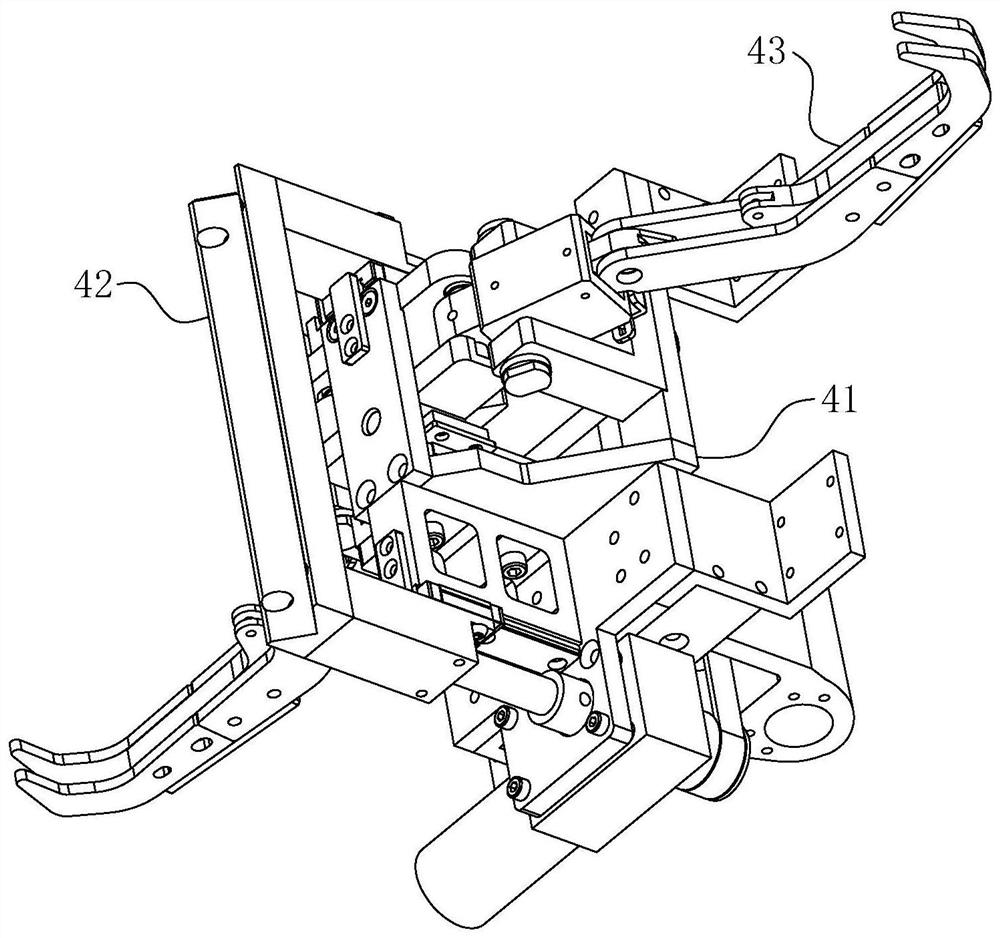

[0053] Climbing robot, here as Figure 1-2 The shown inchworm structure is taken as an example: its specific structure includes a strip-shaped frame-shaped main frame 30, a running part is arranged at the main frame 30 to realize the climbing function relative to the main material of the angle steel, and a working kit is arranged on the main frame 30 to realize the designated function. Maintenance purpose. During actual work, the length direction of the host machine 30 should be parallel to the length direction of the angle steel main material.

[0054] When further designing, still take the inchworm structure as an example: the main frame 30 is arranged with a slide track 31 on the side facing the angle steel main material, and the slide track 31 is provided with a slide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com