Fixing structure used for eliminating accidental cable joint faults of textile machinery electronic control system

An electronic control system and unexpected failure technology, applied in electrical components and other directions, can solve problems such as prolonged maintenance time, difficulty, and shedding, and achieve the effects of improving work reliability and stability, reducing failure rates, and shortening length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

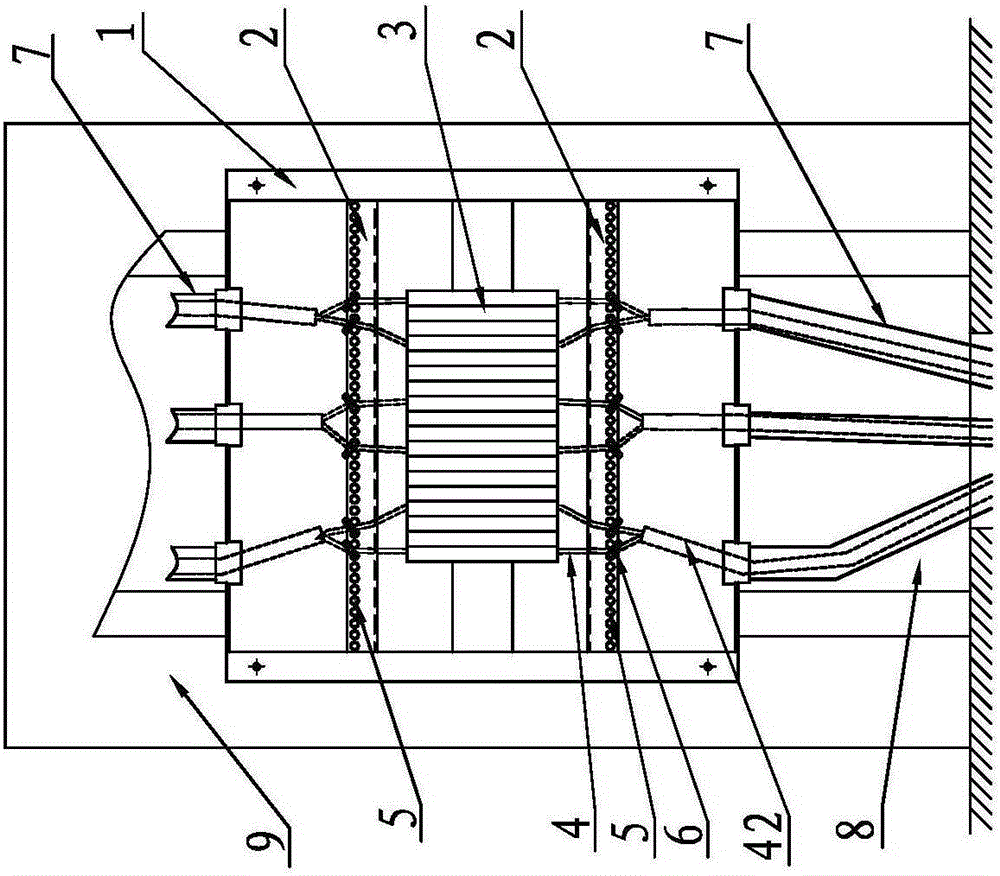

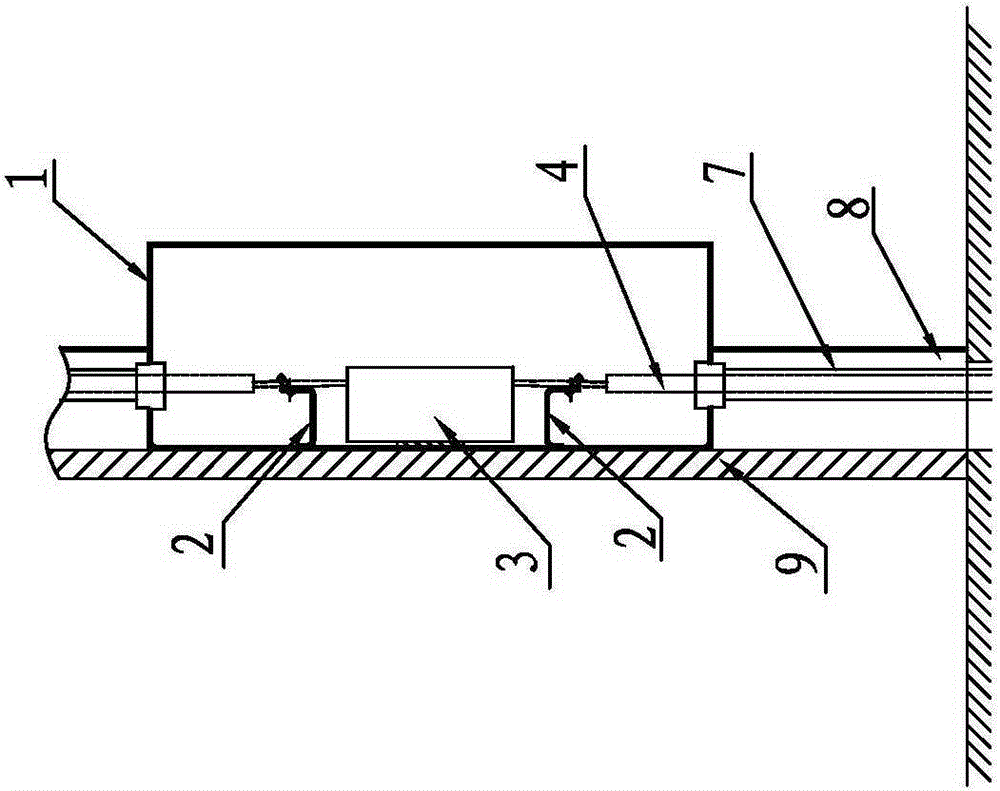

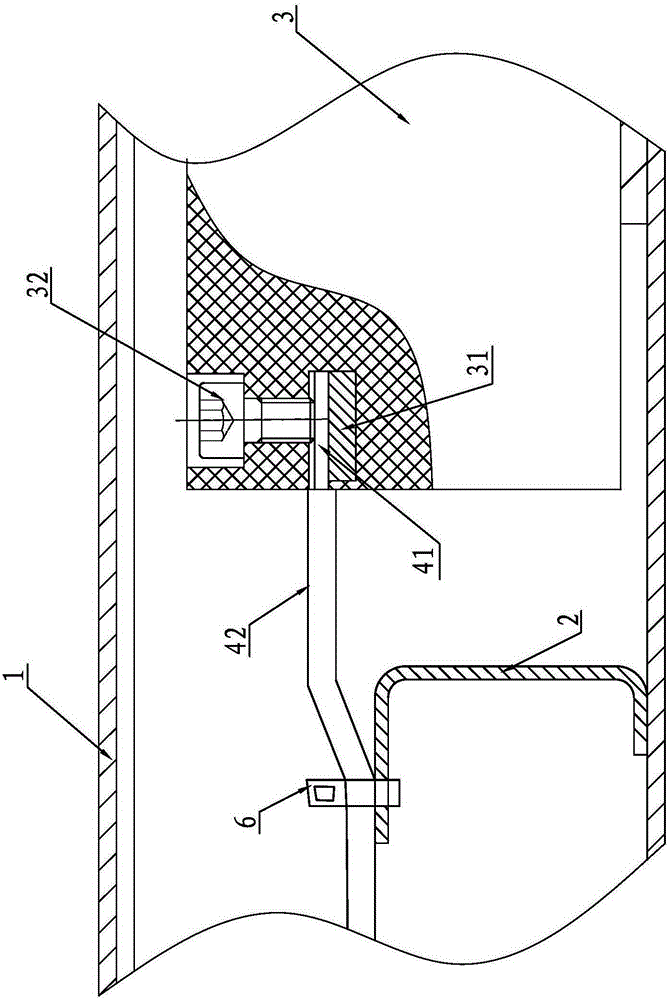

[0020] A fixed structure to eliminate accidental failure of thread joints in electrical control systems of textile machinery, such as Figure 1~4 As shown, it includes an electrical cabinet 1, a wire fixing rod 2, an electrical wiring seat 3, a control wire 4, a fixing hole 5 and a self-locking tightening tie 6, the electrical wiring base 3 is installed in the electrical cabinet 1, and the wire fixing rod 2. Fixed on the side of the electrical cabinet 1, the wiring metal core 41 of the terminal of the control wire 4 is installed on the wiring clip 31 of the electrical wiring seat 3, pressed by the pressure screw 32, on the wire fixing rod 2 along the length direction Fixing holes 5 are arranged at equal intervals, and self-locking tightening tie 6 is worn in the fixing hole 5 corresponding to the position of control thread 4, and the insulating sheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com