On-line monitoring device and monitoring method for furnace temperature of motor iron core heat treatment tunnel furnace

A monitoring device and tunnel furnace technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problem that the production process cannot be monitored online, and achieve the effect of reuse, real-time diagnosis, and guarantee of final performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the present invention, it is to be understood that the term "length"; "width"; "upper"; "lower"; "before"; "left"; "right"; "horizontal" "" Top ";" bottom "" inside ";" outside ";" clockwise ";" counterclockwise ";" axial ";" flat direction ";" circumference "orientation is based on The orientation or positional relationship shown in the drawings is intended to facilitate the description of the present invention and simplified description, rather than indicating or implying that the device or component must have a specific orientation; in a specific directional configuration and operation, it cannot be understood as Restrictions on the invention.

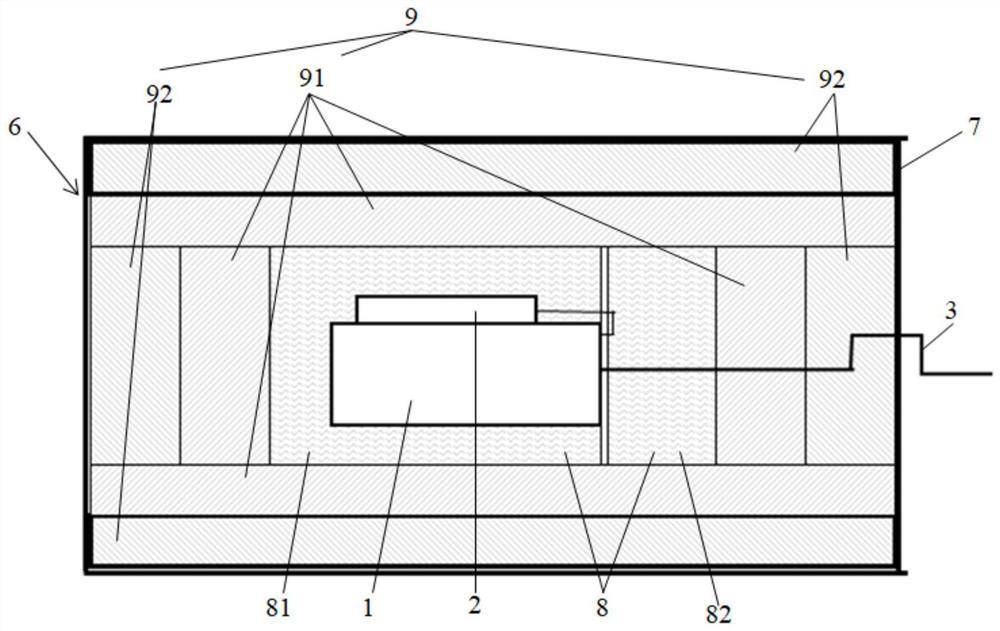

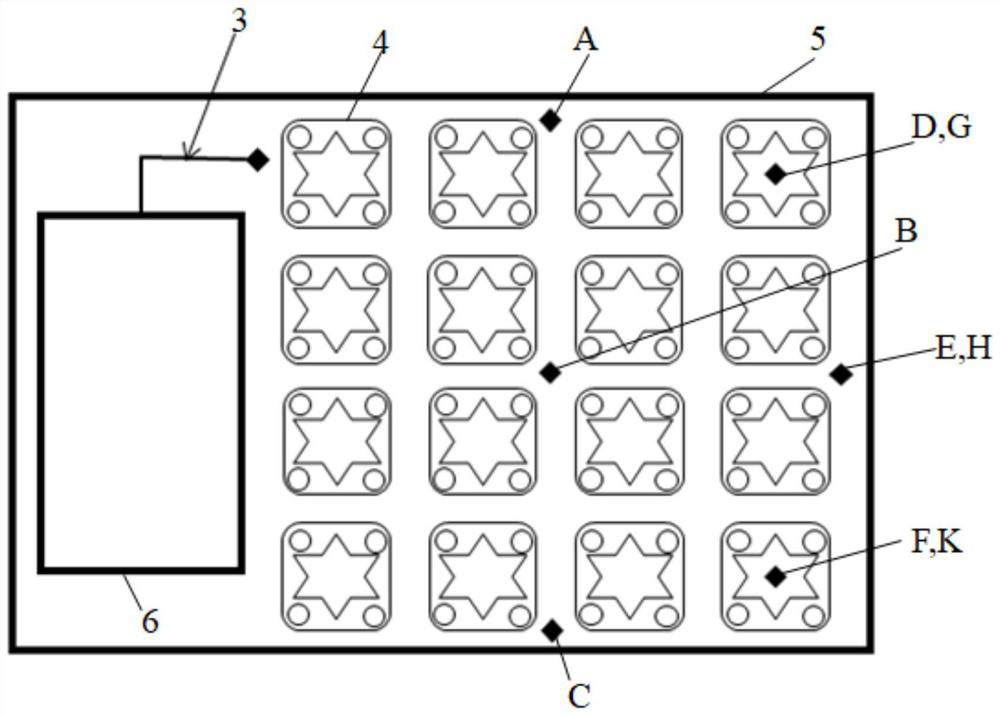

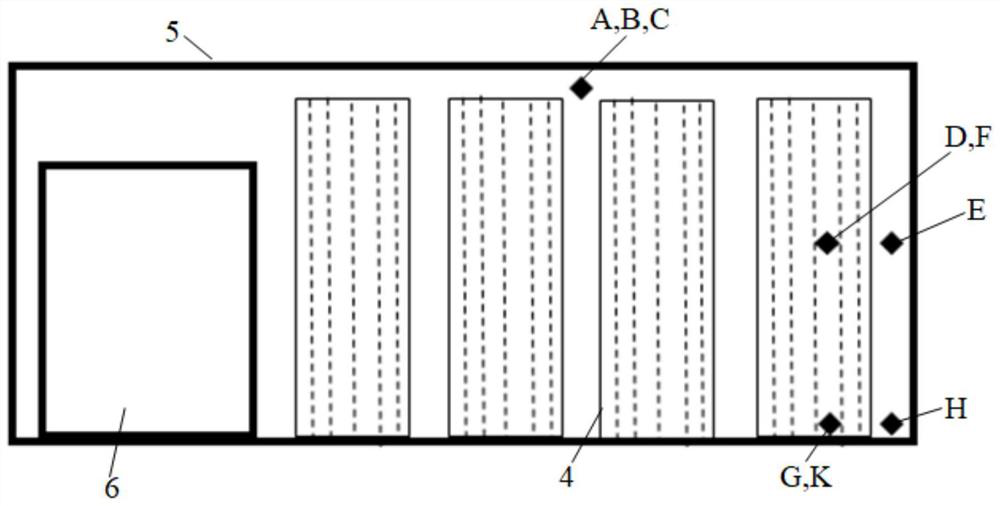

[0035] like Figure 1 to 4 As shown, a motor core heat treatment tunnel furnace furnace temperature online monitoring device includes a temperature measuring mechanism 6 and a frame 5 for placing the motor core 4, the motor core 4 is placed in the material frame 5 In the middle, the temperature measuring mechanism is placed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com