Medium isolation type pressure sensor and manufacturing method thereof

A pressure sensor and medium isolation technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of inability to miniaturize, expensive, difficult mass packaging and calibration testing, etc., to achieve reliability, improve performance, The effect of balancing measurement accuracy and support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

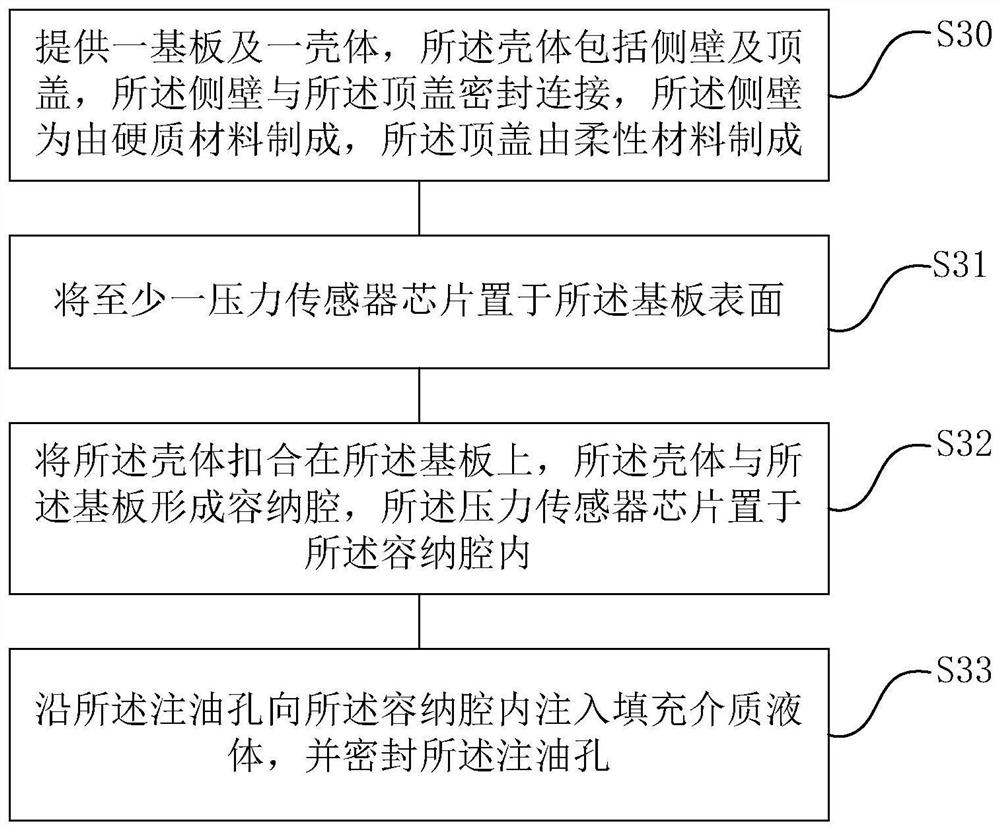

[0024] The specific implementation of the medium-isolated pressure sensor and its manufacturing method provided by the present invention will be described in detail below with reference to the accompanying drawings.

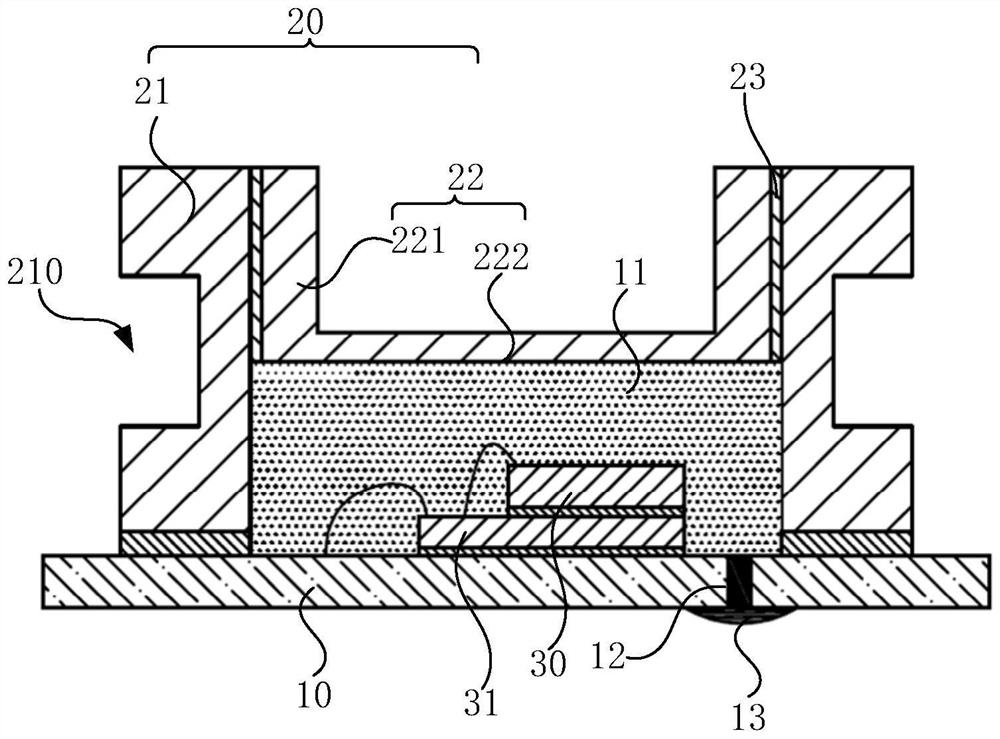

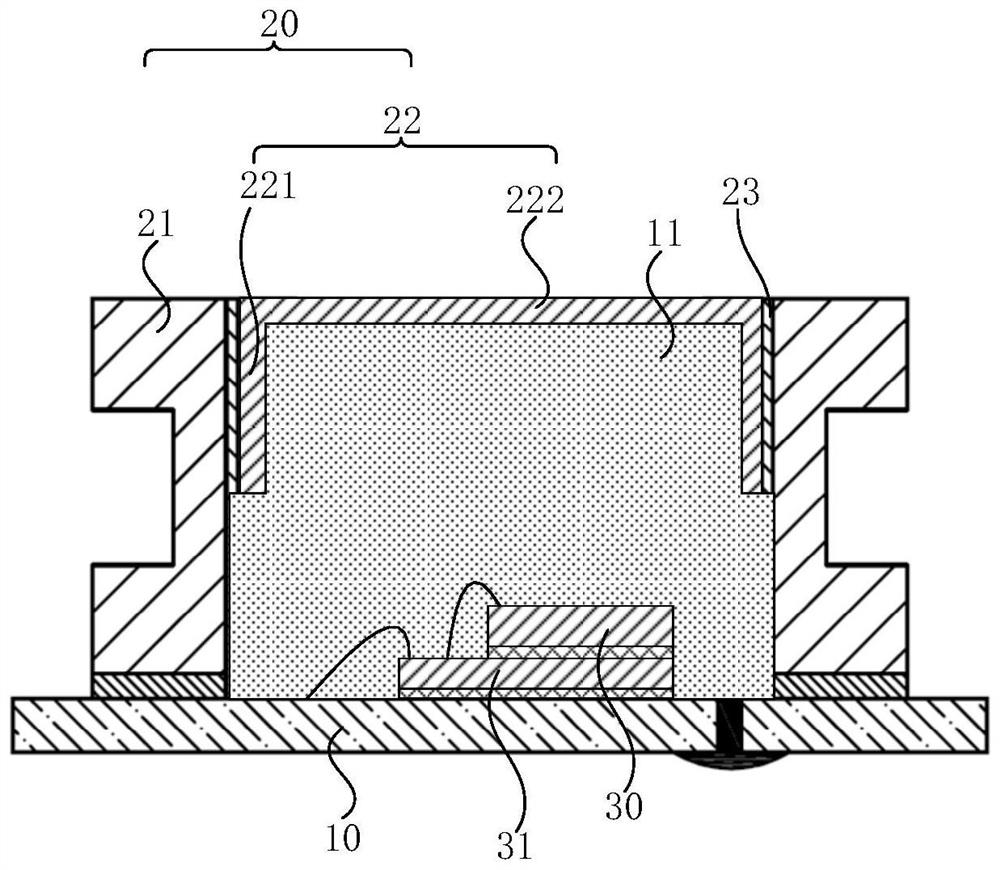

[0025] figure 1 is a schematic structural diagram of the medium-isolated pressure sensor provided by the first embodiment of the present invention, please refer to figure 1 , The medium-isolated pressure sensor of the present invention includes a substrate 10, a housing 20, at least one pressure sensor chip 30 and a medium liquid.

[0026] The substrate 10 includes but not limited to a ceramic circuit board or a printed circuit board. Electrical connection lines are provided in the substrate 10 to electrically connect the pressure sensor chip 30 with the outside. For example, in this embodiment, the substrate 10 is a ceramic circuit board, and an electrical connection circuit (not shown in the drawings) is disposed therein to electrically connect the pressure s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com