Oil seal reliability verification method

A verification method and reliability technology, applied in strength characteristics, test wear resistance, measuring devices, etc., can solve problems such as inability to conduct reliability tests, achieve the effect of reducing test time and improving verification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a method for verifying the reliability of an oil seal, which includes the following steps:

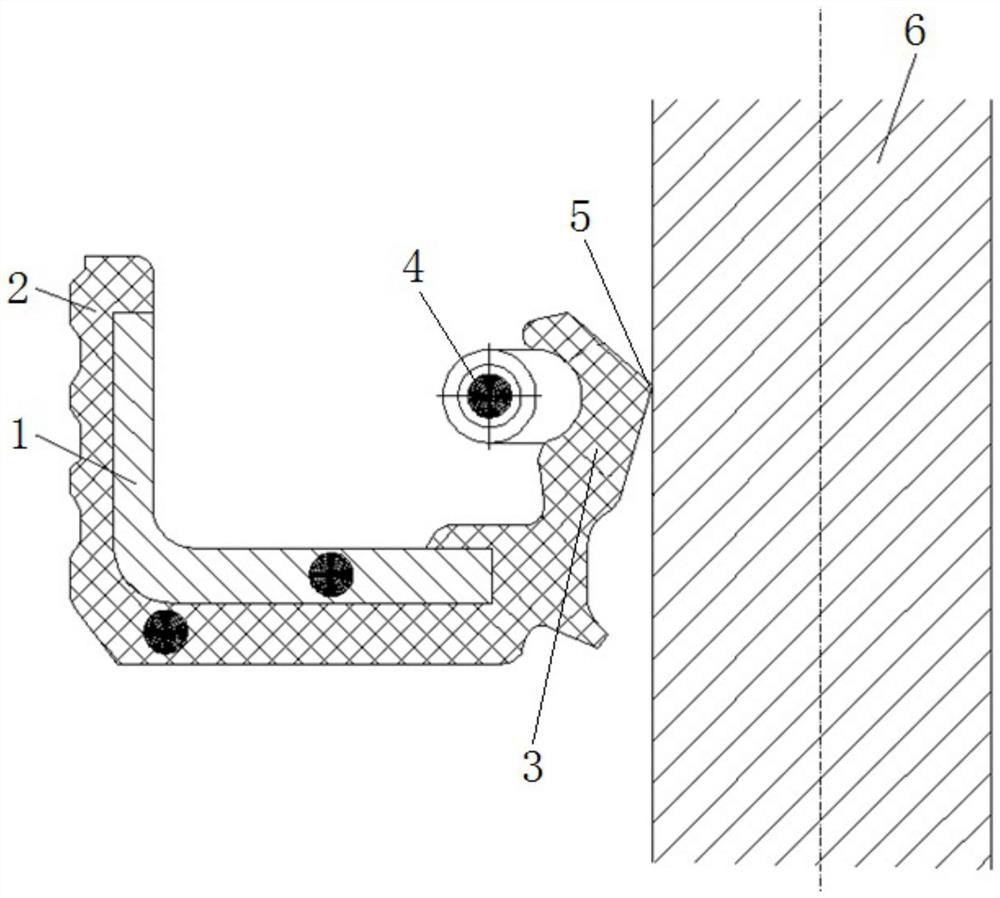

[0030] S1, fix the clamp of the oil seal to be tested on the test bench, and the lip of the oil seal to be tested is in interference fit with the rotating shaft on the test bench.

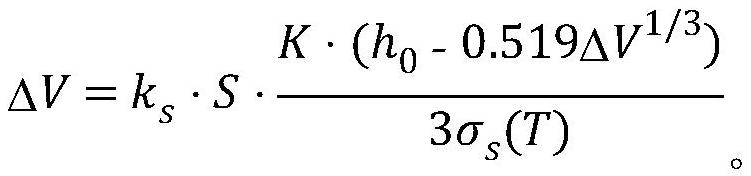

[0031] S2. Carry out the wear test under the set test condition, the set test condition is that the working temperature of the oil seal to be tested is 150°C. From the wear formula of the oil seal, the slip distance S and the yield strength σ of the material can be obtained s (T) is directly proportional, the actual operating temperature of the oil seal is T1, and the test temperature is increased to T2, then the yield strength of the oil seal material is changed from σ s1 reduced to σ s2 , the test time can be shortened to the original σ while keeping the wear amount ΔV constant s2 / σ s1 , so that the reliability condition has been strengthened and accelerated.

[0032] The materi...

Embodiment 2

[0033] Embodiment 2, a method for verifying the reliability of an oil seal, which includes the following steps:

[0034] S1, fix the clamp of the oil seal to be tested on the test bench, and the lip of the oil seal to be tested is in interference fit with the rotating shaft on the test bench.

[0035] S2. Carry out the wear test under the set test condition, the set test condition is that the spring stiffness of the oil seal to be tested is twice the spring stiffness of the oil seal used in the actual vehicle. From the wear formula of the oil seal, it can be concluded that the sliding distance S is inversely proportional to the stiffness K of the oil seal spring. By changing the stiffness of the oil seal spring through the test tool, it is also possible to reduce the moving distance year-on-year while keeping the wear amount ΔV unchanged. The purpose is to further reduce the time of reliability verification and improve the verification efficiency.

[0036] The springs of oil ...

Embodiment 3

[0037] Embodiment 3, a method for verifying the reliability of an oil seal, which includes the following steps:

[0038] S1, fix the clamp of the oil seal to be tested on the test bench, and the lip of the oil seal to be tested is in interference fit with the rotating shaft on the test bench.

[0039] S2, the wear test is carried out under the set test conditions. The set test conditions are that the initial radial compression of the oil seal to be tested is 3.5mm. In order to prevent oil leakage, the oil seal is in a compressed state after mating with the rotating shaft. The initial radial compression is designed to be 1.5mm. From the wear formula of the oil seal, the slip distance S and the initial radial compression h of the oil seal can be obtained 0 Inversely proportional, increasing the initial radial compression of the oil seal by increasing the diameter of the shaft in contact with the oil seal can also achieve the purpose of reducing the moving distance year-on-year w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com