Direct heat dissipation type high-strength U-shaped bus duct

A heat-dissipating, high-strength technology, used in cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems of inconvenient installation, poor heat dissipation, time-consuming and laborious, etc., and achieve the effects of convenient installation, increased strength, and short assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

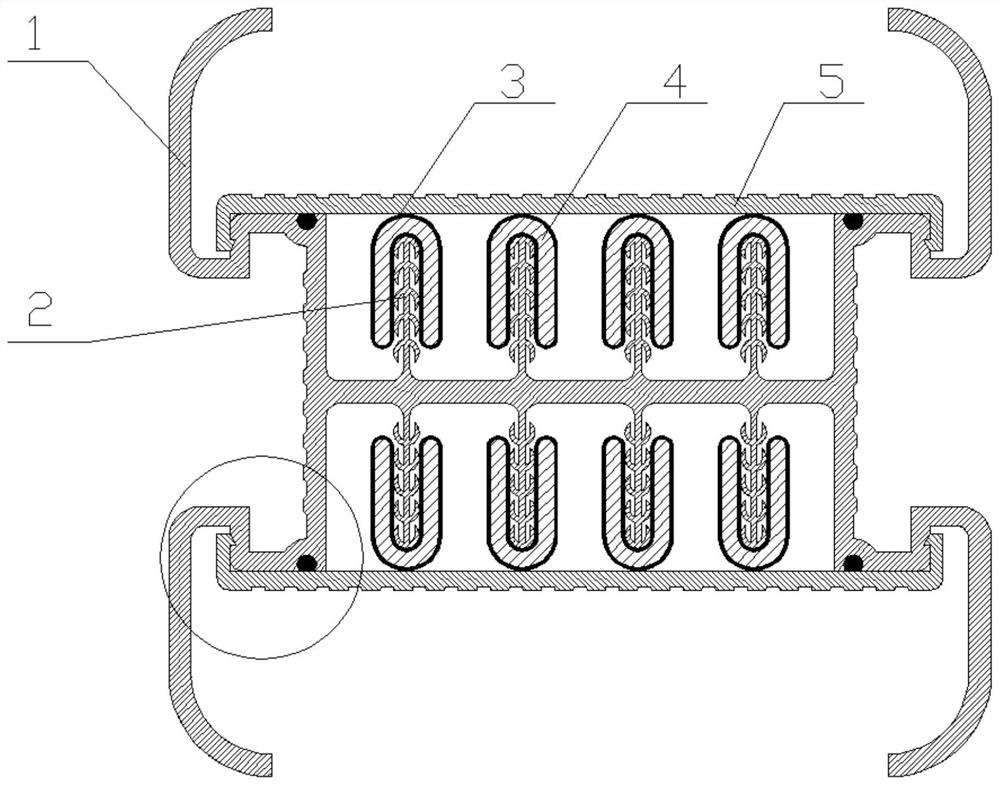

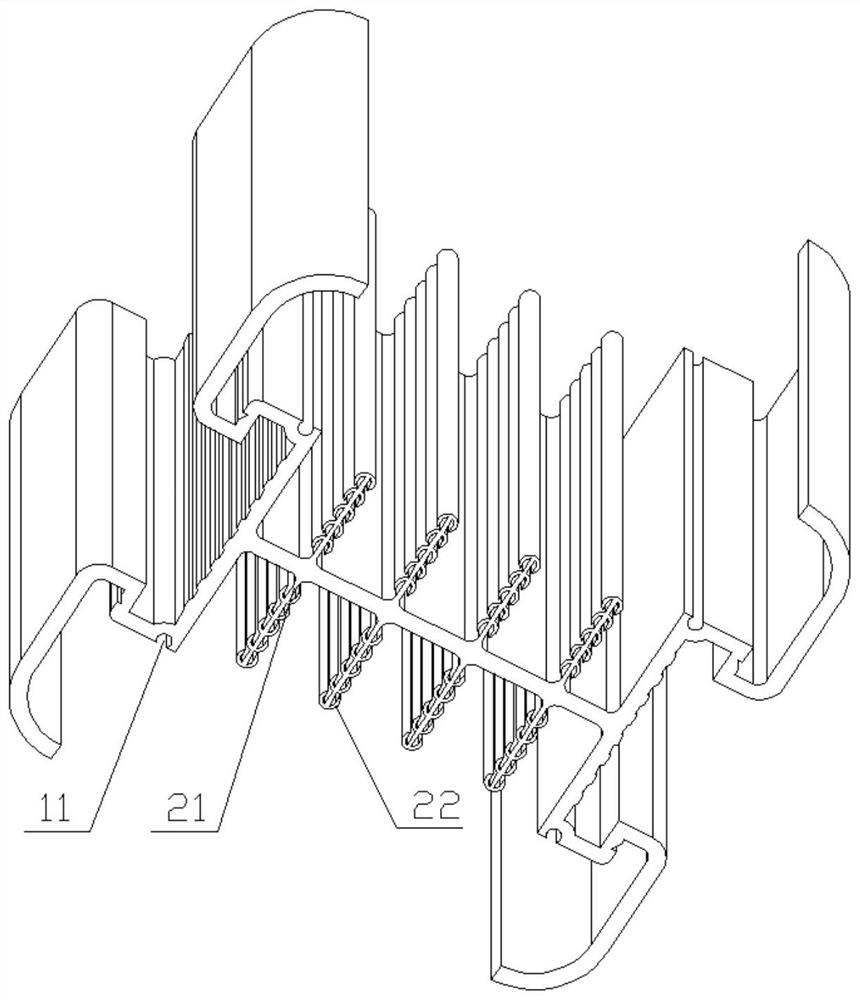

[0024] Example: see figure 1 , a direct heat dissipation high-strength U-shaped busway, including busbar side panels 1 and busbar cover panels 5; please refer to figure 2 , the busbar side plate 1 is an integral welded structure, the busbar side plate 1 includes a conductor fixed heat sink 2 arranged oppositely and a U-shaped bus conductor 4 clamped on the conductor fixed heat sink 2; the outer surface of the U-shaped bus conductor 4 is arranged With bus insulator 3;

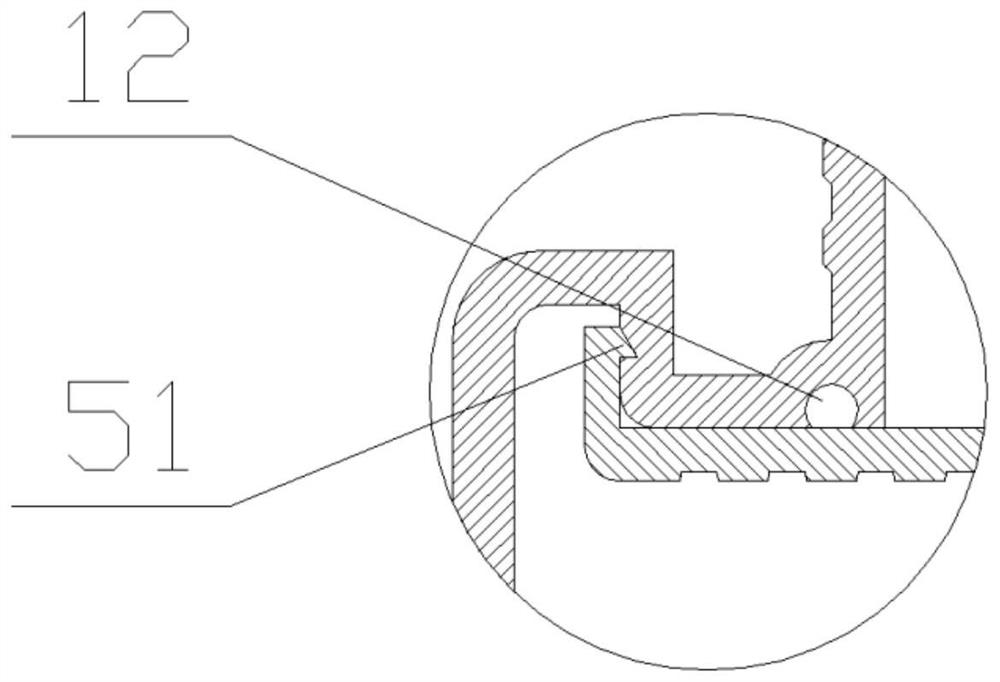

[0025] see image 3 , the busbar cover plate 5 is provided with a hook 51, which is engaged with the card slot provided on the busbar side plate 1; the installation is convenient, the assembly time is short, and no rivets and screws are needed;

[0026] The conductor fixed radiator 2 is a strip-shaped reinforcing rib 21; several groups of C-shaped ribs 22 are welded on the reinforcing rib 21; The shape adjustment of the U-shaped bus conductor 4 avoids the deformation effect of the U-shaped bus conductor 4 du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com